Lithium battery anode material and method for improving cycle performance of battery

A positive electrode material and battery cycle technology, applied in battery electrodes, secondary battery charging/discharging, secondary batteries, etc., can solve the problems of fast capacity decay and failure to meet application requirements, and achieve high capacity retention and meet application requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

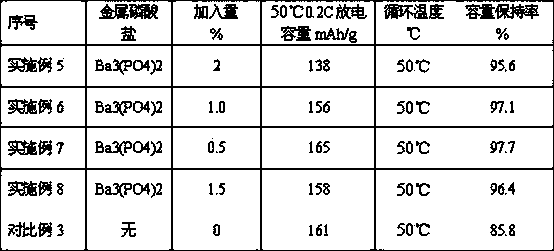

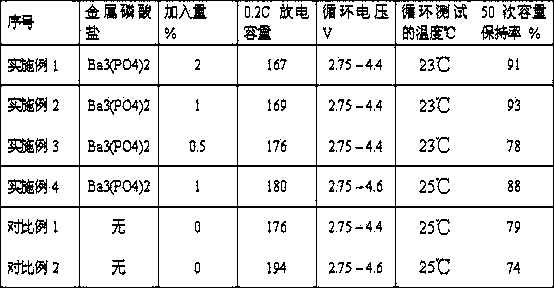

Embodiment 1

[0036] Embodiment 1: The lithium battery positive electrode material used in this embodiment is mainly composed of positive electrode active material and phosphate. The phosphate content in the positive electrode of the lithium battery is 2wt% of the active material of the positive electrode. The positive active material is lithium nickel cobalt manganese oxide, layered crystal structure, chemical composition LiNi 1-x-y co x mn y o 2 , where x=0.15, y=0.4. Phosphate is Ba 3 (PO 4 ) 2 Nano powder, the purity is more than 99.9wt%.

[0037] The positive electrode sheet was cut into a disc with a diameter of 12 mm, and the lithium foil was used as the negative electrode to assemble the button battery. The mixed lithium battery electrolyte is selected, the ratio is EC:DEC:DMC (diethyl carbonate: dimethyl carbonate: ethyl methyl carbonate) is 1:1:1, and the electrolyte is 1mol / L LiPF6.

[0038] (1) Charge and discharge the assembled battery for the first time: place it at 4...

Embodiment 2

[0040] Embodiment 2: The lithium battery positive electrode material used in this embodiment is mainly composed of positive electrode active material and phosphate. The phosphate content in the positive electrode of the lithium battery is 1wt% of the active material of the positive electrode. The positive active material is lithium nickel cobalt manganese oxide, layered crystal structure, chemical composition LiNi 1-x-y co x mn y o 2 , where x=0.2, y=0.3. Phosphate is Ba 3 (PO 4 ) 2 Nano powder, the purity is more than 99.9wt%.

[0041] The positive electrode sheet was cut into a disc with a diameter of 12 mm, and the lithium foil was used as the negative electrode to assemble the button battery. The mixed lithium battery electrolyte is selected, the ratio is EC:DEC:DMC (diethyl carbonate: dimethyl carbonate: ethyl methyl carbonate) is 1:1:1, and the electrolyte is 1mol / L LiPF6.

[0042] (1) Assemble the positive electrode of the lithium-ion battery with added lithium...

Embodiment 3

[0044] Embodiment 3: The lithium battery positive electrode material used in this embodiment is mainly composed of positive electrode active material and phosphate. The phosphate content in the positive electrode of the lithium battery is 0.5wt% of the active material of the positive electrode. The positive active material is lithium nickel cobalt manganese oxide, layered crystal structure, chemical composition LiNi 1-x-y co x mn y o 2 , where x=0.3, y=0.2. Phosphate is Ba 3 (PO 4 ) 2 Nano powder, the purity is more than 99.9wt%.

[0045] The positive electrode sheet was cut into a disc with a diameter of 12 mm, and the lithium foil was used as the negative electrode to assemble the button battery. The mixed lithium battery electrolyte is selected, the ratio is EC:DEC:DMC (diethyl carbonate: dimethyl carbonate: ethyl methyl carbonate) is 1:1:1, and the electrolyte is 1mol / L LiPF6.

[0046] (1) Assemble the positive electrode of the lithium-ion battery with added lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com