Traction drive continuously variable transmission

A technology of continuously variable transmission and traction transmission, applied in transmission devices, fluid transmission devices, belts/chains/gears, etc., can solve the problem of few mechanical continuously variable transmissions, achieve wide transmission range, flexible and convenient control, and simple structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

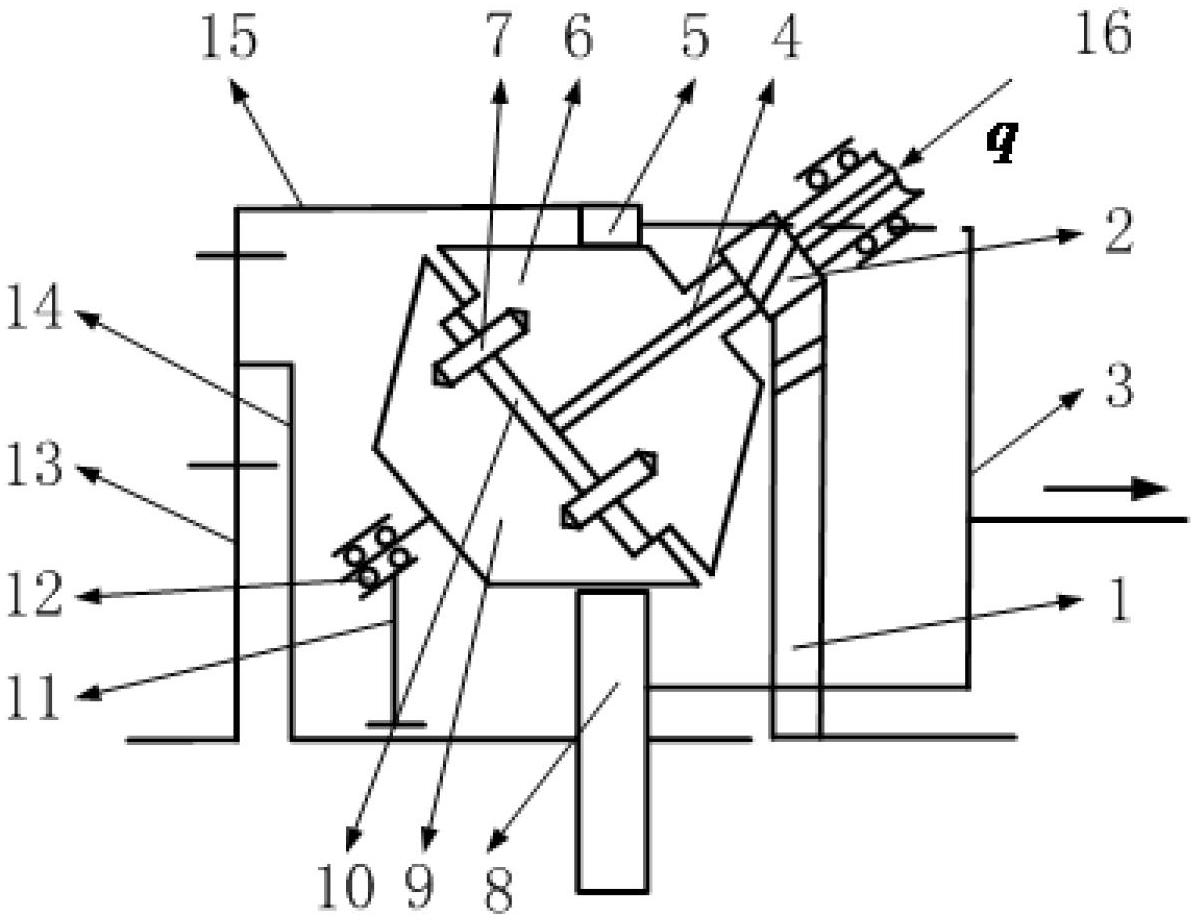

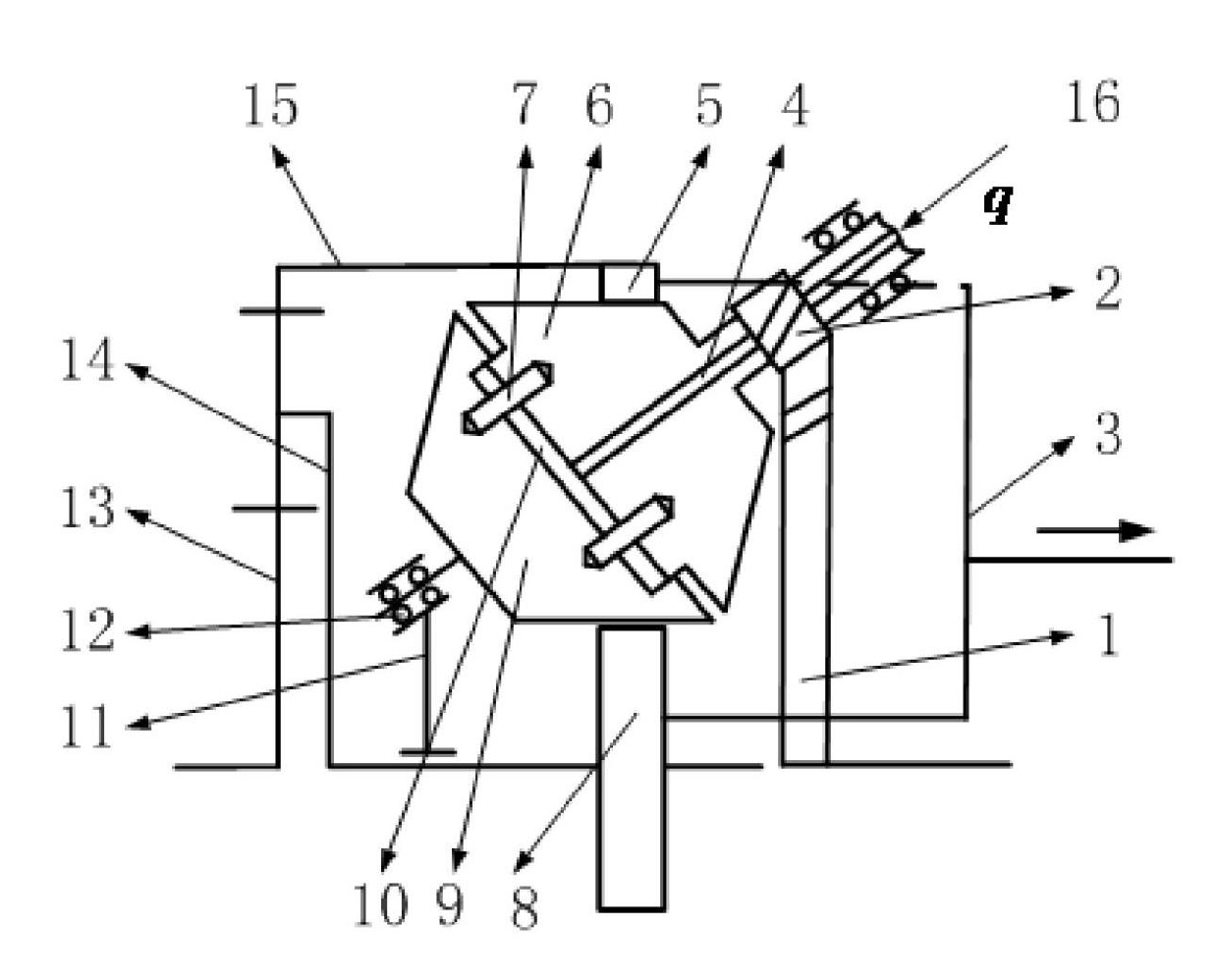

[0015] Such as figure 1 , figure 2 As shown, the technical solution of the present invention is: a traction drive