Display panel and method of manufacturing the same

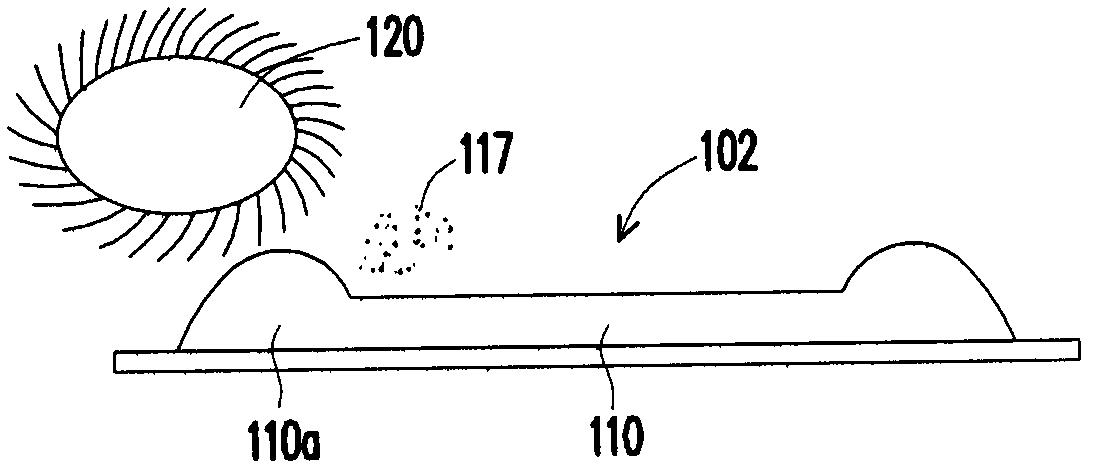

A technology for a display panel and a manufacturing method, applied in nonlinear optics, instruments, optics, etc., capable of solving problems such as debris 117 falling, affecting display quality, and uneven surface of an alignment material layer 110

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

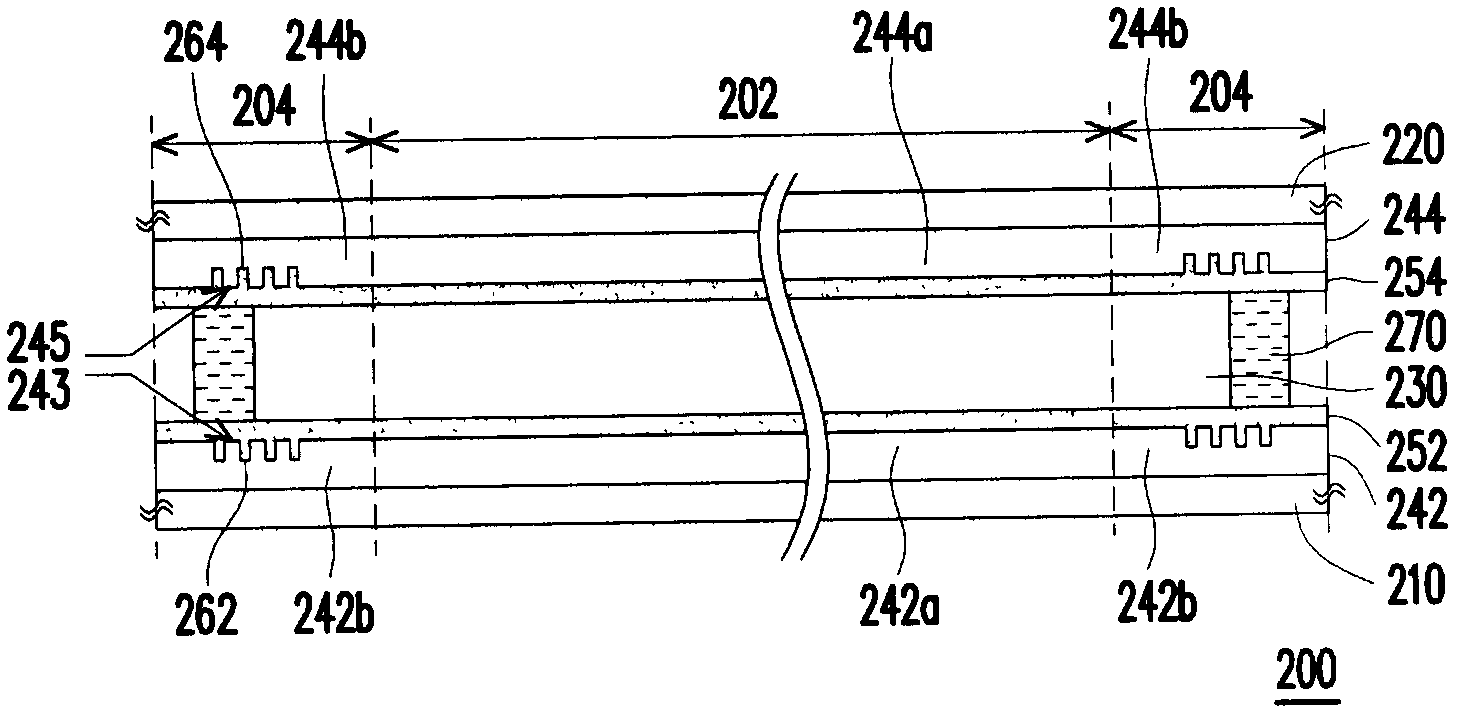

[0063] figure 2 It is a display panel according to an embodiment of the present invention. Such as figure 2 As shown, the display panel 200 includes a first substrate 210 , a second substrate 220 and a display medium 230 located between the first substrate 210 and the second substrate 220 . Here, the display medium 230 is, for example, a liquid crystal material, but the invention is not limited thereto. The first substrate 210 is, for example, an active device array substrate, and correspondingly, the second substrate 220 is, for example, a color filter substrate. In one embodiment, the first substrate 210 is, for example, a color filter substrate, and correspondingly, the second substrate 220 is, for example, an active device array substrate. Of course, in other embodiments, the first substrate 210 may also integrate an active element array substrate (Color Filter on Array, COA) with a color filter film, or an active element array substrate (Black matrix on Array) integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com