Method for treating waste gas containing spontaneously-combustive gas

A technology for waste gas treatment and spontaneous combustion, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve the problem of high equipment cost, avoid energy consumption, improve treatment efficiency, and simplify treatment equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments and accompanying drawings.

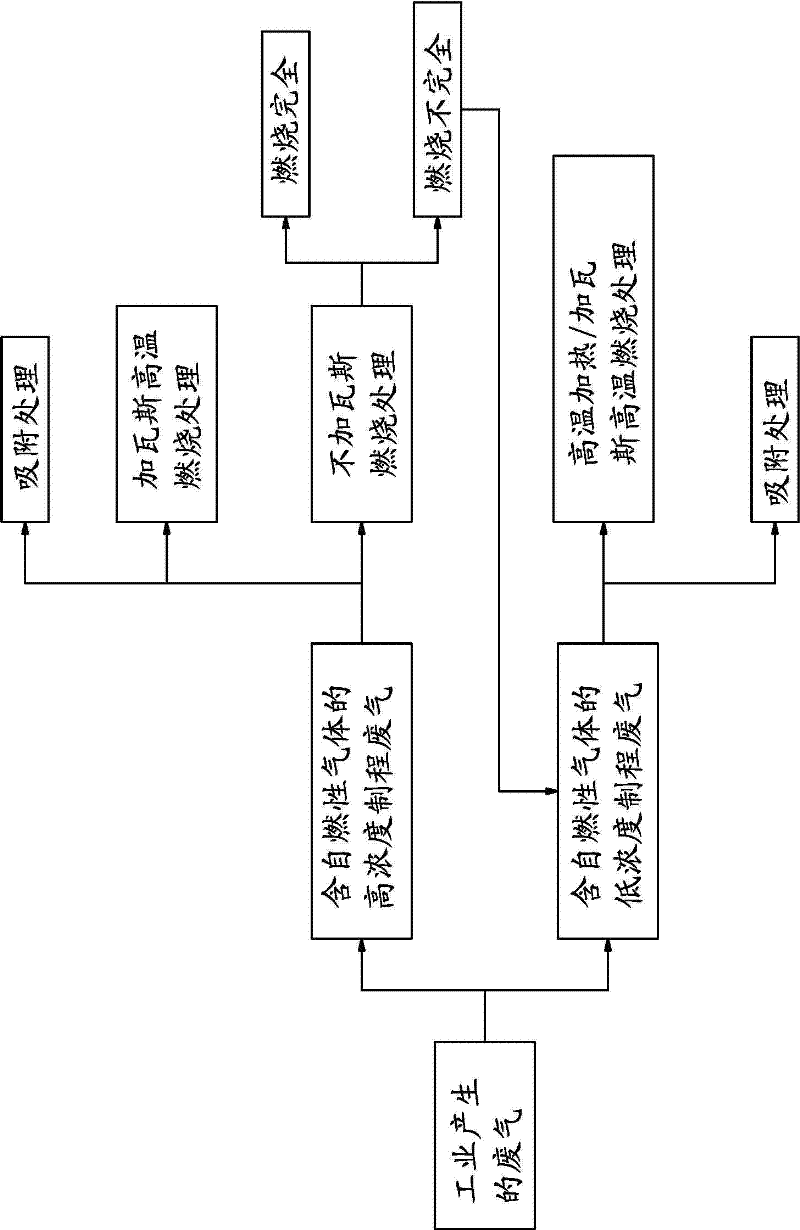

[0020] see figure 1 , which is a schematic diagram of a prior art waste gas treatment method containing pyrophoric gas. In the figure, industrial waste gas includes process waste gas containing high concentration of pyrophoric gas and process waste gas containing low concentration of pyrophoric gas. The process waste gas containing high concentration of pyrophoric gas can be burned without adding gas in the existing technology If the combustion is incomplete, process waste gas containing low-concentration self-igniting gas will be formed, and then treated by high-temperature heating oxidation or high-temperature combustion oxidation; process waste gas containing high-concentration self-igniting gas can also be directly oxidized by high-temperature heating or It is processed by high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com