Gear-shifting drum interlocking mechanism of automatic gearbox

A technology of automatic transmission and interlocking mechanism, applied in mechanical equipment, transmission control, components with teeth, etc., can solve problems such as easy interference, increase failure rate, increase system failure rate, etc., to reduce The effect of software program volume, improving response time, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

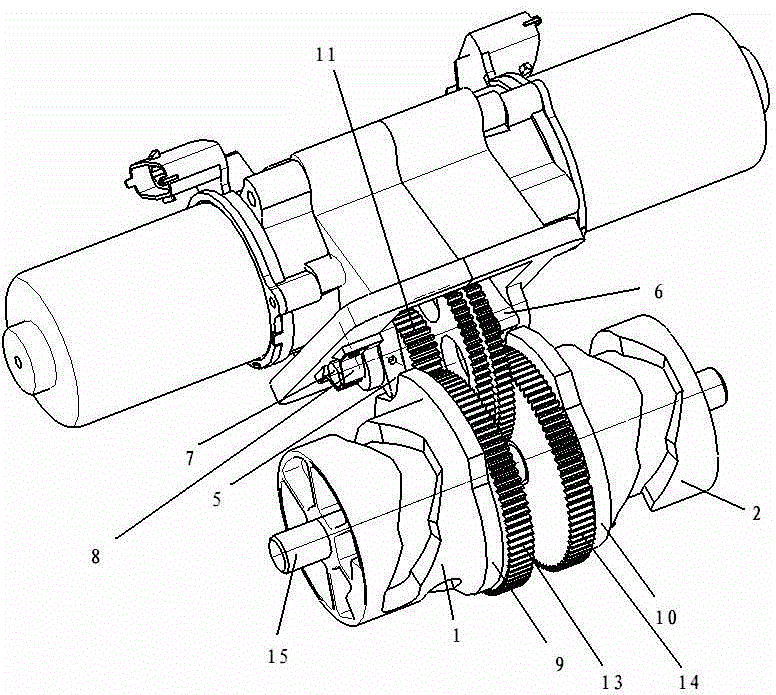

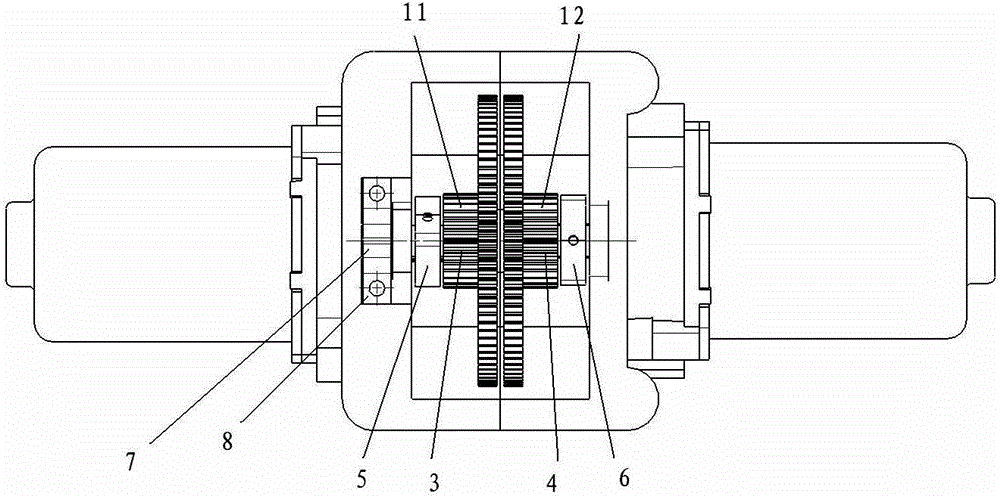

[0017] Such as figure 1 As shown, an automatic transmission shift drum interlock mechanism includes shift drums 1, 2, shift drum gears 13, 14, shift drum shaft 15 and interlock cams 9, 10, and also includes The interlocking camshaft 7 of the gear drum shaft 15 is connected with two main reduction gears 11, 12 on the interlocking camshaft 7, and the main reduction gears 11, 12 are respectively connected with the two gear shifting gears on the shifting drum shaft 15. The drum gears 13 and 14 mesh, and the two main reduction gears 11 and 12 are respectively driven by two independent motors, and the power is transmitted to the shift drum through gear transmission, and the two shift drums 1 and 2 drive four shift forks to generate Shift movement.

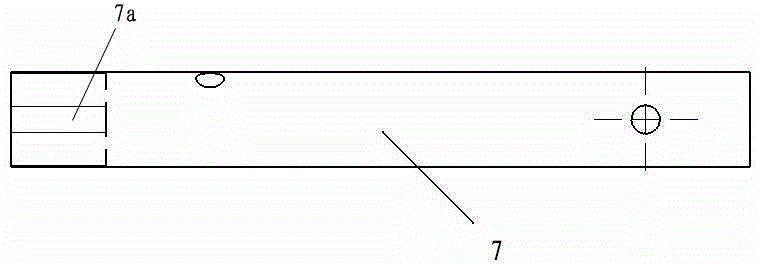

[0018] Such as figure 1 , figure 2 and Image 6 As shown, there are two arc-edge triangular cams 5 and 6 on the interlocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com