Assistance mechanism for bottom seaming machine of woven bag

A technology of assist mechanism and woven bag, applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control device, etc., can solve the problems of deviation of the woven bag, damage of the sewing machine, and the woven bag being hooked, etc., so as to increase the sewing speed and improve the sewing speed. Consistent quality and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

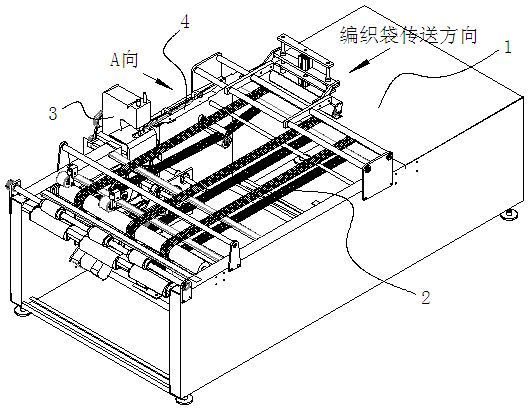

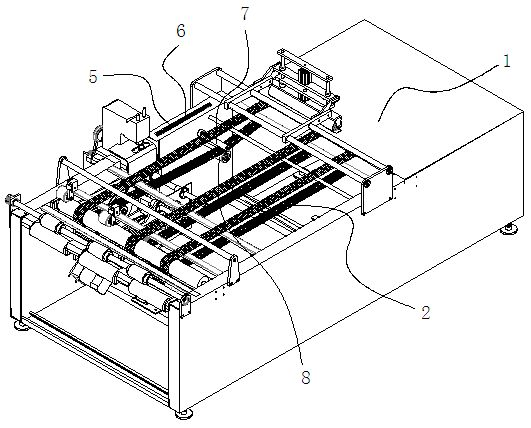

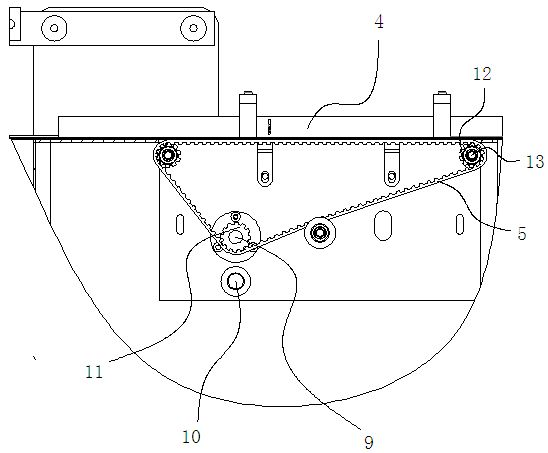

[0020] Embodiment: a kind of auxiliary mechanism of woven bag sewing machine such as figure 1 , figure 2 As shown, including the frame 1, the upper surface of the frame 1 is provided with several ring-shaped flat conveyor belts 2 with knurling on the inner and outer peripheral surfaces. The flat conveyor belt 2 is connected with the power device (blocked in the figure). The direction of rotation matches the conveying direction of the woven bag. The frame 1 is provided with a woven bag sewing machine 3 on the outside of several flat conveyor belts 2, and the frame 1 is provided with a crimping device 4 on the front side of the woven bag sewing machine 3. Frame 1 is provided with elongated hole 6 at the underside of crimping device 4, and synchronous belt 5 is arranged in elongated hole 6, as Figure 4 As shown, the outer peripheral surface of the synchronous belt 5 is knurled, such as figure 2 , image 3 As shown, a driving synchronous pulley 11 and two driven synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com