Dynamic setting method for rolling roller gap through hot rough rolling

A setting method and roll gap technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of low speed, low precision, and failure of hydraulic cylinder median wear, so as to reduce cylinder wear and improve rolling. Efficiency and the effect of ensuring adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

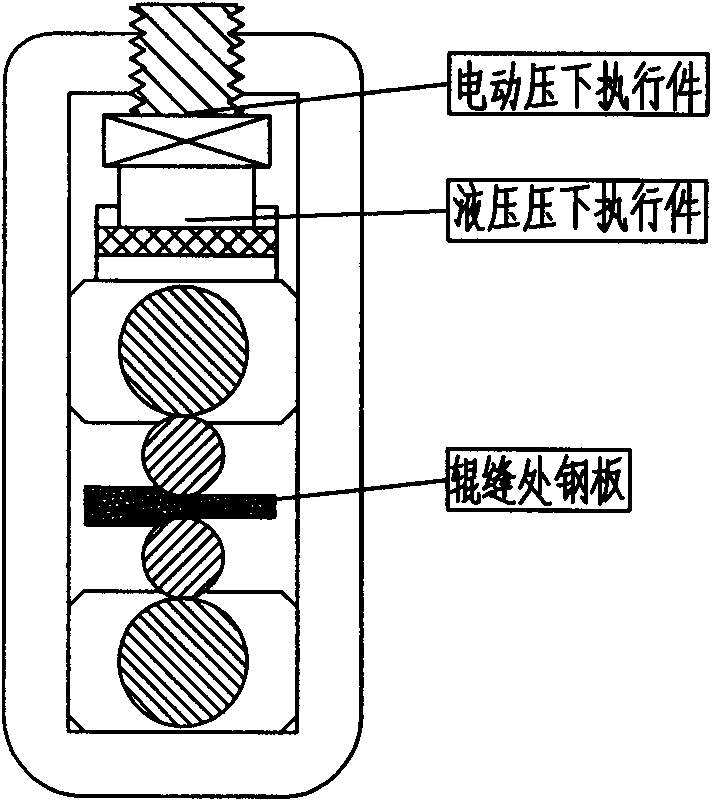

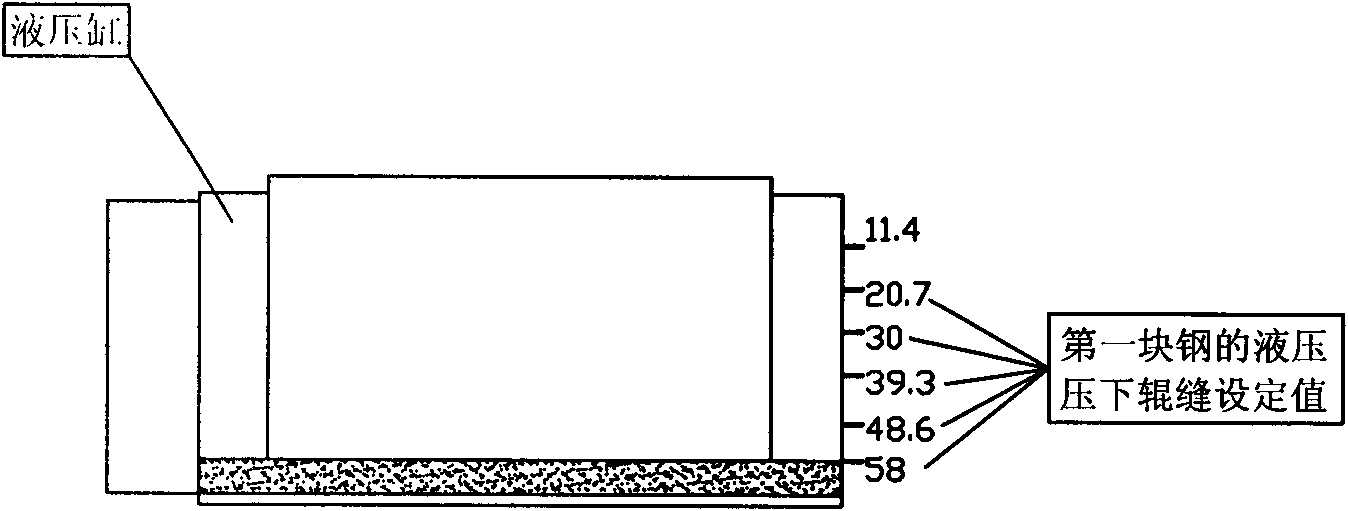

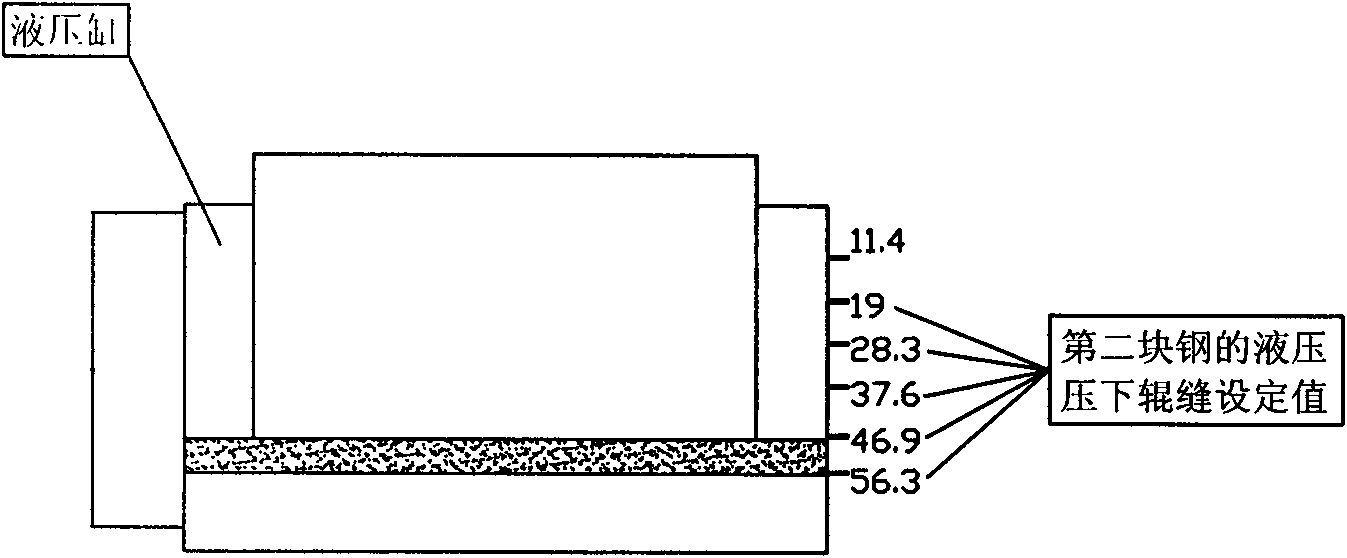

[0022] The method for dynamically setting the hot rough rolling roll gap in this embodiment is described by taking the existing rough rolling reversing rolling mill as an example. The electric and hydraulic pressing structure of the rolling mill is as follows figure 1 As shown, its Mechanical stroke of hydraulic cylinder Lmax is 60mm, hydraulic Cylinder soft limit value R is set to 2mm. The setting method of this embodiment assumes that there are 20 steel coils in actual operation, the ID numbers of the steel coils are 20072923010-20072923019, the steel types are all SPHC, the original thickness of the slab is 170mm, and the thickness of the rough rolling intermediate billet is required to be 38mm. Five passes (that is, the total number of rolling passes N=5) are rolled, and the preset total roll gap setting values Lz1, Lz2, Lz3, Lz4 and Lz5 of the five passes are 100mm, 84mm, 68mm, 52mm and 38mm respectively. The flow of the setting method in this embodiment is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com