Method for preparing nano-structured Zn2SnO4 on stainless steel wires

A nanostructure, stainless steel wire technology, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve the problems of unfavorable development of flexible DSSCs, organic polymers are not resistant to high temperature, and metal flakes are unfavorable for light projection, etc. Conversion efficiency, wide application temperature, and the effect of facilitating the transmission of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 0.6mmol of tin tetrachloride pentahydrate, 1.2mmol of zinc acetate dihydrate and 7.2mmol of sodium hydroxide into a solution of 15mL of ethylenediamine and 15mL of water, and stir for 0.5 to 1h by magnetic force;

[0039] (2) Pour the mixture obtained in (1) into a 50ml polytetrafluoroethylene-lined stainless steel autoclave, then put the cleaned stainless steel wire into the autoclave, heat up to 200°C, and react for 24 hours. After cooling with the furnace;

[0040] (3) Take out the stainless steel wire, wash it with distilled water, and then irradiate it with infrared light to achieve the drying effect.

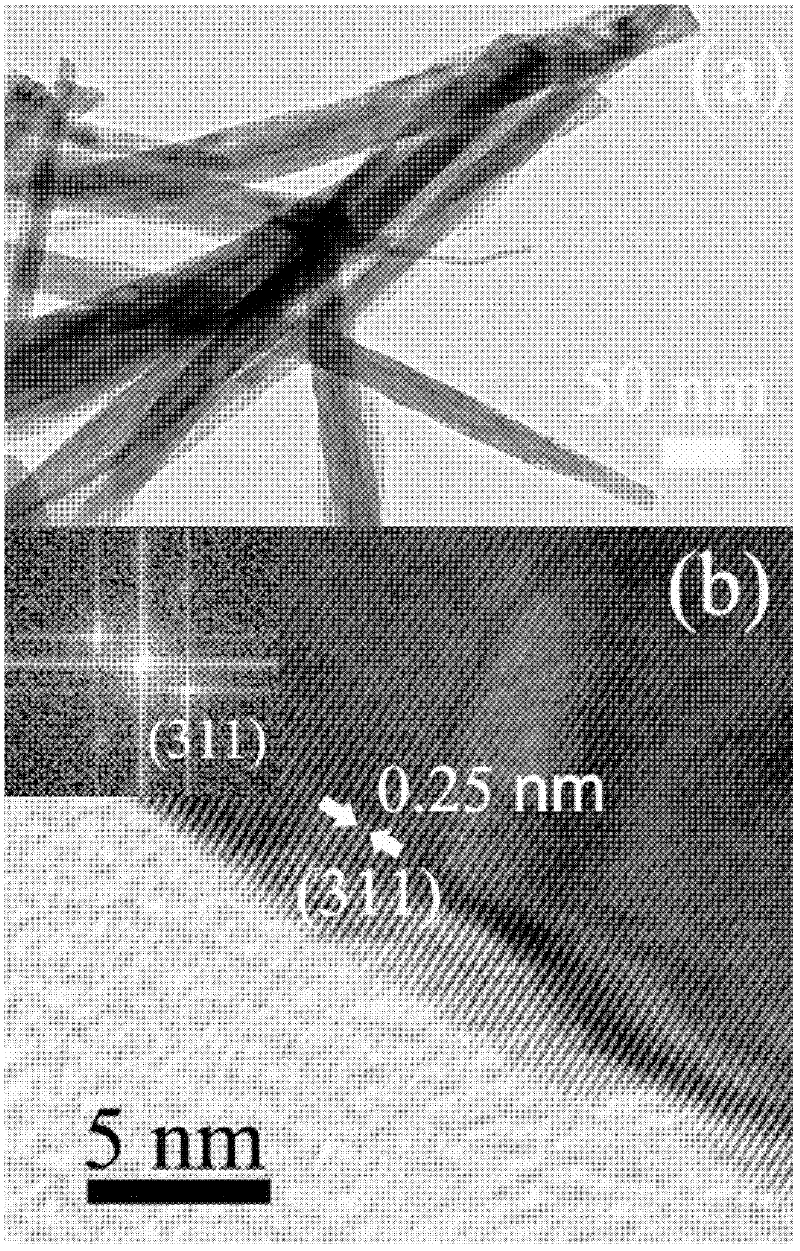

[0041] The products were analyzed by X-ray diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM).

