Epoxy conductive resin applicable to binding of LED (light-emitting diode) chips, and preparation method thereof

A technology of epoxy conductive adhesive and LED chip, applied in epoxy resin adhesive, conductive adhesive, adhesive and other directions, can solve the problems of large waste, unsatisfactory performance of domestic products, poor electrical conductivity, etc., and achieve high thermal conductivity, Small sticky crystal residence time, good heat resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

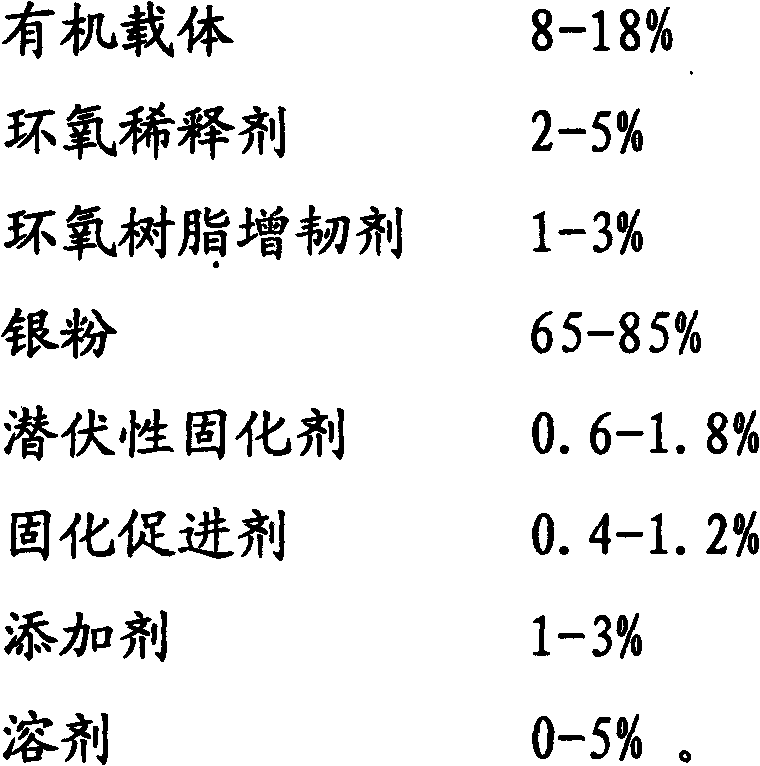

Method used

Image

Examples

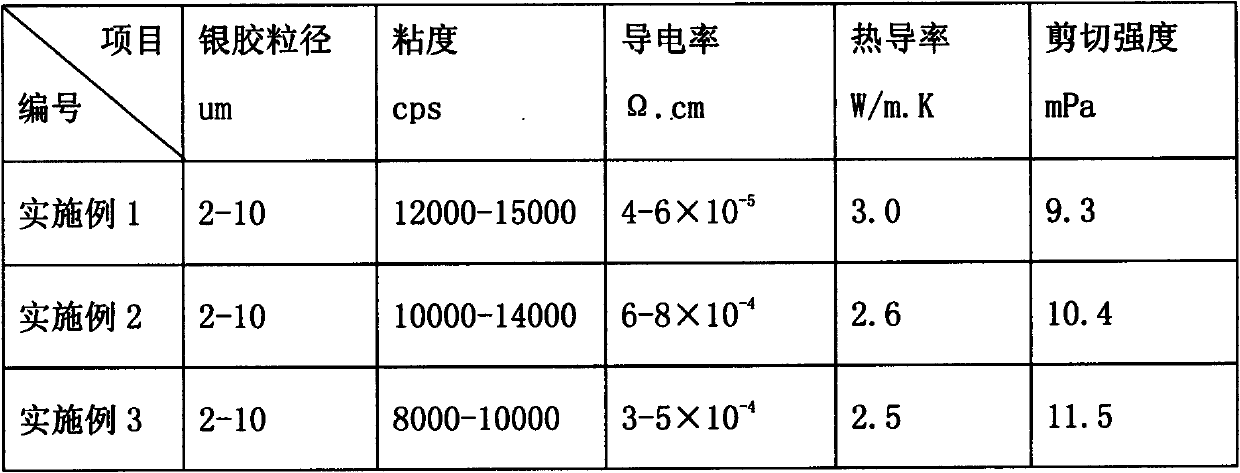

Embodiment 1

[0029] (a) 11% of organic vehicle (7% of bisphenol A epoxy resin and 4% of modified bisphenol F epoxy resin); 3% of epoxy diluent C12-C14 alkyl glycidyl ether, in parts by mass Add in sequence, stir evenly, vacuumize and defoam for 15-20 minutes;

[0030] (b) Then add latent curing agent (micronized dicyandiamide Dyhard 100S: 0.9%, curing accelerator micronized feuron Dyhard UR 300: 0.6%), epoxy resin toughener Dow DER 736: 3%, additives (polymer dispersant Suosperse3263: 0.5%, antioxidant 1076: 0.5% and coupling agent KH-550: 0.5%) 1.5%, after mixing uniformly in the reactor, vacuumize 30-60min, the vacuum degree is -0.1MPa;

[0031] (c) Add 80% silver powder (flaky silver powder, 3-7μm 60% and spherical silver powder 0.1-0.5μm 20%) into the three-dimensional stirring tank, stir well and put it into a three-roller machine to grind 1-3 times to get the product Taste.

Embodiment 2

[0033] (a) 14% of organic vehicle (9% of bisphenol A epoxy resin and 5% of liquid novolac epoxy resin); 4% of epoxy diluent (2% of hexanediol glycidyl ether and 2% of resorcinol glycidyl Ether 2%); add in parts by mass, stir evenly, vacuumize and defoam for 15-20 minutes;

