Intelligent control system for plant non-tube rapid propagation based on Internet of Things

An intelligent control system, the technology of the Internet of Things, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of high equipment cost, limited crop types, poor applicability of seedlings, etc., to reduce equipment costs and management costs. , quick and easy access and management, precise control of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

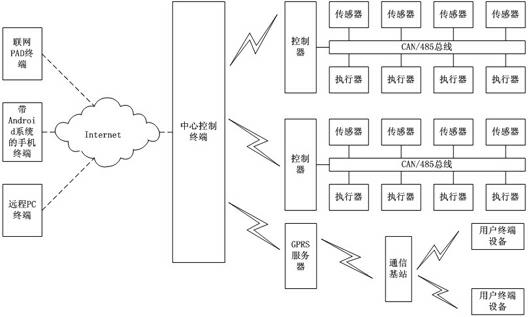

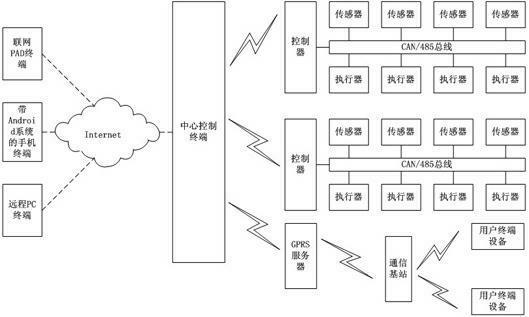

[0018] like figure 1 As shown in the figure, an IoT-based non-test tube fast-growing intelligent control system for plants includes a central control terminal, one or more controllers, one or more sensors, one or more actuators, one or more servers and one or more A plurality of user networking terminal equipment, the user networking terminal equipment is connected with the central control terminal through the Internet, and the central control terminal is respectively connected with the controller and the server through a communication module, and the communication module includes a wired communication module or a wireless communication module, preferably RF or zigbee wireless communication module; the server is connected to the user terminal equipment, and one or more communication base s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com