Cleaning equipment for single crystal growth furnace chamber

A technology for cleaning equipment and growth furnaces, applied in the field of single crystal growth furnace inner cavity cleaning equipment, which can solve problems such as dirt on the face, unsatisfactory cleaning effect, and stiff arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

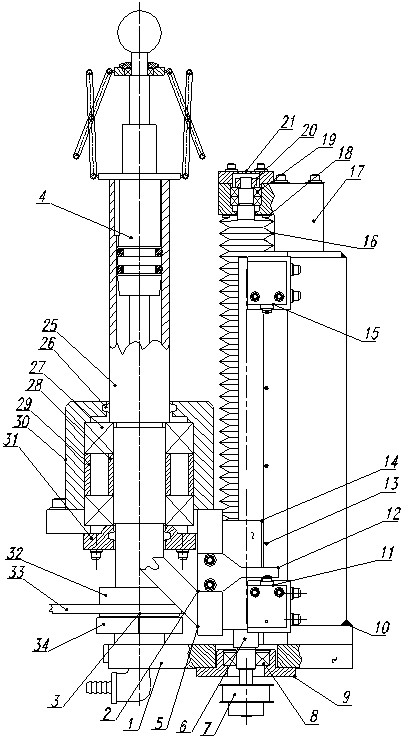

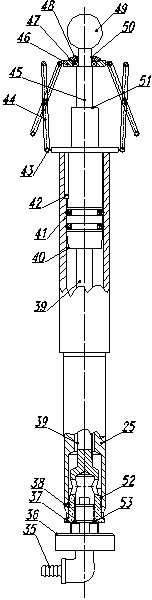

[0014] As shown in the figure, the single crystal growth furnace cavity cleaning equipment includes a base plate 1, a lifting assembly 2, a rotating assembly 3, and a water spraying assembly 4. The lifting assembly 2 is installed on the base plate 1, and the rotating assembly 3 is installed on the lifting assembly 2. On the elevating bracket, the water spray assembly 4 is installed on the sleeve shaft of the rotating assembly 3.

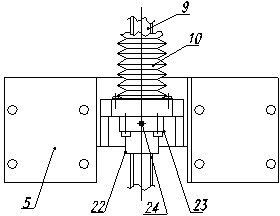

[0015] Among them, the lifting assembly 2 includes a lifting bracket 5, a lead screw 6, a pulley 7, a bearing 8, a bearing cover 9, a guide rail seat 10, a lower travel switch 11, a touch block 12, a linear guide rail 13, a ball guide rail 14, and an upper travel switch. 15. Protective cover 16, upper bearing seat 17, butt plate 18, upper bearing 19, lock nut 20, shaft cover 21, lead screw nut 22, lead screw nut flange 23, fastening screw 24, lifting bracket 5 through wire The rod nut flange 23 is connected with the lead screw nut 20 as a whole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com