Mortar box stirring-shaft sealing device for shield equipment

The technology of mixing shaft and mortar is applied in the field of mortar box, which can solve the problems of easy leakage or leakage, difficult repair work, poor sealing effect, etc., and achieves the effects of long service life, simple structure and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

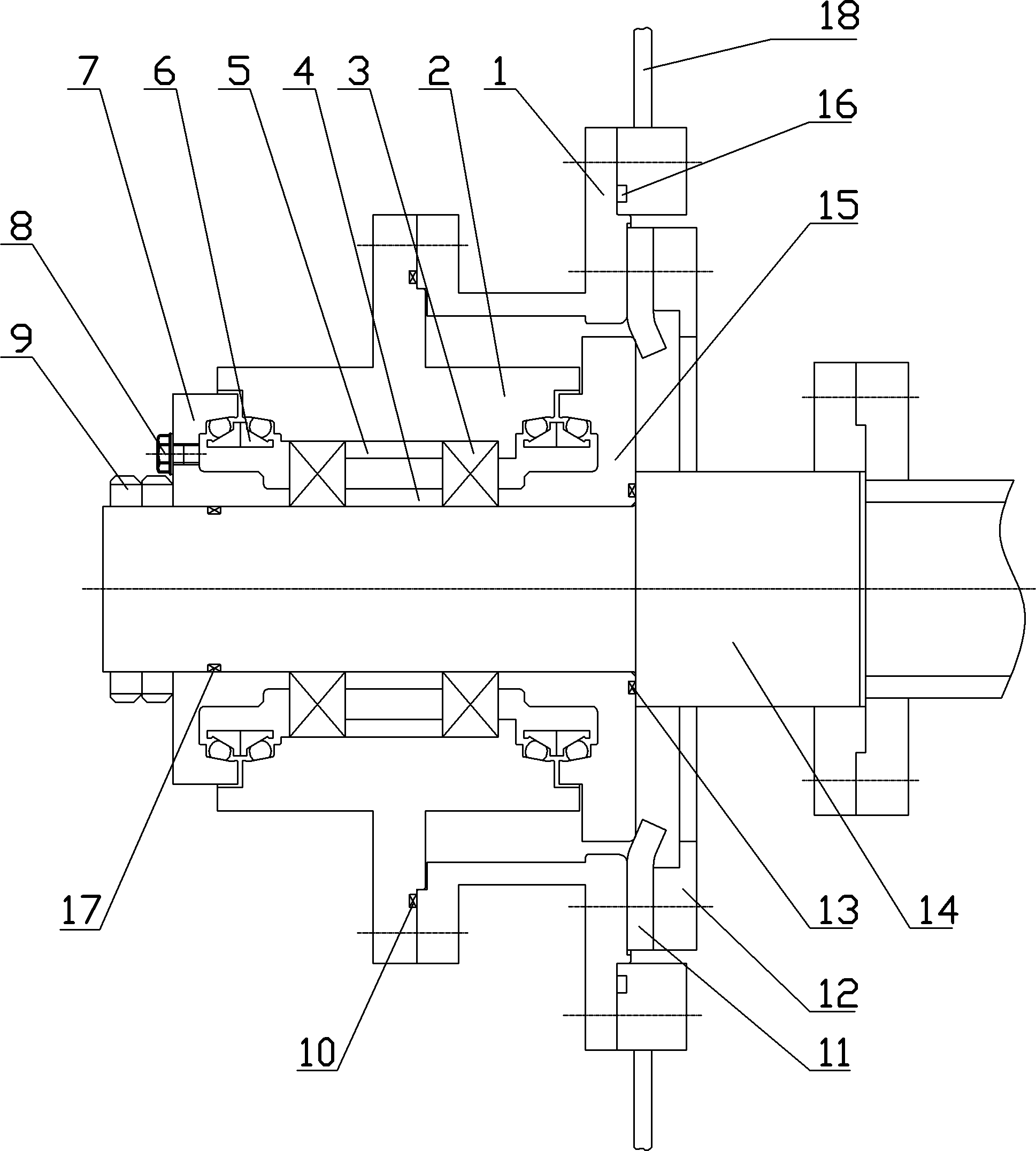

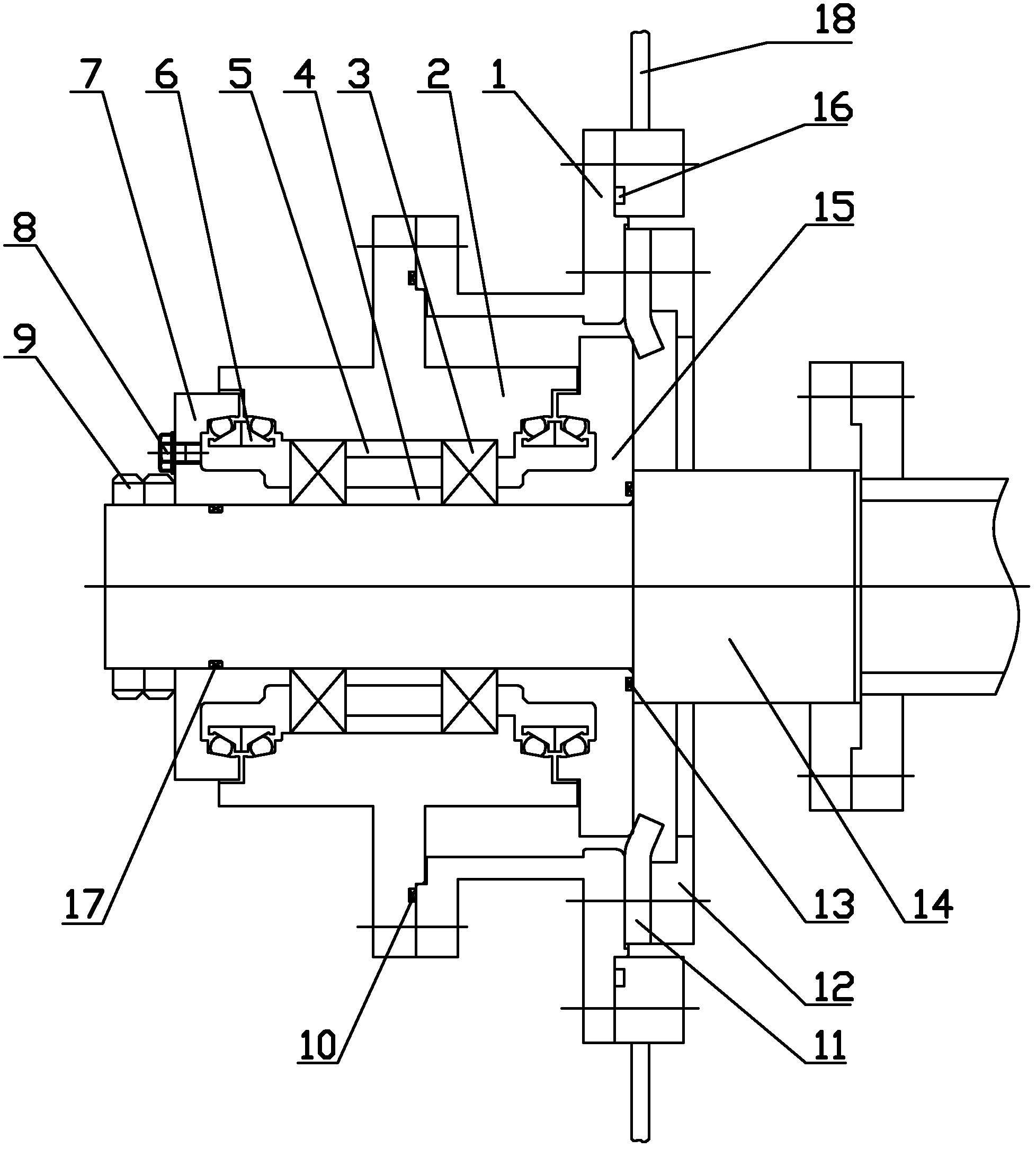

[0014] Such as figure 1 , figure 2 As shown, a mortar box mixing shaft sealing device for shield equipment is composed of a bracket 1, a compression mechanism, a support mechanism and a sealing assembly. The compression mechanism includes a compression device I 7 and a compression device II15, and the compression device I 7 is provided with screw plug 8. The sealing assembly includes corner seal 11, corner seal gland 12, floating seal 6, O-ring I 10, O-ring II 13, O-ring III 16 and O-ring IV 17, and corner seal 11 is made of nitrile rubber (NBR), the corner seal belongs to the end face seal, which generates deformation through axial compression, forms a seal, and prevents the mortar from seeping out; the floating seal is a special form of mechanical seal, also known as the mechanical end face seal. Composed of ground metal seal ring and O-ring seal, it has super sealing performance under harsh working conditions such as sediment, water vapor, etc., has the characteristics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com