Rotary contact socket and plug

A socket plug, contact technology, applied in the direction of contact parts, connections, two-part connection devices, etc., can solve the problems of poor contact between sockets and plugs, increase contact resistance, loose sockets and plugs, etc., to ensure long-term good contact, The effect of reducing the space occupation and increasing the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

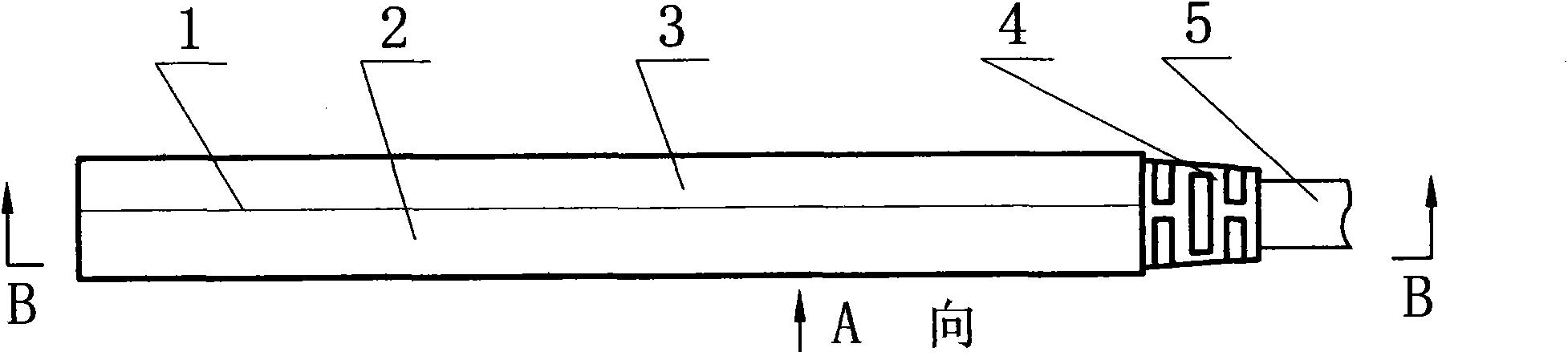

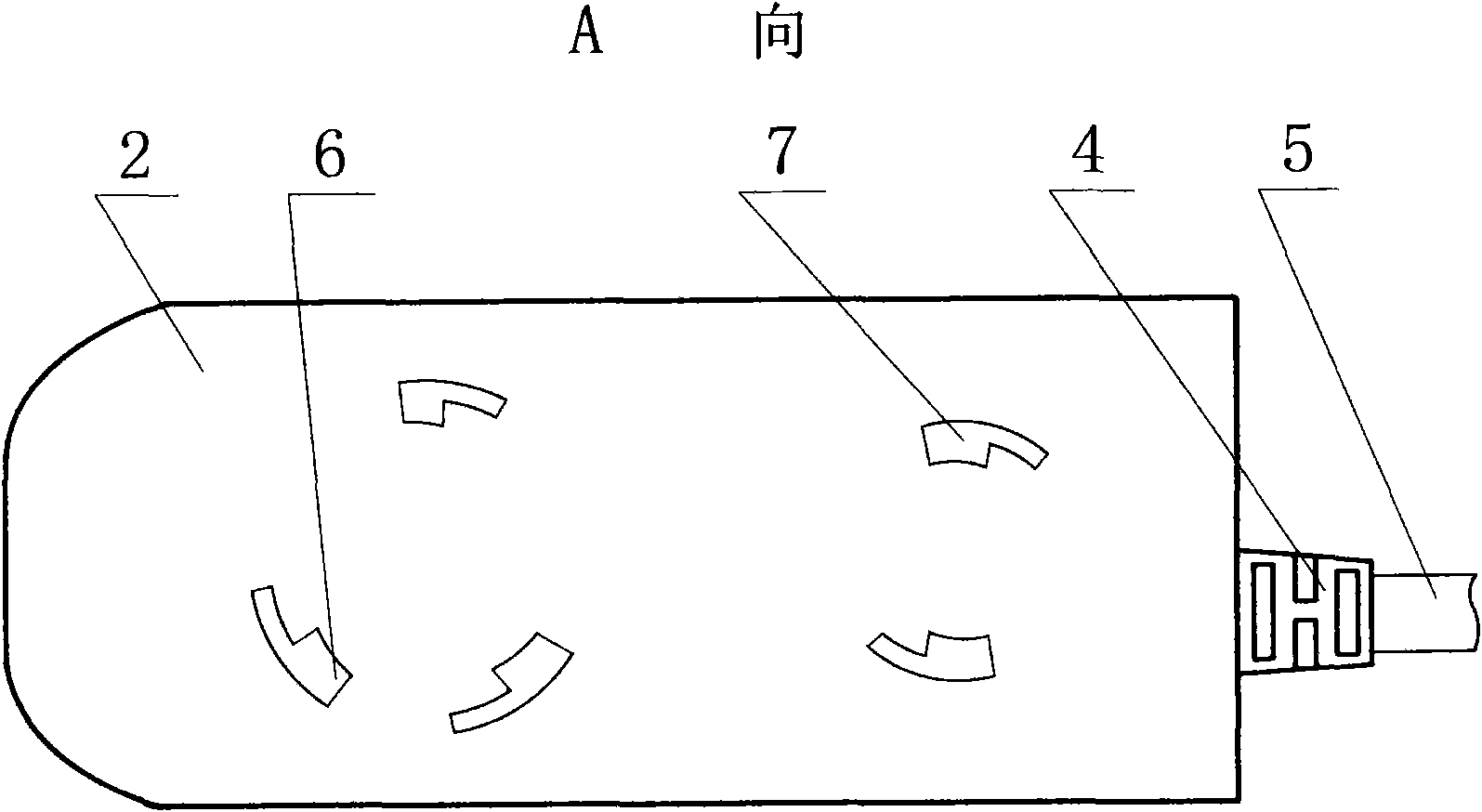

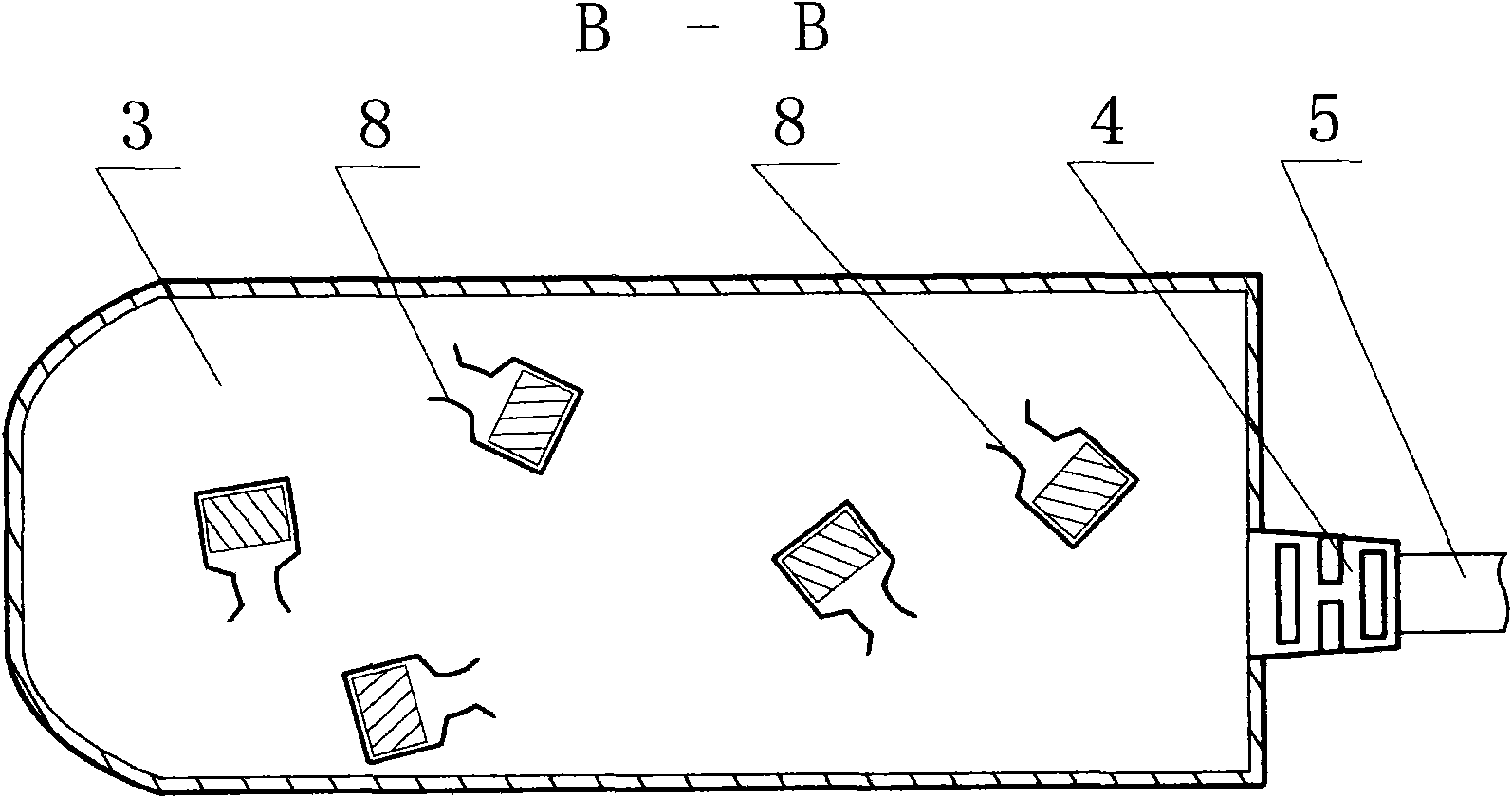

[0018] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a rotary contact socket plug includes: a socket 1 , a three-pole plug 9 , and a two-pole plug 13 . The socket 1 is composed of a front shell 2 and a rear cover 3. The power supply lead sheath 4 is set on the power lead 5 and fixed on the front shell 2; there are three three-pole jack slides 6, and two-pole jack slides 7 is 2, and is all located on the front shell 2 panel; Horizontal electrode clip spring 8 is 5 altogether, is lying and fixed in the front shell 2, and slides with three-pole jack slideway 6, two-pole jack respectively The slides of the jacks on the road 7 correspond to each other; the three-pole stepped insert piece 10 is 3 pieces, the three-pole power supply lead wire sheath 11, and the three-pole power supply lead wire 12 are all fixed on the three-pole plug 9; the two-pole stepped insert piece 14 is 2 pieces, and the two-pole power lead she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com