Method for preparing poly-m-phenylenediamine through oxidation of composite oxidation system

A poly-m-phenylenediamine and composite oxidation technology, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem that the degree of oxidation of synthetic products is difficult to effectively adjust, affecting purification processes, and affecting adsorption. performance and other issues, to achieve the effect of reducing secondary pollution and post-treatment detoxification costs, reducing process costs and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

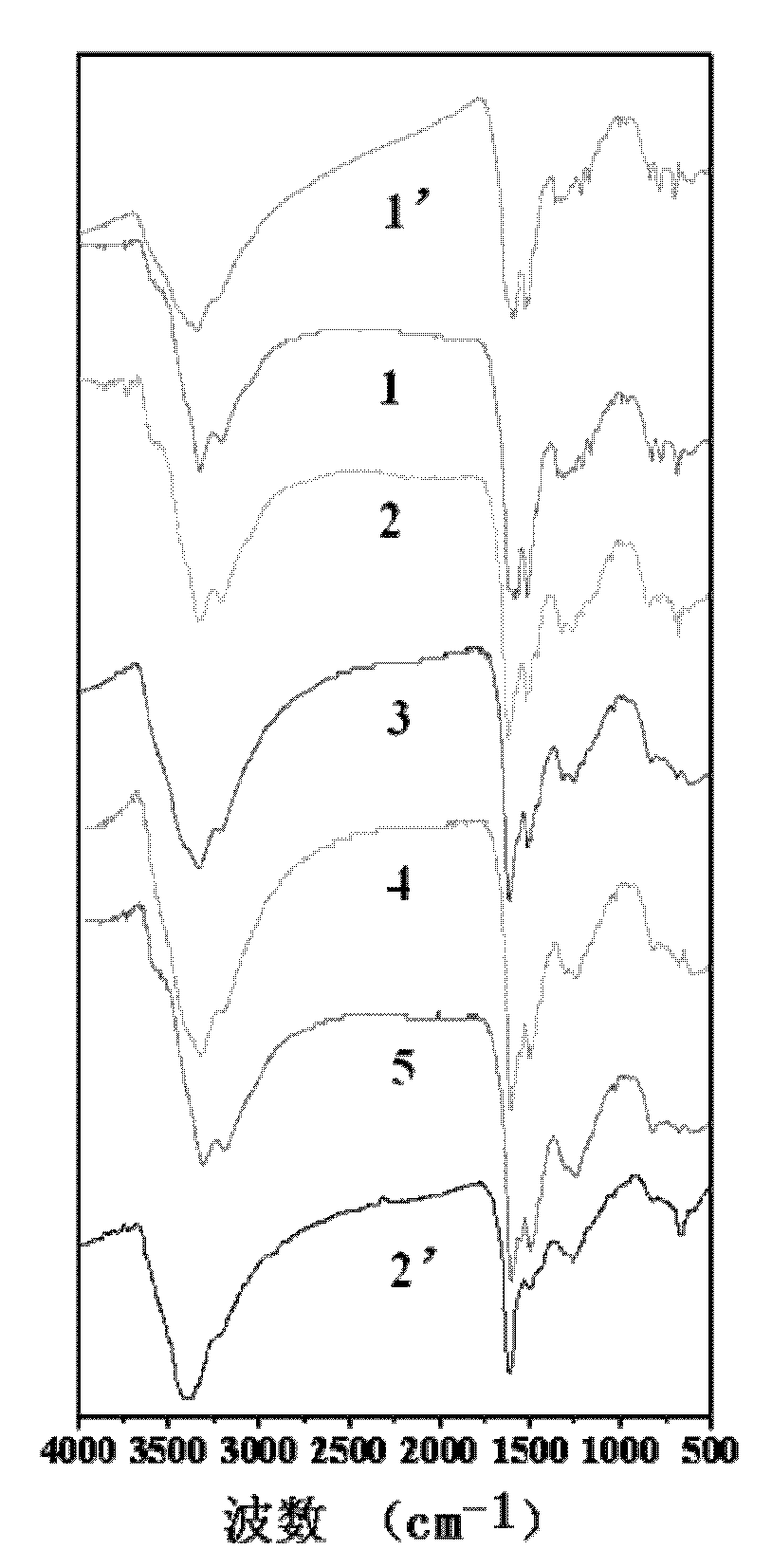

Embodiment 1

[0020] Weigh 10g (0.0925mol) of m-phenylenediamine and dissolve it in 150mL of distilled water, add it into a 500mL four-necked flask, place the four-necked flask in a 45°C water bath and stir for 20min to mix the monomer solution evenly, and raise the temperature of the monomer solution to 45°C. Weigh 2.10g (0.0093mol) ammonium persulfate and dissolve it in 5.5mL distilled water, weigh 0.0233g ferrous sulfate heptahydrate and dissolve it in 84.6mL distilled water, measure 8.6mL 30% (0.0833mol) H 2 o 2 Dissolve in 34.4mL distilled water. The ammonium persulfate aqueous solution was added dropwise into the four-necked flask with a peristaltic pump, and the dropping rate was controlled at 3 mL min -1 After adding the ammonium persulfate solution in about 2 minutes, immediately pour in the ferrous sulfate aqueous solution, and then gradually add the hydrogen peroxide aqueous solution to the four-necked flask after keeping the temperature for five minutes, and the dropping rate ...

Embodiment 2

[0022] Weigh 10g (0.0925mol) of m-phenylenediamine and dissolve it in 150mL of distilled water, add it into a 500mL four-necked flask, place the four-necked flask in a 45°C water bath, stir for 20min, mix the monomer solution evenly, and make the temperature of the monomer solution Warm to 45°C. Weigh 4.20g (0.0185mol) ammonium persulfate and dissolve in 11.0mL distilled water, weigh 0.0207g ferrous sulfate heptahydrate and dissolve in 75.3ml distilled water, measure 7.6mL 30% (0.0741mol) H 2 o 2 Dissolve in 30.4mL distilled water. All the other steps are the same as in Example 1.

Embodiment 3

[0024] Weigh 10g (0.0925mol) of m-phenylenediamine and dissolve it in 150mL of distilled water, add it into a 500mL four-necked flask, place the four-necked flask in a 45°C water bath, stir for 20min, mix the monomer solution evenly, and make the temperature of the monomer solution Warm to 45°C. Weigh 6.30g (0.0278mol) ammonium persulfate and dissolve it in 16.5mL distilled water, weigh 0.0181g ferrous sulfate heptahydrate and dissolve it in 65.9mL distilled water, measure 6.6mL 30% (0.0648mol) H 2 o 2 Dissolve in 26.6mL distilled water. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com