Optimization control method for multi-procedure conveyor belt feeding processing station system with flexible sites

A system optimization and conveyor belt technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of limited communication ability or perception ability of the site, the number of processing sites, the increase of the number of processes, and the incoordination between processes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

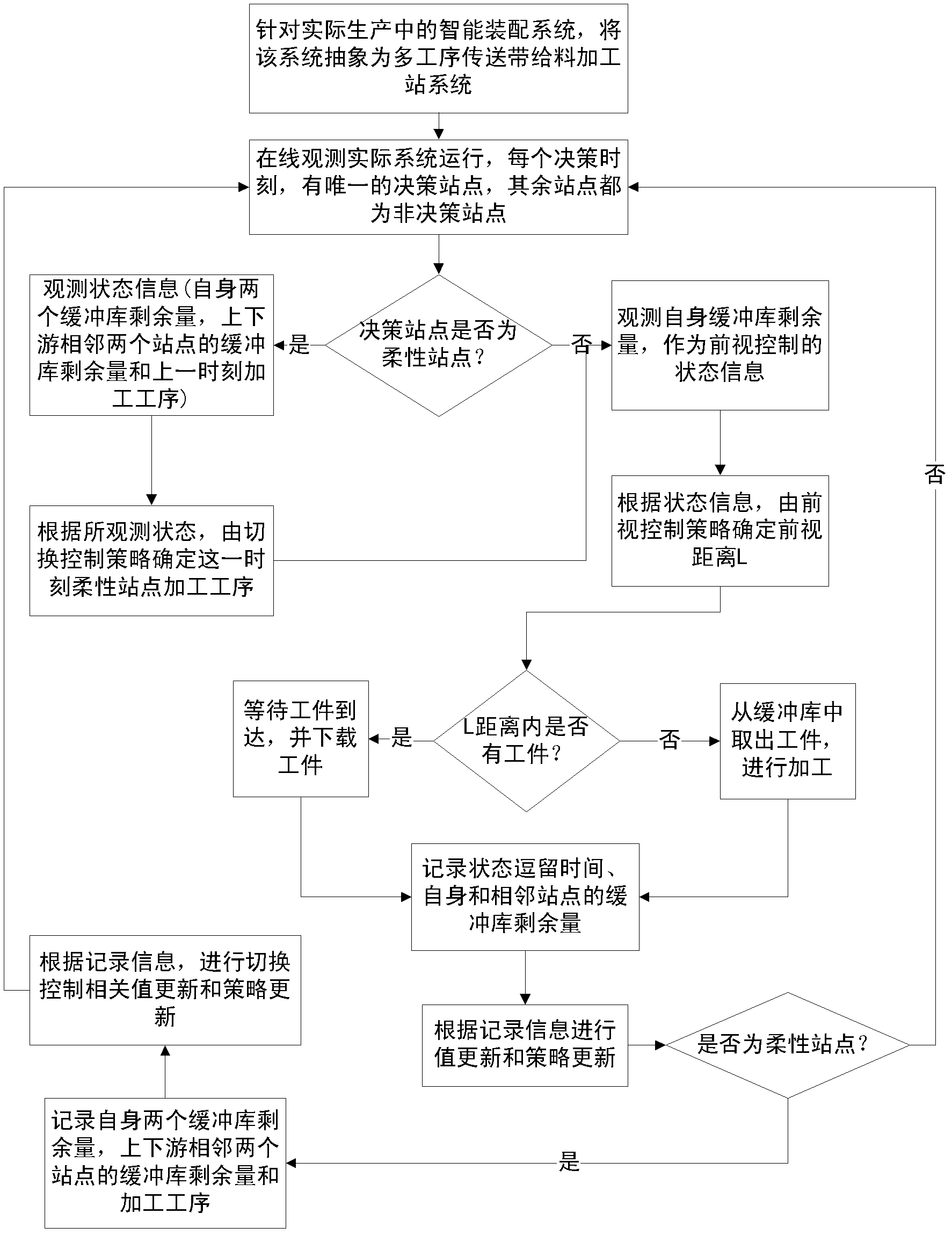

[0040] see figure 1 , figure 2 In the embodiment, the multi-process conveyor belt material processing station system with a flexible station includes a conveyor belt 1, and multiple processes are arranged along both sides of the conveyor belt 1. Each process has its own general station 4, and the adjacent upstream process 2 and downstream There is a flexible station 5 between the process 3, and the flexible station 5 can be controlled to switch between the upstream process 2 and the downstream process 3; the general station 4 is equipped with a buffer store 7 for this process, and is configured to detect upstream workpieces on the conveyor belt General site sensors for position information; adjacent upstream process buffers 8 and adjacent downstream process buffers 9 are respectively configured in the flexible site 5, and flexible site sensors for detecting the position information of the upstream workpiece on the conveyor belt are configured;

[0041] The work tasks of gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com