Color-protecting processing method of freeze drying onion

A processing method and drying technology, applied in the field of color protection processing of natural green color, can solve problems such as excessive sulfite and metal ion residues, and achieve the effects of accelerating dehydration rate, ensuring safety, and inhibiting oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: All green onions

[0036] The color-protecting processing method of freeze-dried shallots of the present invention is realized through the following steps:

[0037] (1) The all-green medium-tube green onions picked in the controlled vegetable base are transported to the processing plant in about 4 hours, and are required to be put into pre-processing within 24 hours. The medium-tube shallots that are not processed in time after entering the factory are first put into the refrigerator (0~ 5°C). During processing, cut off the part with the white head of the root of the medium-tube spring onion, select and remove soft rot, rotten deterioration, disease spots, burnt tail and other impurities and foreign objects, and then wash it again.

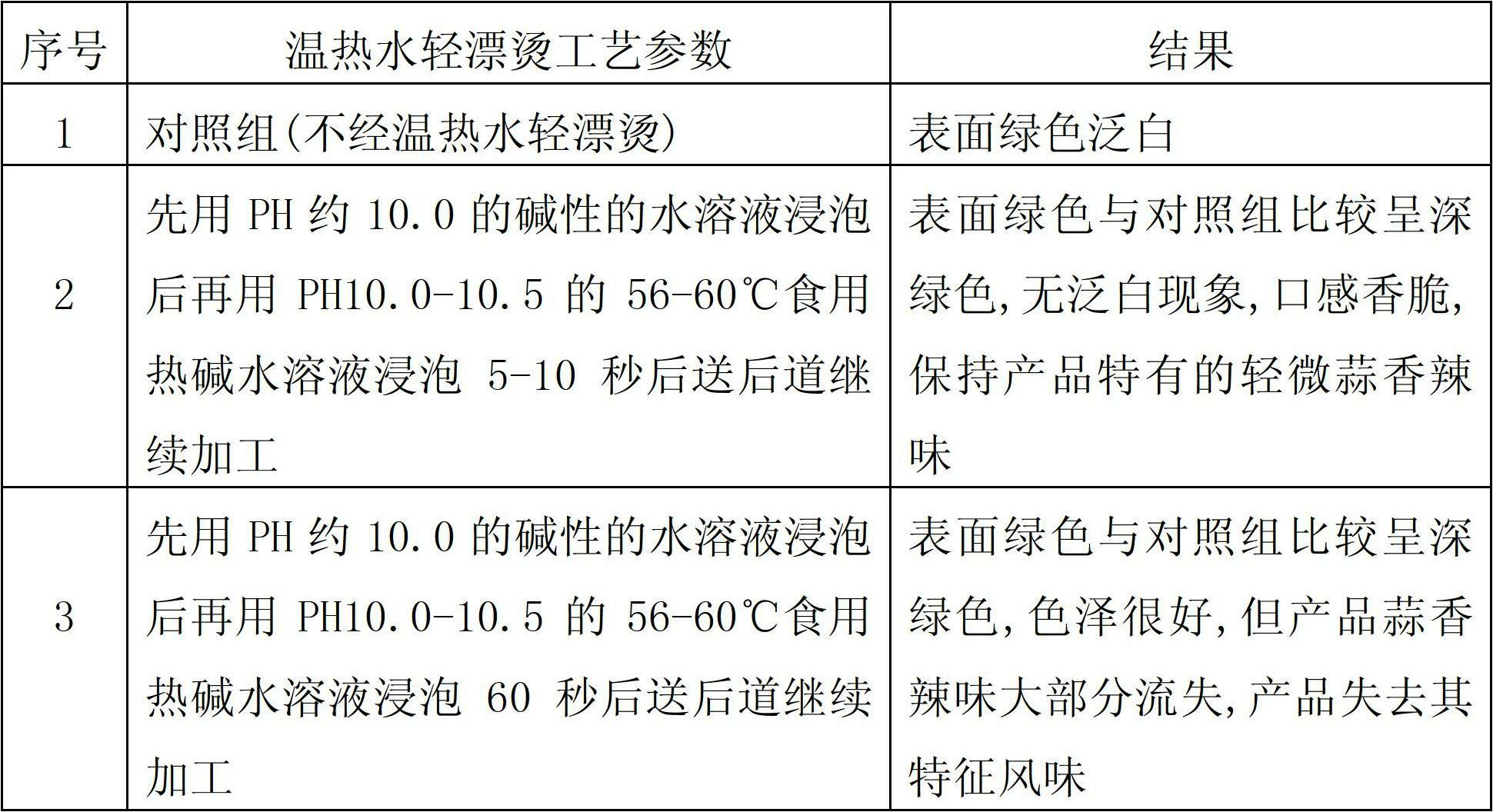

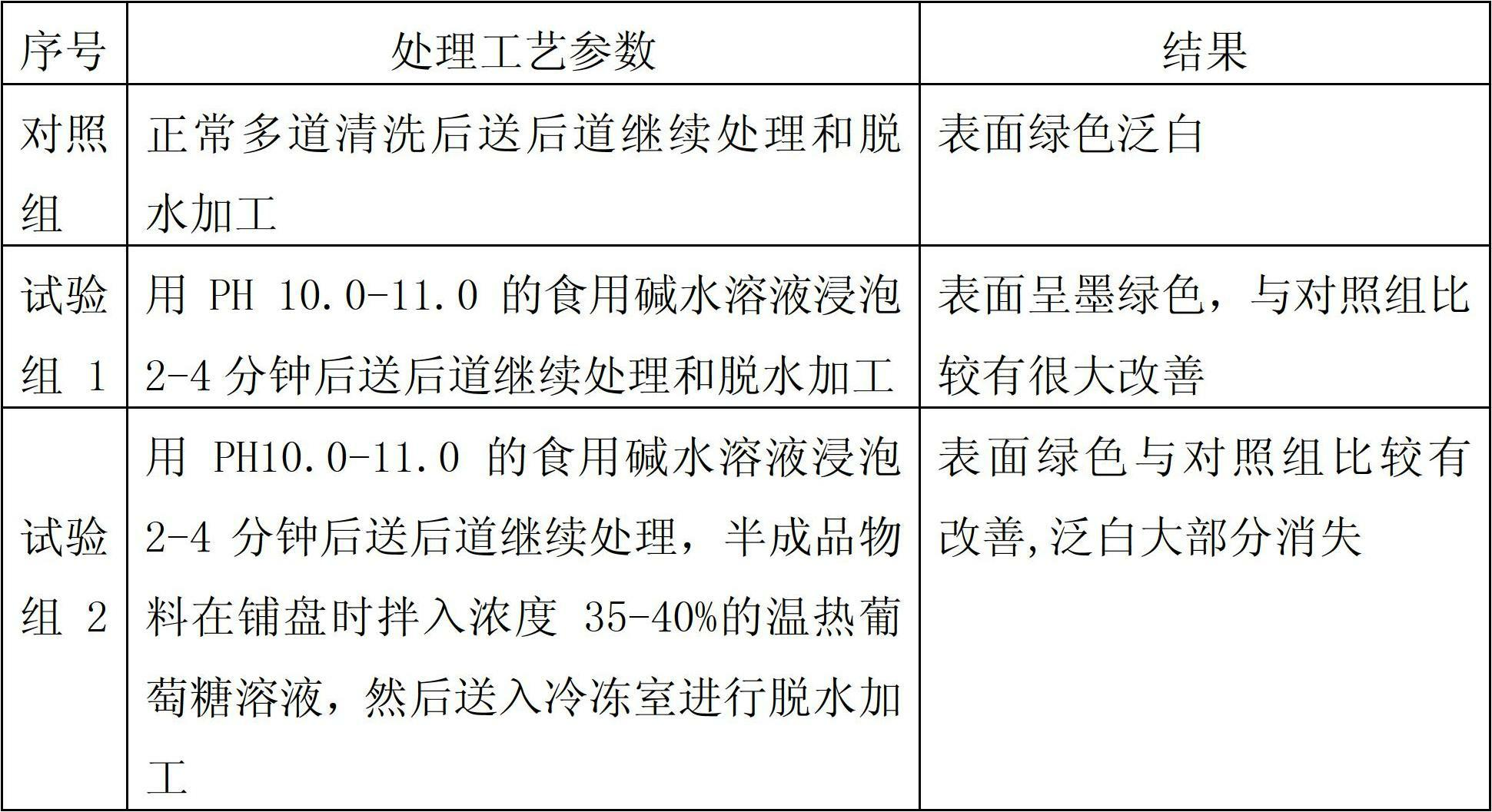

[0038] (2) Prepare 0.06~0.12wt% edible soda ash (soda) aqueous solution, control the pH to 9.0~11.0, neatly put the middle tube scallions treated in step (1) into the edible soda ash aqueous solution for 5~8 minutes, Then wash ...

Embodiment 2

[0045] Example 2: German shallots

[0046] The color-protecting processing method of freeze-dried shallots of the present invention is realized through the following steps:

[0047] (1) German shallots picked at the vegetable raw material base are transported to the processing plant in about 8 hours, and processing is required to start within 48 hours. Before processing, German shallots should be placed in a refrigerator (0-5°C). During processing, German onion raw materials are selected to remove soft rot, rotten deterioration, disease spots, burnt tails, impurities and foreign objects, and then washed once.

[0048] (2) Prepare 0.08~0.15%wt% edible soda ash (soda) aqueous solution, control pH 9.0~11.0, neatly put the German green onions treated in step (1) into the edible soda ash aqueous solution for 7~8 minutes, Then wash with running water 3 times. The edible soda ash aqueous solution is renewed after being used 4 to 5 times.

[0049] (3) Take clean tap water, heat the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com