Automatic leveling paver ironing structure with heating function

A leveling paver, automatic technology, applied in the field of automatic leveling paver ironing structure, can solve the problems of iron wire sagging, uneven road surface, etc., achieve the effect of high reliability, improve the smoothness of paving, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below through specific examples.

[0018] Automatic leveling paver ironing structure with heating function, including ironing plate main body 1, left oil cylinder 2, right oil cylinder 3, middle oil cylinder 4, heating device and leveling device, the left side of ironing plate main body 1 passes through the left force applying part 5 is connected with the left oil cylinder 2, the right side of the main body of the ironing plate 1 is connected with the right oil cylinder 3 through the right force applying part 6, and the middle part of the ironing plate main body 1 is connected with the middle oil cylinder 4 through the force applying part 7;

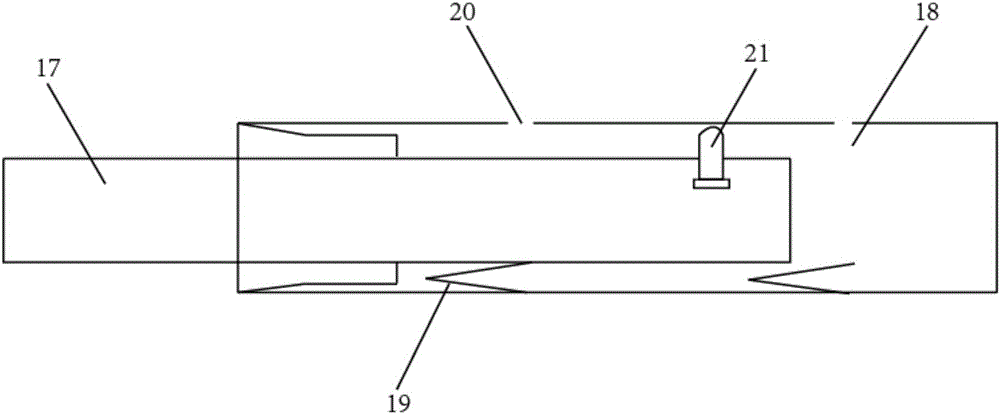

[0019] The heating device includes an air storage tank, an air supply pipeline 13, an air injection part 14, an ignition part 15 and a temperature sensor 16. The air storage tank is arranged on the inner side of the ironing plate main body 1, and the air sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com