Vacuum-state centrifugal filtering and dehydrating device for lubricating oil

A technology of filtration dehydration and centrifugal filtration, which is applied in the direction of liquid separation, separation method, liquid separation auxiliary equipment, etc. It can solve the problem of low filtration accuracy of jet centrifuge, inability to filter emulsified water of lubricating oil, inconvenience of transportation and movement and other problems, to achieve the effect of convenient and fast transportation and movement, light weight and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

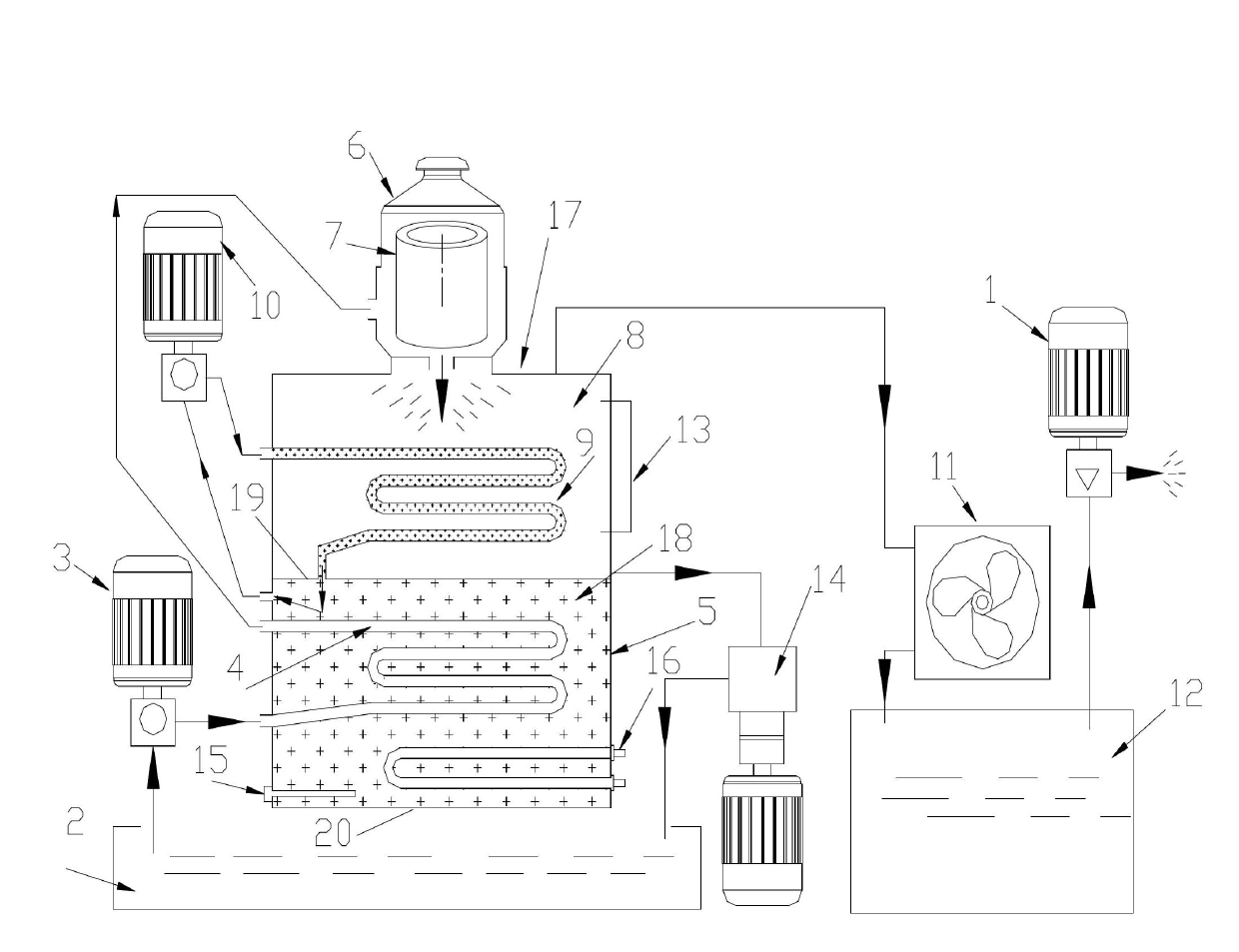

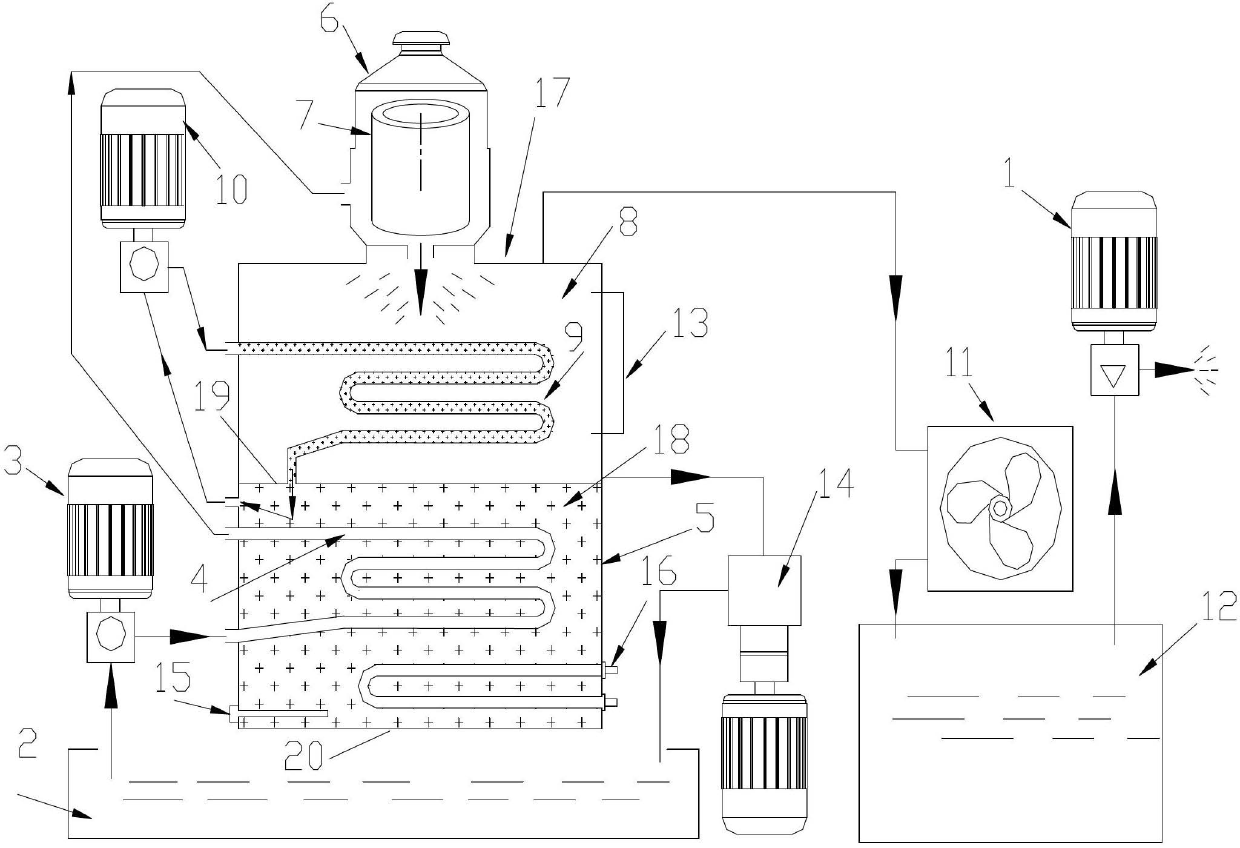

[0016] Attached below figure 1 An embodiment of the present invention is described.

[0017] The lubricating oil vacuum state centrifugal filter dehydration device has an integrated tank body 17, and the integrated tank body 17 is composed of a tank type vacuum generator 8 and a heat transfer oil heating device 5. Specifically, the heat transfer oil heating device 5 includes Heat-conducting oil tank 20, heat-collecting metal coil 4, heat-conducting oil 18 and electric heater 16, the heat-conducting oil 18 is filled with heat-conducting oil tank 20, and the heat-collecting metal coil 4 and electric heater 16 are all placed in the heat-conducting oil tank Inside the body 20 , the oil tank 2 is connected to the inlet end of the heat collecting metal coil 4 through the oil pump 3 , and the outlet end of the heat collecting metal coil 4 communicates with the centrifugal filter device 6 . The tank-type vacuum generator 8 is located above the heat-conducting oil heating device 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com