continuously variable transmission, including input bevel gear 1, driven helical gear 2, outer friction wheel 5, outer conical roller 6, transmission pin 7, inner friction wheel 8 , inner tapered roller 9, bearing bracket 11, bearing 12, planetary row and hydraulic system 16;

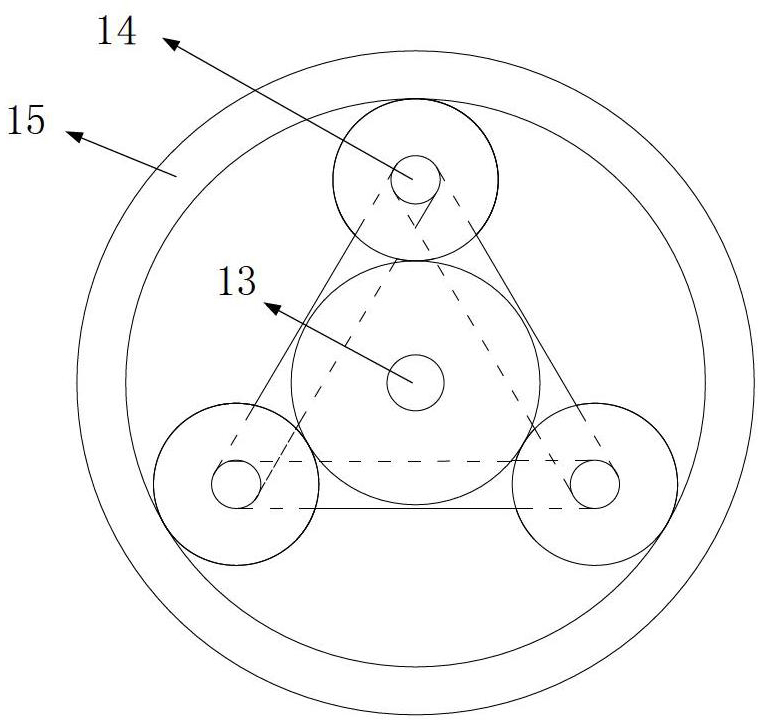

[0016] Wherein, the planet row is made up of ring gear 15, planet carrier 14 and planet row sun gear 13;

[0017] The bottom surface of the inner tapered roller 9 is provided with grooves along its axial direction, and the bottom surface of the outer tapered roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com