Cornice steel skeleton and bracket steel skeleton for large-span big roof of pseudo-classic architecture and construction method of cornice steel skeleton and bracket steel skeleton

An antique building, large-span technology, applied in the direction of architecture, building components, building structures, etc., to achieve the effect of ensuring accuracy and overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

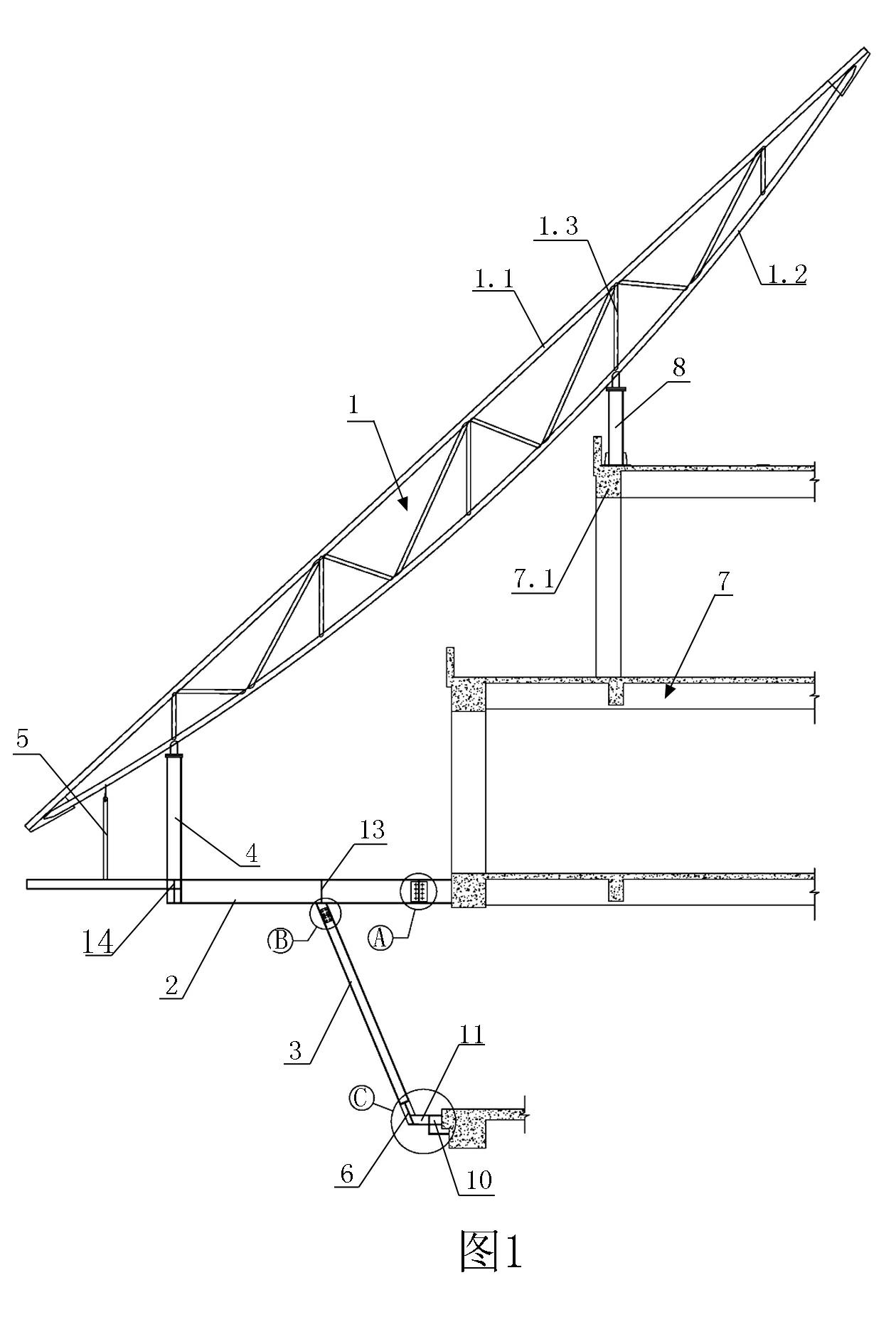

[0039] Examples see Figure 1 to Figure 5As shown, a large-span cornice bucket arch steel skeleton on the large roof of an antique building is obliquely installed on the overhanging part of the main structure 7, including the cornice skeleton and the bucket arch skeleton, and is characterized in that: the cornice skeleton is a pipe truss 1, and the bottom The supporting steel column 4, the lower supporting steel column 5 and the upper supporting column 8 form an inclined roof, and the pipe truss 1 is rigidly connected to the above three. The lower supporting steel column 4 and the lower supporting steel column 5 are supported on On the cantilever beam 2 cantilevered from the top of the main structure, the upper support column 8 is set on the topmost structural beam 7.1 of the main structure 7; Composed of small beams 11, the space between the bucket arch diagonal brace 3 and the bucket arch horizontal beam 6 is vertical, the bucket arch small beam 11 is horizontally arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com