Production method of low-molecular-weight nutritional protein powder

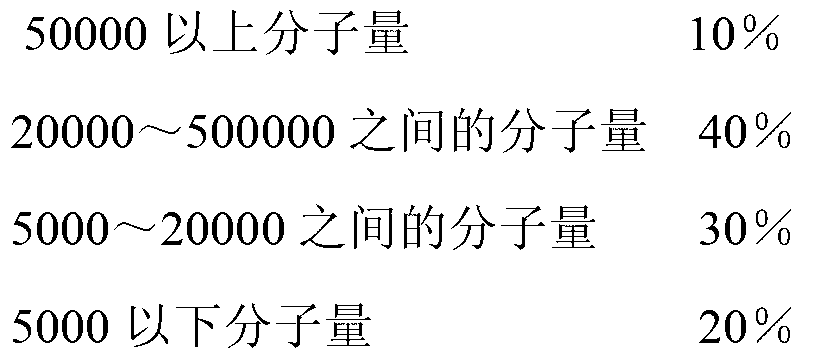

A nutritional protein powder and production method technology, applied in the field of health care products, can solve the problems of difficult dispersion, unsatisfactory absorption effect, high proportion of large molecular weight protein, etc., and achieve the effect of easy dispersion, small molecular weight and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. Take 0.5kg soybean protein powder and 0.5kg whey protein powder and mix them evenly;

[0026] B. Add 20kg of water at 80°C, and stir with a high-speed mixer for 20 minutes to form a uniform suspension without agglomeration;

[0027] C. Filtrate through a 5000 Dalton filter membrane while hot at a temperature not lower than 60°C, using a pressure of 0.4-0.6 MPa to obtain about 16 liters of filtrate A;

[0028] D. Filter the filtrate A through a 500 Dalton filter membrane to separate out small molecular substances, moisture, salt, etc., and the obtained filtrate B is about 1 / 4 of the filtrate A;

[0029] E. Spray-dry the filtrate B, select the inlet air temperature as 90°C, and the eruption volume as 3-5 liters / minute;

[0030] F, add the lecithin of powder weight 1% that obtains after spray drying, mix evenly;

[0031] G, bagging or canning.

[0032] In the protein powder prepared by the method of Example 1, the molecular weight below 5000 accounts for 95%, and amo...

Embodiment 2

[0038] A. Take 0.4kg soybean protein powder and 0.8kg whey protein powder and mix them evenly;

[0039] B. Add 22kg of water at 85°C, and stir with a high-speed mixer for 40 minutes to form a uniform suspension without agglomeration;

[0040] C. Filtrate through a 5000 Dalton filter membrane while hot at a temperature not lower than 60°C, using a pressure of 0.4-0.6 MPa to obtain about 16 liters of filtrate A;

[0041] D. Filter the filtrate A through a 500 Dalton filter membrane to separate out small molecular substances, moisture, salt, etc., and the obtained filtrate B is about 1 / 4 of the filtrate A;

[0042] E. Spray-dry the filtrate B, select the inlet air temperature as 90°C, and the eruption volume as 3-5 liters / minute;

[0043] F, add lecithin about 1.2% of the powder weight obtained after spray drying, and mix evenly;

[0044] G, bagging or canning.

[0045] In the protein powder prepared according to the method in Example 2, the molecular weight below 5000 account...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com