Ironing board of asphalt paver with downward deformation by being pre-pressed by strut and pull rods

A technology of screed and tie rod, applied in the direction of road, road repair, road, etc., to achieve the effect of wide application range, novel and reasonable design, and improvement of paving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

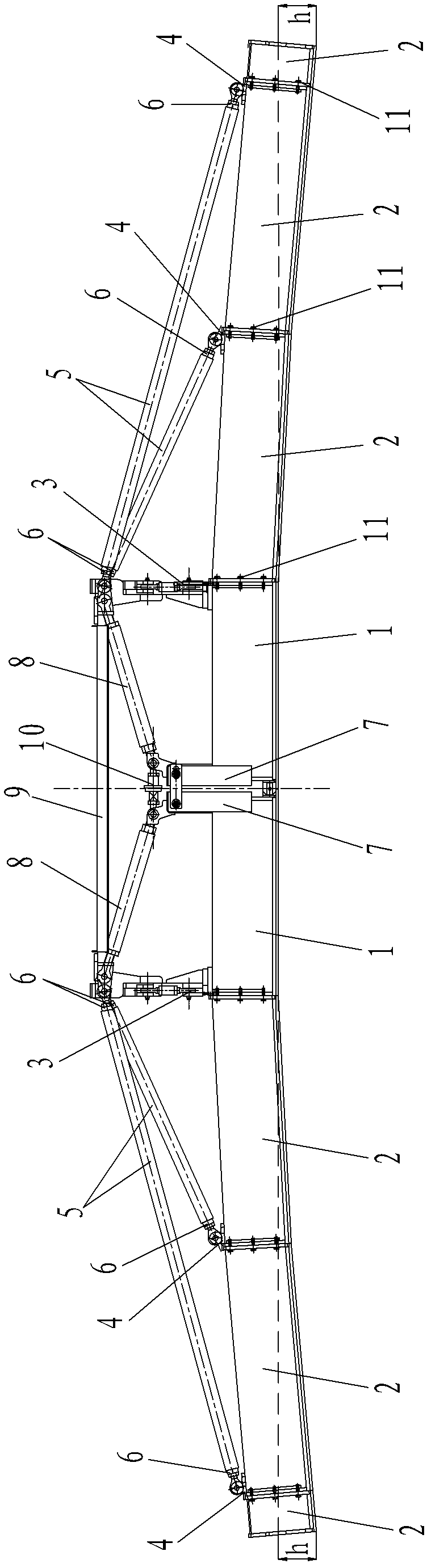

[0022] Such as figure 1 As shown, the present invention includes a mechanically assembled widened screed composed of a basic section screed and a plurality of extended section screeds 2 symmetrically installed on the left and right sides of the basic section screed. Two symmetric single-segment basic screeds 1 are connected together; each single-segment basic screed 1 is provided with a basic screed support 3, and each of the extended screeds 2 is provided with a The extended section screed support 4 is provided with a plurality of bracing rods 5 between the two basic section screed braces 3 and a plurality of the extended section screed braces 4, and one end of the bracing rod 5 is installed in the The screw length adjusting device 6 on the basic section screed bracket 3 is connected to the basic section screed bracket 3, and the other end of the bracing rod 5 passes through the screw length adjusting device 6 installed on the extended section screed bracket 4 Connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com