Drilling liner cementing rubber plug composite colliding device

A liner cementing and rubber plug technology, which is used in wellbore/well components, earthwork drilling, sealing/packing, etc. The effect of high bearing pressure, reliable fixation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

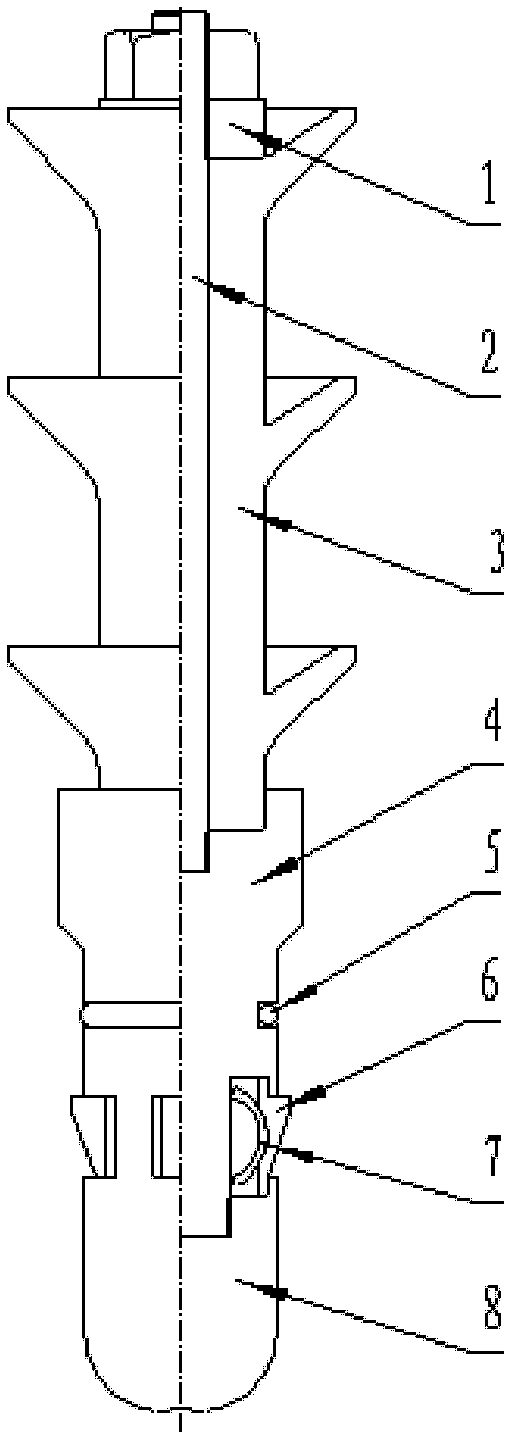

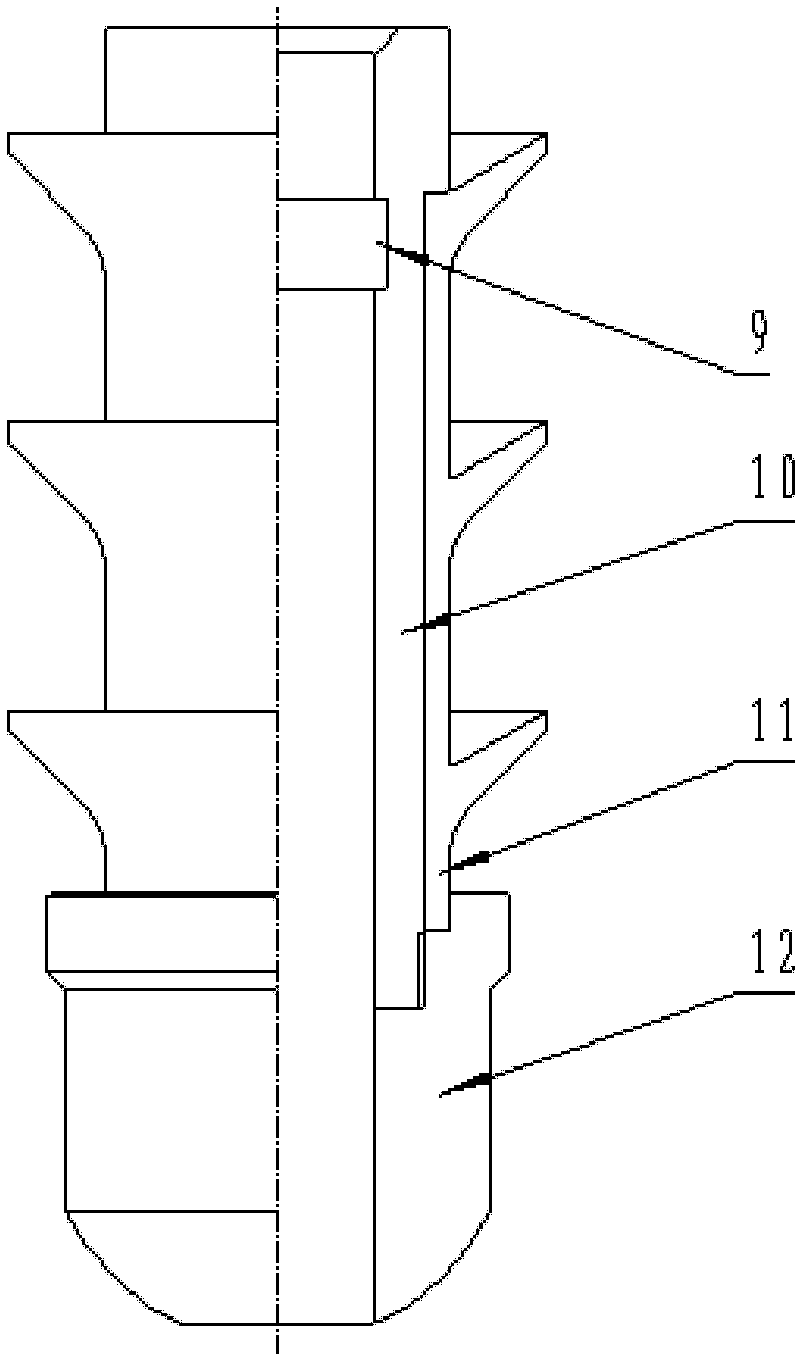

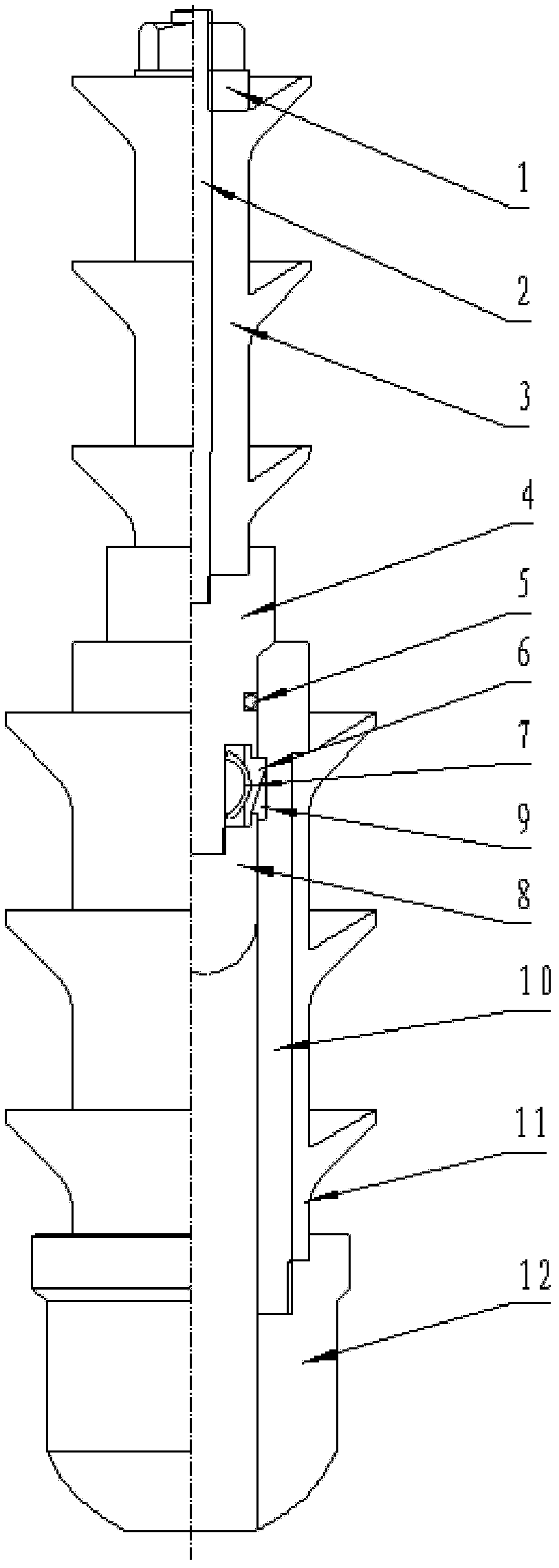

[0011] Such as figure 1 , figure 2 , image 3 As shown, a liner cementing rubber plug composite impact device is composed of a drill pipe rubber plug and a liner hollow rubber plug; the drill pipe rubber plug includes a fixed nut 1, a connecting rod 2, a small rubber bowl 3 and a bowl The seat 4, the fixed nut 1, the connecting rod 2, the bowl seat 4, and the guide head 8 are threaded in sequence from top to bottom. The connecting rod 2 is equipped with a small rubber bowl 3, and the outer side of the bowl seat 4 is provided with a sealing groove. A sealing ring 5 is installed inside, a clamping block 6 is installed on the outside of the bowl seat 4, and a return spring 7 is installed on the inside of the clamping block 6; the tail pipe hollow rubber plug includes a hollow core connector 10, a large rubber bowl 11 and a hollow guide bowl seat 12. The hollow core connecting body 10 is designed to be hollow. The inner wall of the hollow core connecting body 10 is designed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com