Programmable high speed automatic pipe cutting machine

A pipe cutting machine, automatic technology, applied in metal processing and other directions, can solve problems such as serious injury to workers, prone to accidents, inconvenient maintenance, etc., and achieve the effect of ensuring safety and health, high degree of automation, and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

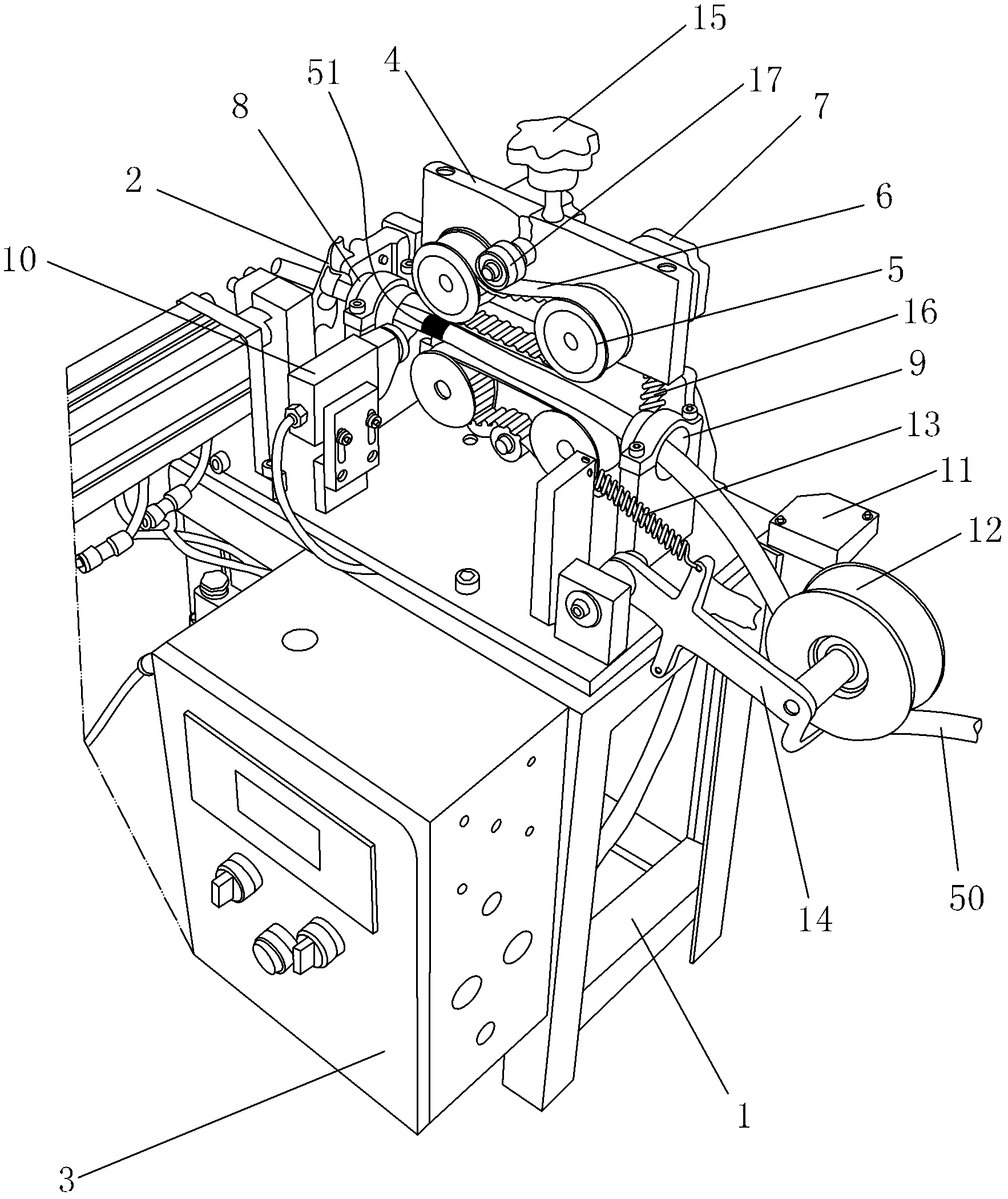

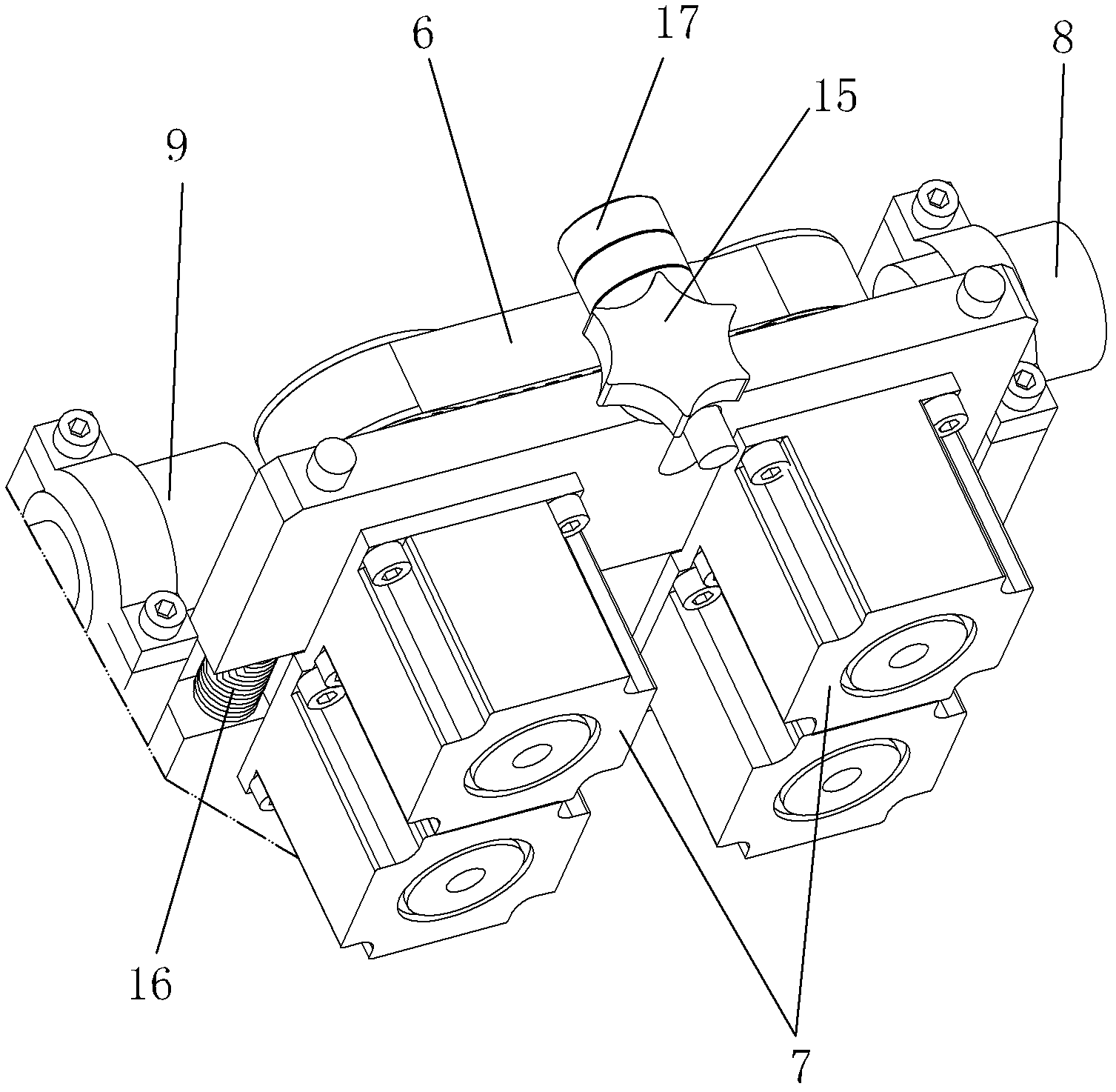

