Integral-type vacuum heat insulation and temperature preservation plate

A vacuum insulation, integrated technology, applied in the direction of heat preservation, insulation improvement, climate change adaptation, etc., can solve the problems of affecting the progress and quality of construction projects, heat preservation and energy saving effect, poor surface flatness, easy to generate cold and heat bridges, etc. The effect of energy saving, heat preservation, size specification, and flatness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

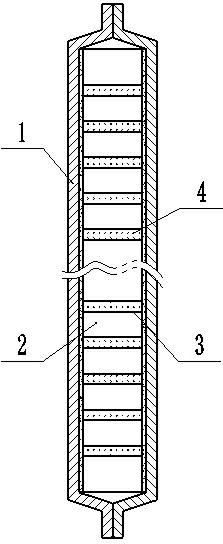

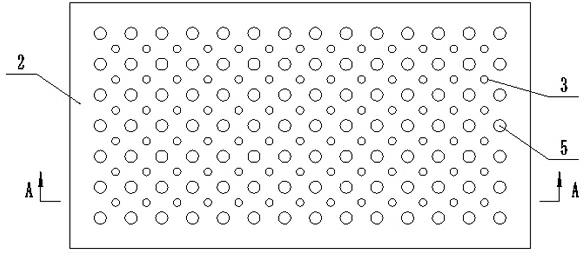

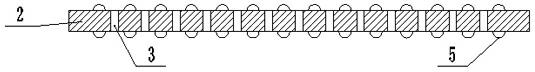

[0012] Such as figure 1 , 2 As shown in and 3, the integral vacuum heat insulation board includes an encapsulation layer 1 and a core material plate 2, the core material plate 2 is located between two layers of encapsulation layers 1, and the surroundings of the two layers of encapsulation layers 1 are fused and connected, and the core material plate A plurality of through holes 3 are evenly arranged on the board surface of 1, and the getter 4 is filled in the through holes, and the two board surfaces of the core material board 2 are coated with adhesive, and the encapsulation layer 1 and the core material board 2 Surfaces are joined together.

[0013] A plurality of hemispherical protrusions 5 in a rectangular array are evenly distributed on the surface of the core board 1 , and the through holes 3 are located in the middle of four adjacent hemispherical protrusions 5 .

[0014] The hemispherical protrusions 5 distributed on the board surface of the core board 2 are 2-4 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com