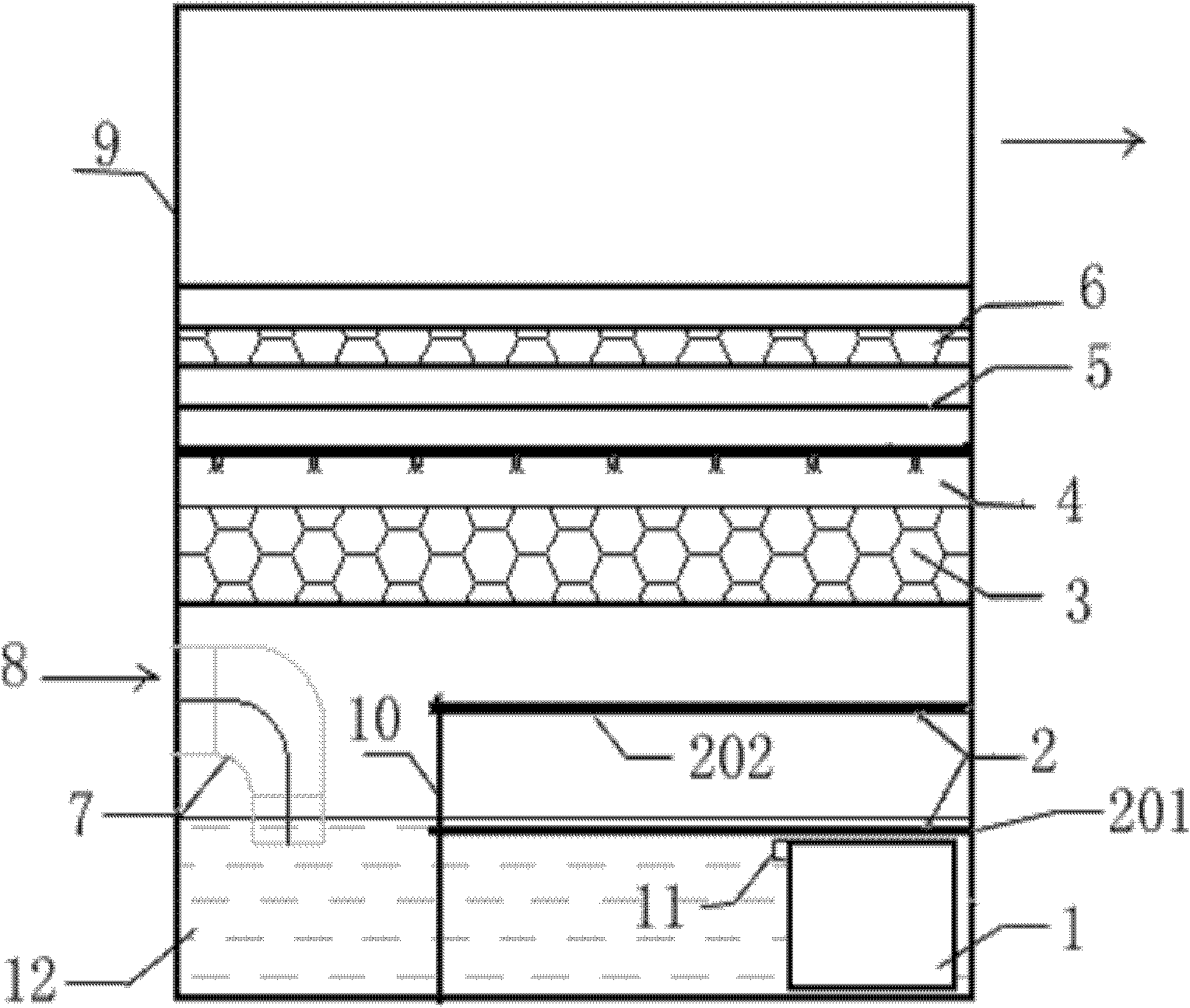

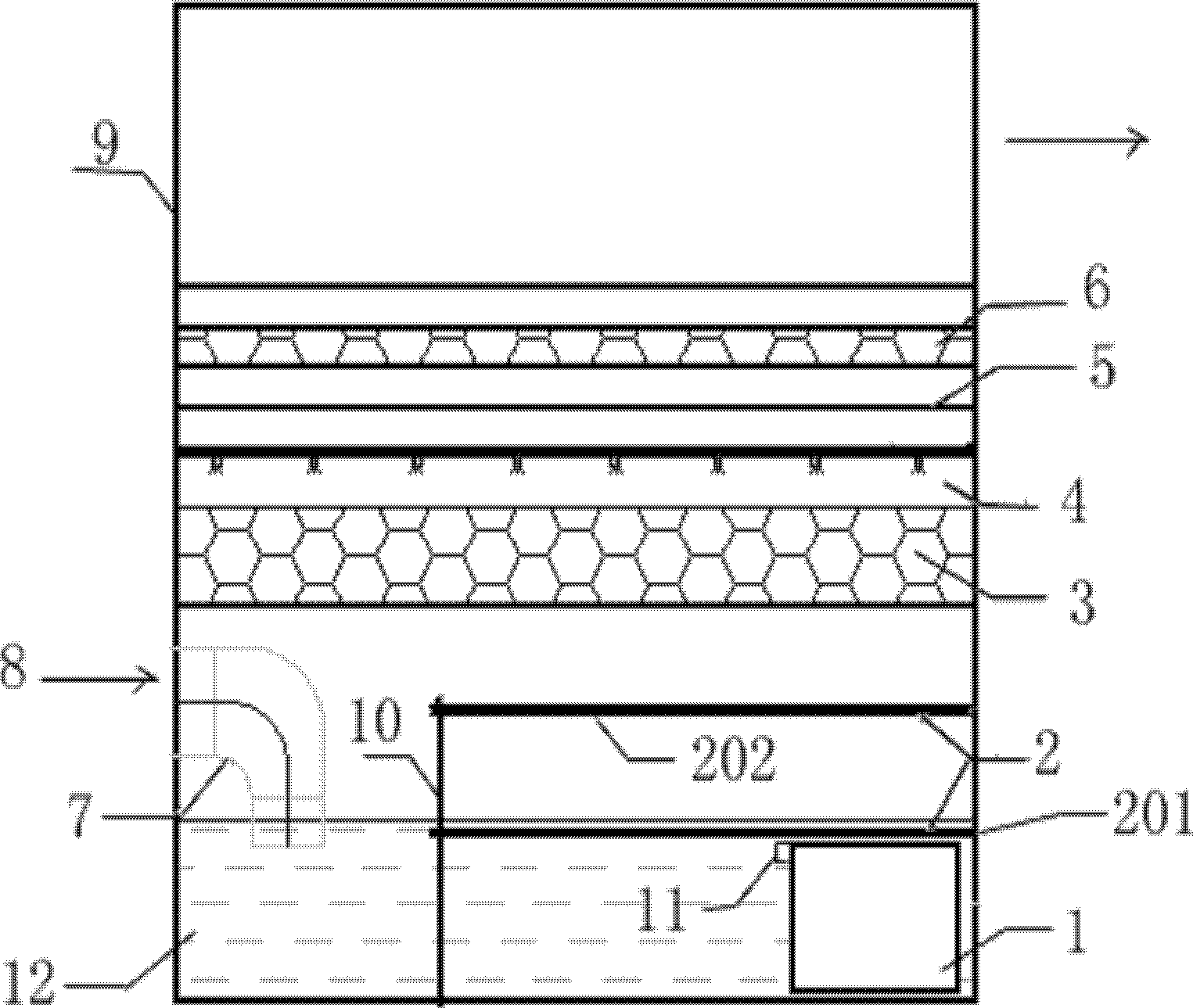

Waste gas treatment air purification device

An air purification device and waste gas treatment technology, applied in chemical instruments and methods, using liquid separation agents, and separation of dispersed particles, can solve the problems of industrial waste gas pre-treatment and post-treatment not being disclosed in detail, industrial waste gas containing dust, etc. Achieve the effects of prolonging the contact reaction area and time, not being saturated, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Treatment of organic waste gas from pesticide factories. The content of acetic acid and methyl ester in exhaust gas is 300-500mg / m 3 .

[0048] Device parameters: Dimensions: 1200×600×2200mm (length×width×height); motor power: 5.5Kw; total air volume: 4500cmh, wind speed: 18m / s;

[0049] The result after treatment is that the content of acetic acid and methyl ester in the exhaust gas is 2-5mg / m 3 , The odor removal rate is over 90-95%.

Embodiment 2

[0051] Removal of lipid waste gas in kitchen fume exhaust system. National emission standard is 2000mg / m 3 , the measurement result of this device is 0.18mg / m 3 .

Embodiment 3

[0053] Treatment of waste gas from benzene ring and its derivatives in chemical plants.

[0054] Device parameters: Dimensions: 2500×2200×2500mm (length×width×height); motor power: 15Kw; total air volume: 36000cmh, wind speed: 25m / s;

[0055] As a result of the treatment, the scavenging rate of the benzene ring and its derivatives was greater than 70%.

[0056] The invention has the characteristics of simple operation, convenient maintenance and integrated structure, greatly reduces the production cost, and realizes the thorough purification of toxic and harmful gases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com