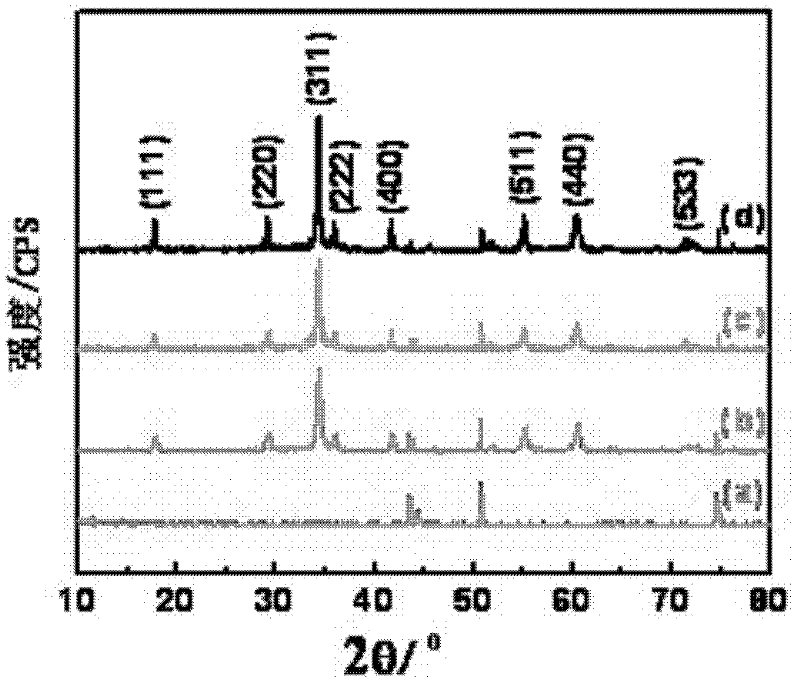

[0042] refer to figure 1 ,in figure 1 Be embodiment 1, the XRD figure of 2 and 3 products, the result shows that the present embodiment 1-3 product is Zn 2 SnO 4 , without any impurities.

[0043] figure 2 It ...

Embodiment 2

[0046]The steps are basically the same as Example 1, except that the solvent is pure water.

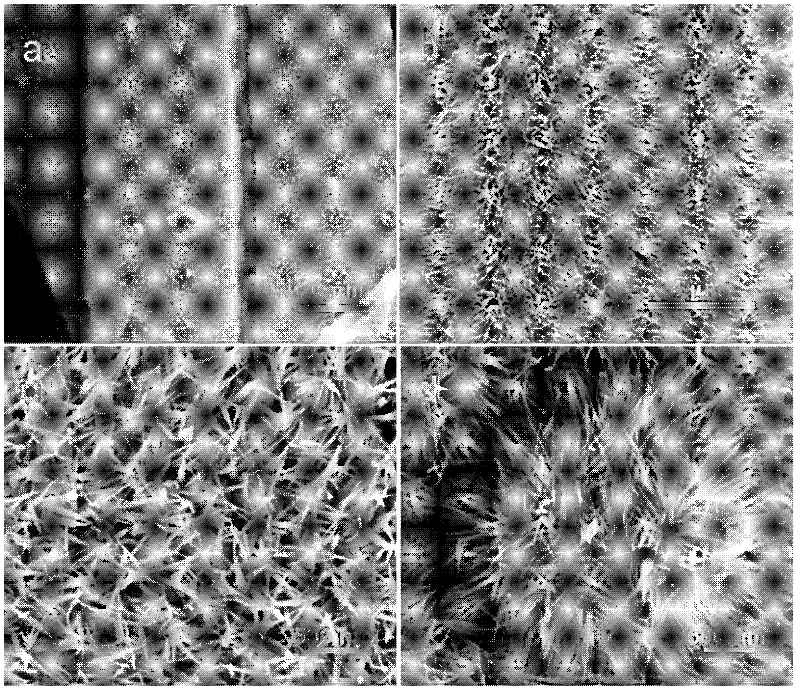

[0047] The morphology of the prepared product is a nanosheet, and its scanning electron microscope picture is as follows: Figure 4 As shown, the side length of the hexagonal sheet is about 300-500nm, the thickness is about 80-100nm, and the hexagonal sheet grows uniformly and densely on the stainless steel mesh.

[0048] Figure 5 It is the TEM figure of embodiment 2 product, Figure 5 (b) High-resolution TEM image of a monolithic nanosheet. It can be seen from the figure that the crystallization is good.

Embodiment 3

[0050] The steps are basically the same as in Example 1, except that the solvent is 10 mL of ethylenediamine and 20 mL of water.

[0051] The morphology of the prepared product is nanoparticles, and its scanning electron microscope picture is as follows: Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com