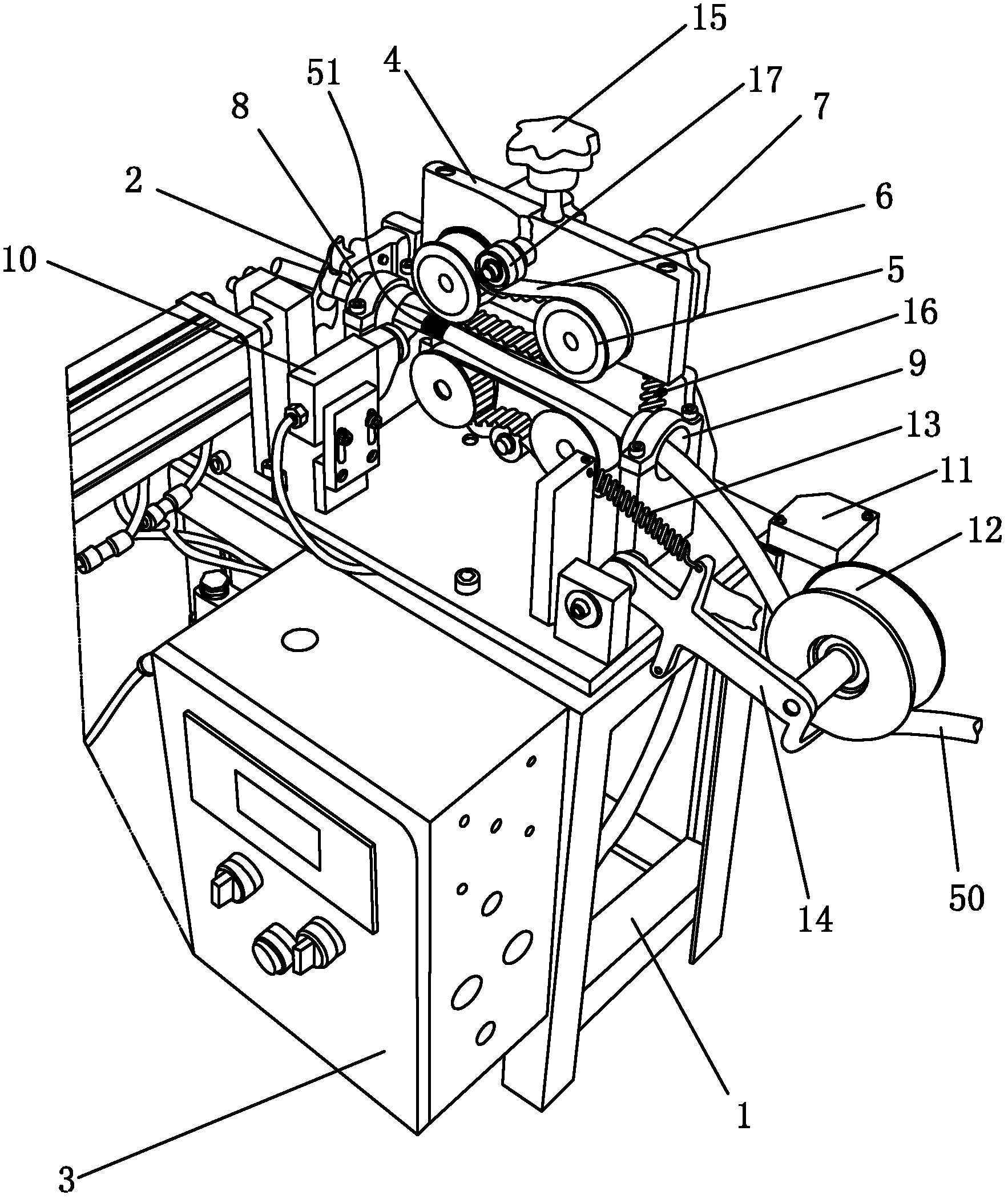

[0019] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0020] Programmable high-speed automatic pipe cutting machine, including a frame 1 and a cutting mechanism 2, a controller 3 and a pulley mounting frame 4 are arranged on the frame 1, and mutually parallel horizontally arranged on the same side of the pulley mounting frame 4 Two groups of belt pulleys 5 installed on the wheel shaft, two groups of belt pulleys 5 are set up and down and are equipped with synchronous belts 6 respectively, the wheel shafts of the two groups of belt pulleys 5 are driven by stepping motors 7 respectively, the two synchronous belts 6 between The center distance is adjustable, and the two ends of the two synchronous belts 6 are respectively provided with guide cylinders (8, 9) that can pass through the braided pipe, and one side of the inner side of the first guide cylinder 8 is provided with a color mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com