[0034] (b) Then add a latent curing agent (hexafluoroantimonate type heat-initiated cationic epoxy resin latent curing agent ICAM-8409: 1.3%, curing accelerator 2-ethyl 4-methylimidazole) in parts by mass 2E4MI: 0.7%), epoxy resin toughening agent, polyurethane modified epoxy resin PLM-3515 produced by Zhuzhou Shilin: 3%, additives 2% (0.5% coupling agent kh-560: 0.5% special silicone degassing Agent Nofol: 4559, antioxidant BHT: 0.5% and 0.5% polyurethane dispersant Suosperse 3263), after mixing evenly in the reactor, vacuumize for 30-60min, and the vacuum degree is -0.1MPa;

[0035] (c) Add flake silver powder 3-7μm 75% into a three-dimensional stirring tank, stir well and put it into a three-roll machin...

Embodiment 3

[0037] (a) 15% organic vehicle (composed of 10% bisphenol A epoxy resin and 6% modified bisphenol A / F epoxy resin), 5% epoxy diluent (trimethylolpropane triglycidyl ether 3 % and diglycidyl ether 2%), add in parts by mass, stir evenly, vacuumize and defoam for 15-20 minutes;

[0038] (b) Then add latent curing agent (micronized dicyandiamide Dyhard 100S: 1.5%, curing accelerator (micronized Feuron Dyhard UR: 300) 1.0%, epoxy resin toughening agent Tao by mass parts respectively DER 732: 3%, additives (polymer dispersant Suosperse3263: 0.5%, antioxidant-618: 0.5% and coupling agent KH-550: 0.5%) 1.5%, after mixing uniformly in the reactor, Vacuumize for 30-60min, the vacuum degree is -0.1MPa;

[0039] (c) Add 70% of silver powder (flaky silver powder 3-7μm 55% and spherical silver powder 0.1-0.5μm 15%) into the three-dimensional stirred tank, add 3% mixed acid methyl ester (MBE) solvent during the stirring process, and stir well Put it into a three-roll machine and grind it f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap