Cable inlet wire winding drum device of roll changing trolley

A technology for cable entry and roller changing trolley, applied in the field of roller changing trolley, can solve the problems of easy damage, collapse and deformation of the reel cable, inconvenient assembly, etc.

Active Publication Date: 2012-08-15

CHONGQING IRON & STEEL CO LTD

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the cable inlet reel device, because the power components such as the brush mechanism inside the base are easily damaged, they often need to be replaced, and the reel device needs to be disassembled during replacement. The defect of inconvenient assembly, at the same time, the cable at the cable inlet is easily damaged, and at the same time, the reel is easily collapsed and deformed by the cable from the cable inlet, resulting in damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

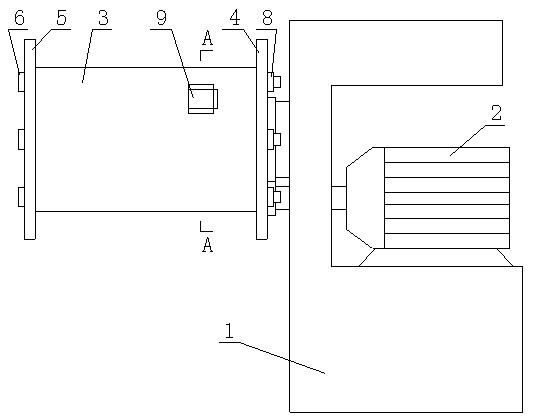

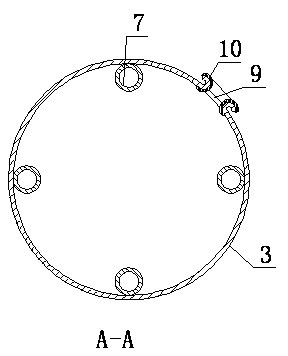

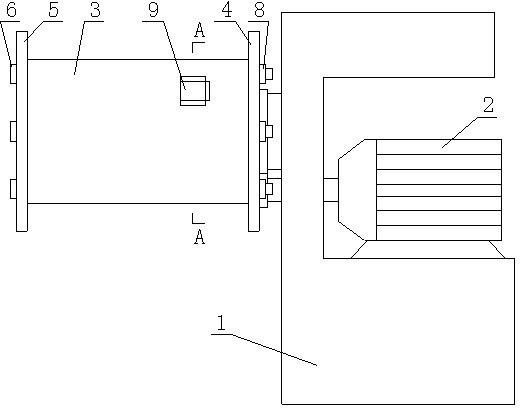

The invention discloses a cable inlet wire winding drum device of a roll changing trolley, comprising a base, wherein the base is provided with a motor and a winding drum device, the winding drum device comprises an iron winding drum, an inner end plate, an outer end plate and a plurality of connecting bolts, the inner wall of the winding drum is welded and fixed with a plurality of steel pipes which are uniformly arranged, the connecting bolts sequentially pass through the outer end plate, the steel pipes in the winding drum and the inner end plate and are fastened by nuts, the nuts are connected and the fixed on the inner side of the inner end plate, the motor is connected with the winding drum device by a transmission mechanism and can drive the winding drum device to rotate, the winding drum is also provided with a wire inlet port, the wire inlet port is rectangular, two sides (arranged at the circumference of the winding drum) of the wire inlet port and one side (arranged in the direction of the inner end plate) of the wire inlet port form extending section which turn and roll outwards, and the surface of each extending section is provided with a rubber layer. The winding drum device disclosed by the invention can conveniently wind and release a wire for travelling of the roll changing trolley and also has the advantages of being simple in structure, convenient, rapid and labour-saving for dismounting, good in cable and winding drum protective effect and long in service life.

Description

technical field [0001] The invention relates to a roll changing trolley used for changing work rolls in a rolling mill, in particular to a cable inlet reel device of the roll changing trolley. Background technique In rolling mills, steel sheets are rolled into shape using rolling mills. Among them, the rack roll is the core component of the rolling mill. Due to the harsh working environment of the rack rolls, long-term work in the environment of high temperature of about 1100°C and high-pressure dephosphorization water of 16MPa, the high temperature and water vapor erosion can easily lead to damage to the rack rolls, especially the bearings. At the same time, during production, the head of the strip steel will frequently hit the rack rollers, causing the bearings to be subjected to radial impact loads, resulting in a high frequency of failures. It often needs to be removed and replaced for maintenance. Because the overall weight of the rack rollers is very large, it ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H75/38B65H75/44

Inventor 周健谭国想陈汉渝曹家宇雷坤王波

Owner CHONGQING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com