Novel vertical oil-less pump

An oil-free, vertical technology, used in pumps, pump components, rotary piston type/swing piston type pump components, etc., can solve the problems of easy wear of gears, heavy maintenance work, short life, etc., and achieve stable lubrication mechanism. , The effect of reducing maintenance costs and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

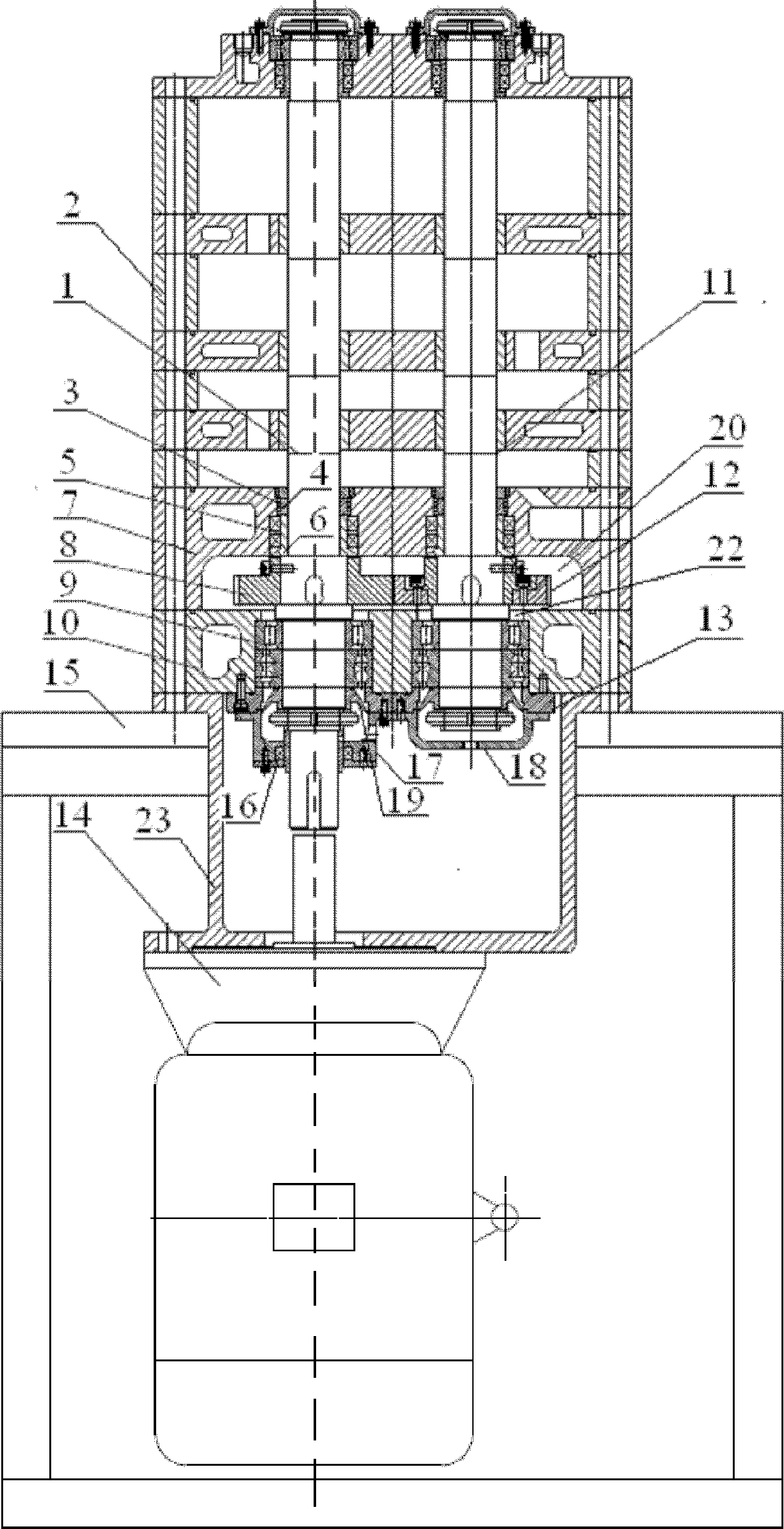

[0016] Such as figure 1 As shown, the novel vertical oil-free pump provided by the present invention includes a frame 15, a pump body arranged on the frame 15 and a motor 14 connected with the pump body. The first-stage pump chamber 2 and the transmission assembly that runs through the pump body. The transmission assembly includes a driving shaft 1 and a driven shaft 11 that are keyed to the output shaft of the motor 14. The transmission ends of the driving shaft 1 and the driven shaft 11 are respectively provided with bearings 9. Bearing 9 is installed in the through hole that offers on base 10, and the driving end of driving shaft 1 is also provided with driving gear 8, and the driving end of driven shaft 11 is provided with the driven gear 12 that meshes with driving gear 8. The main difference between the present invention and the existing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com