Combined type module ship and module connecting way thereof

A combined and connecting plate technology, applied in the field of ships, can solve problems such as prolonging construction time, reducing construction costs, complex shapes, etc., and achieve the effects of improving coordinated construction, shortening construction period, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

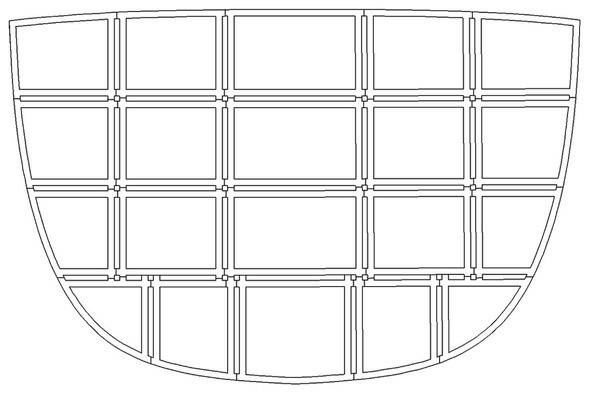

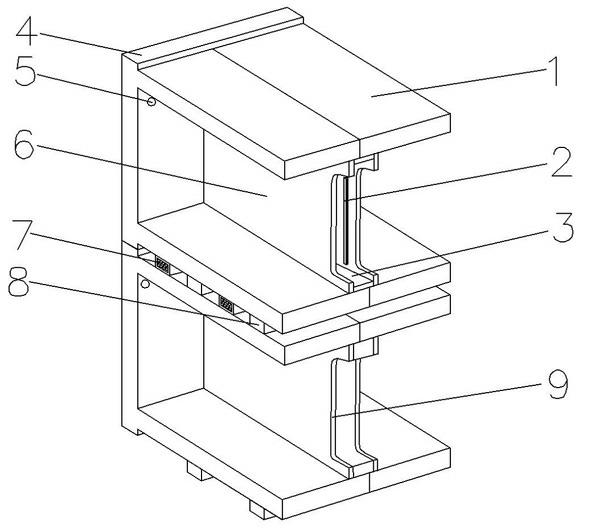

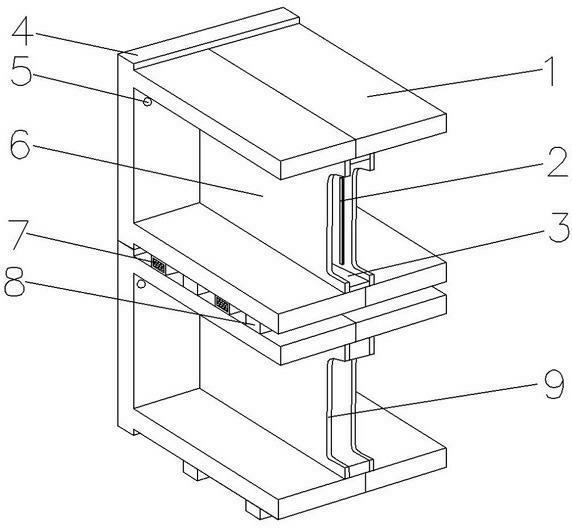

[0022] Such as figure 1 As shown, a combined modular ship provided by the present invention is composed of several hull modules 1 divided according to the structural characteristics of the ship, and connecting plates 4 protruding from the edges of the hull modules 1 to connect adjacent hull modules 1 .

[0023] Such as figure 2 As shown, in the closed space enclosed by the bulkhead 6 and the connecting plate 4 of the hull module 1, at least one outfitting module 7 is provided with electrical and electronic equipment outfitting pieces inside. In this way, the ship outfitting can be built while the hull is being built, and after the hull is completed, only the outfitting needs to be fixed in place to realize the simultaneous progress of the hull and outfitting.

[0024] At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com