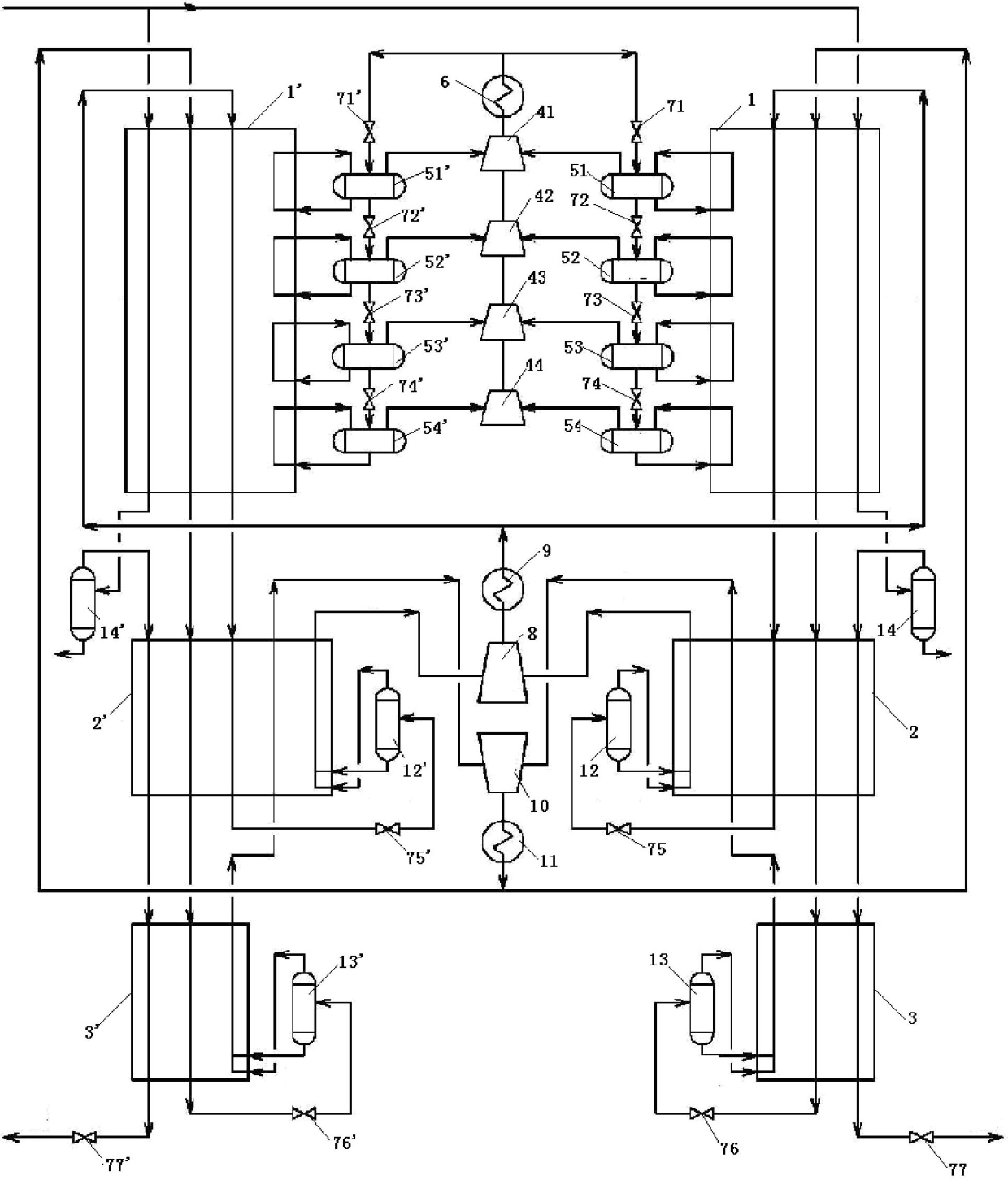

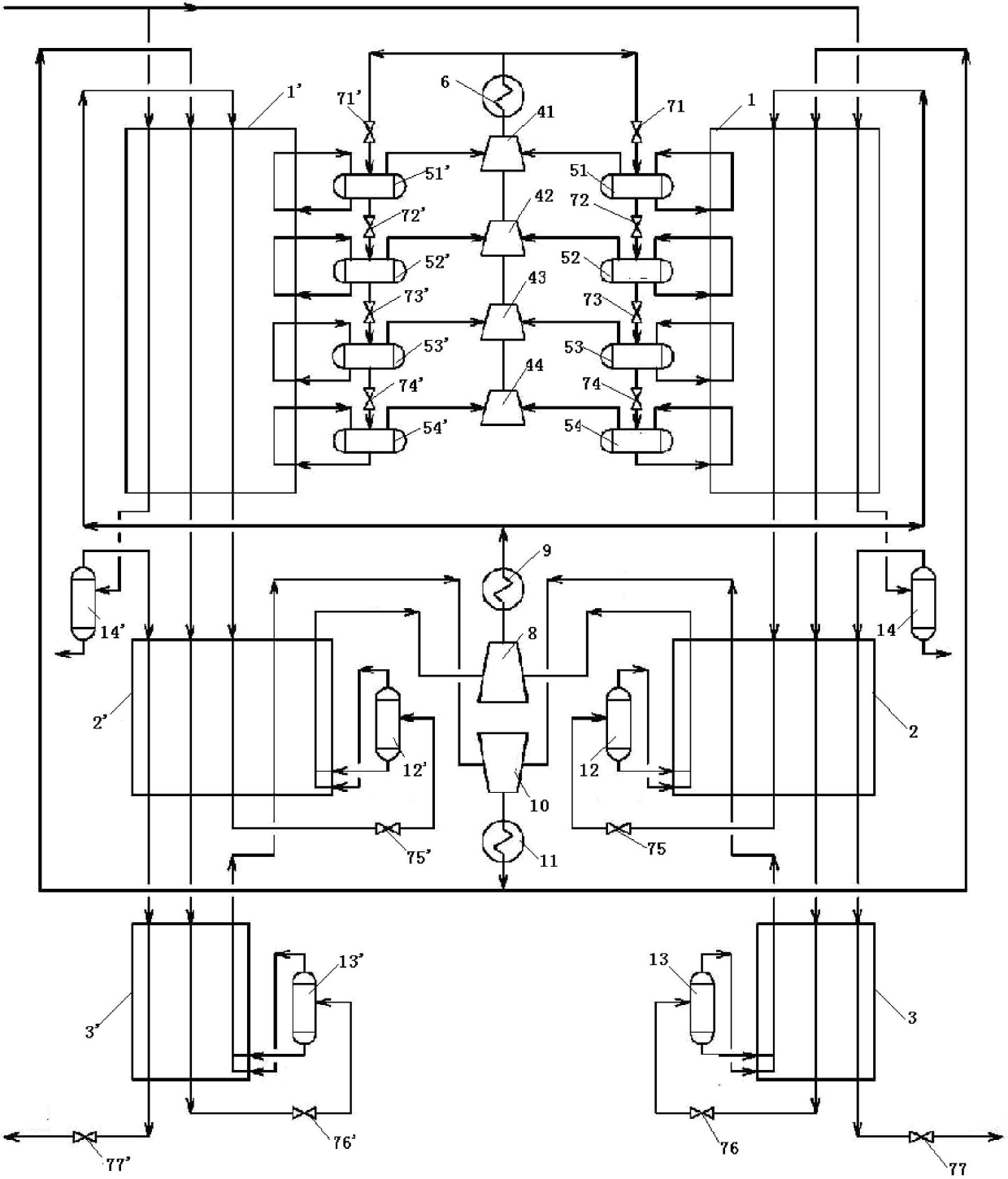

Propane pre-cooling double-mixing refrigerant serial-connection liquefaction system

A mixed refrigerant and propane precooling technology, which is applied in the field of natural gas liquefaction, can solve the problems of equipment investment waste, poor heat transfer performance, and high dependence on imported equipment, and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

[0016]The propane pre-cooling dual mixed refrigerant series liquefaction system provided by the present invention includes a pre-cooling cold box a1 and a pre-cooling cold box b1', a liquefaction cold box a2 and a liquefaction cold box b2', a cryogenic cold box a3 and a cryogenic cold box b3 ', propane pre-cooling cycle mechanism, mixed refrigerant liquefaction cycle mechanism and mixed refrigerant cryogenic cycle mechanism; propane pre-cooling cycle mechanism includes propane compressor a41, propane compressor b42, propane compressor c43 and propane compressor connected in sequence d44; the outlet of the propane compressor a41 is respectively connected to the propane gas-liquid separation tank a51 and the propane gas-liquid separation tank a'51' through two pipelines, and the propane gas-liquid sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com