Ultra-low temperature freezer

A technology of ultra-low temperature and freezer, which is applied in coolers, household refrigeration devices, household refrigerators, etc. It can solve the problems of reduced working efficiency of refrigerators, poor insulation effect of inner doors, and easy deformation of inner doors, so as to achieve less cooling loss , The level of heat preservation is improved, and the effect of refrigeration is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

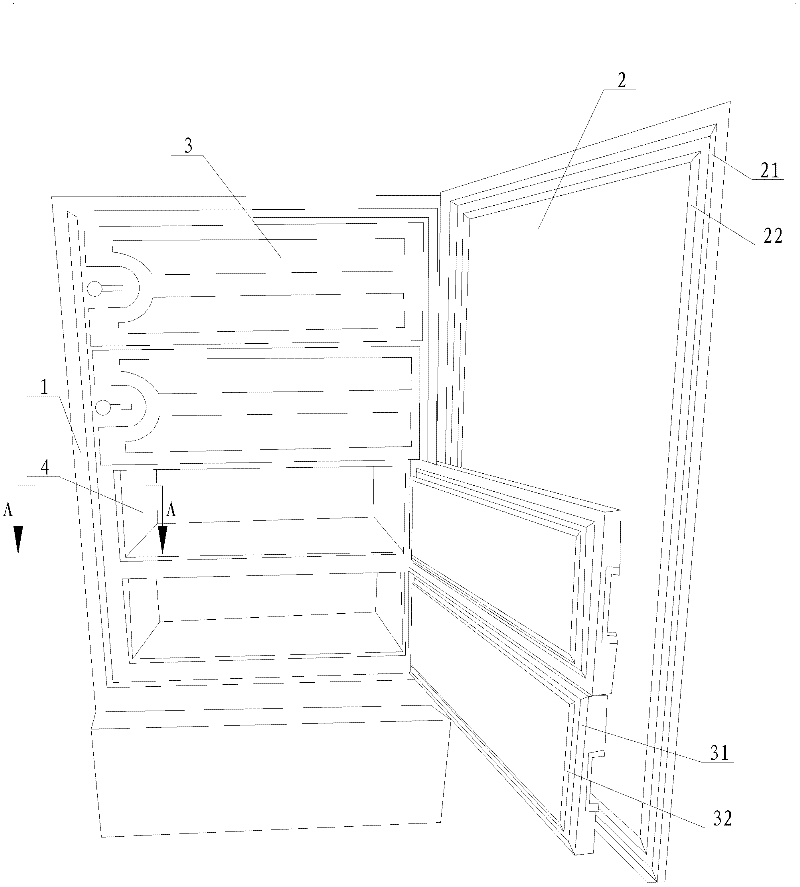

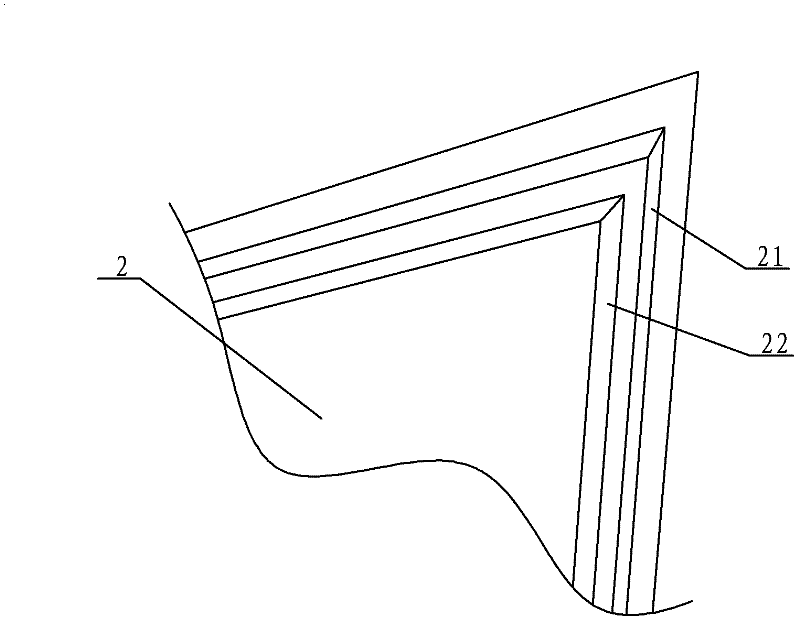

[0028] Such as figure 2 As shown, two sealing strips are provided on the outer door 2, namely the first sealing strip 21 and the second sealing strip 22, and the first sealing strip 21 is provided on the outer edge of the outer door 2 where it is attached to the case 1, the number is In one circle, the second sealing strip 22 is arranged on the outer door 2 where it is attached to the cabinet opening connection structure 5, and the number is also one circle. The first sealing strip 21 and the second sealing strip 22 are integrally enclosed in a rectangular frame.

[0029] Such as image 3 As shown, two sealing strips are provided on the inner door 3, namely the third sealing strip 31 and the fourth sealing strip 32, and the third sealing strip 31 is arranged on the outer edge of the inner door 3 and is attached to the cabinet opening connection structure 5. The fourth sealing strip 32 is arranged on the inner door 3 where it is attached to the inner liner 4, and the number is als...

Embodiment 2

[0035] Such as figure 1 As shown, four sealing strips are arranged on the outer door, namely the first sealing strip and the second sealing strip, and both the first sealing strip and the second sealing strip are two. The first sealing strip is arranged on the outer edge of the outer door and The number of joints of the box shell is two circles, and the second sealing strip is arranged on the outer door and the joints of the cabinet opening connection structure. The number is also two circles. The first sealing strip and the second sealing strip form a rectangular frame as a whole .

[0036] Four sealing strips are arranged on the inner door, namely the third sealing strip and the fourth sealing strip, and the third sealing strip and the fourth sealing strip are two. The third sealing strip is arranged on the outer edge of the inner door and the cabinet. The number of the joints of the mouth connecting structure is two circles, the fourth sealing strip is arranged on the inner do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com