Magnetic suspension cylindrical linear movement guide rail pair

A technology of linear motion and magnetic suspension, applied in the field of guide rails, can solve the problems of unmentioned, waste of materials, unmentioned moving guide rail blocks, etc., and achieve the effect of easy processing and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

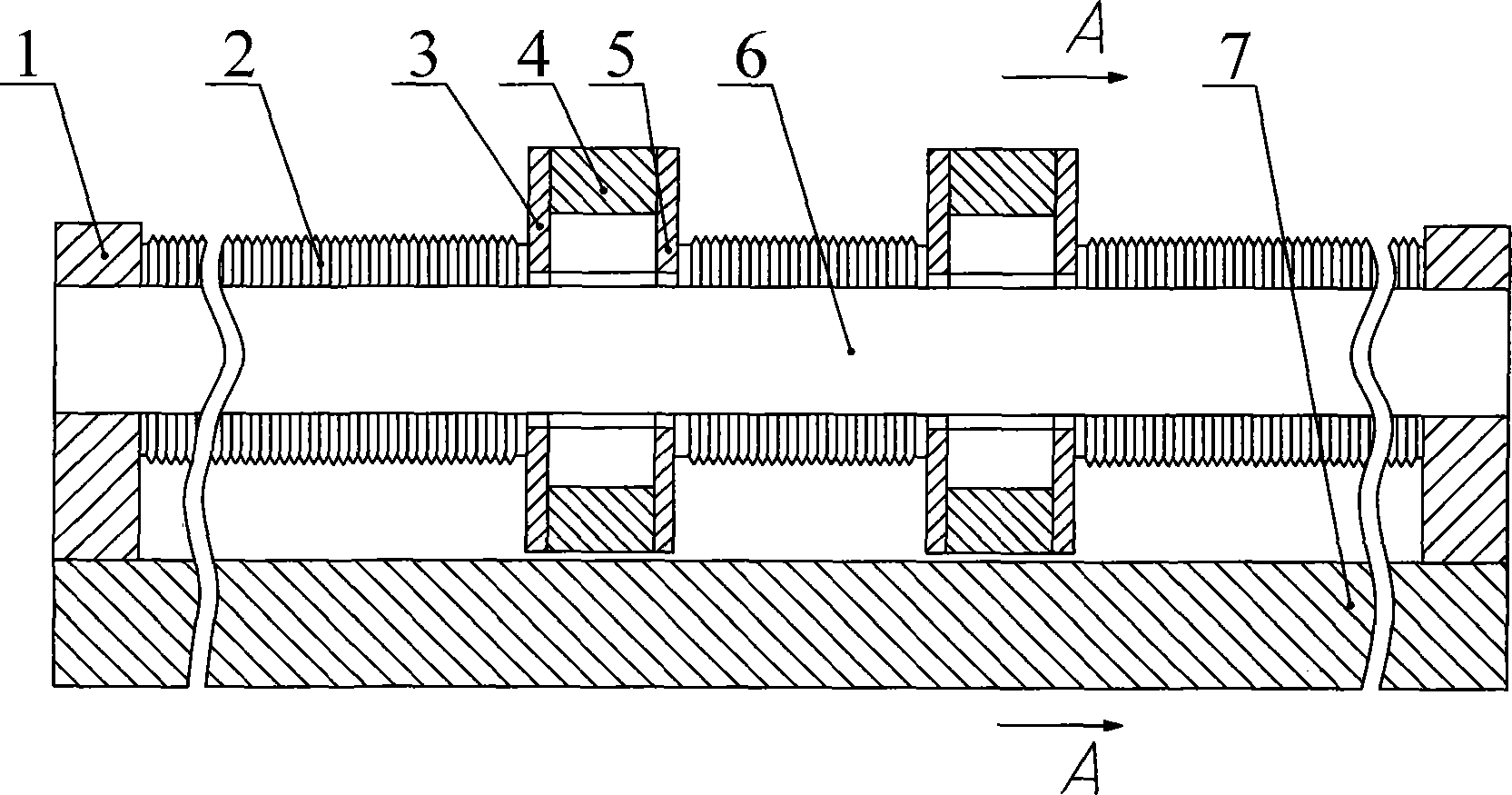

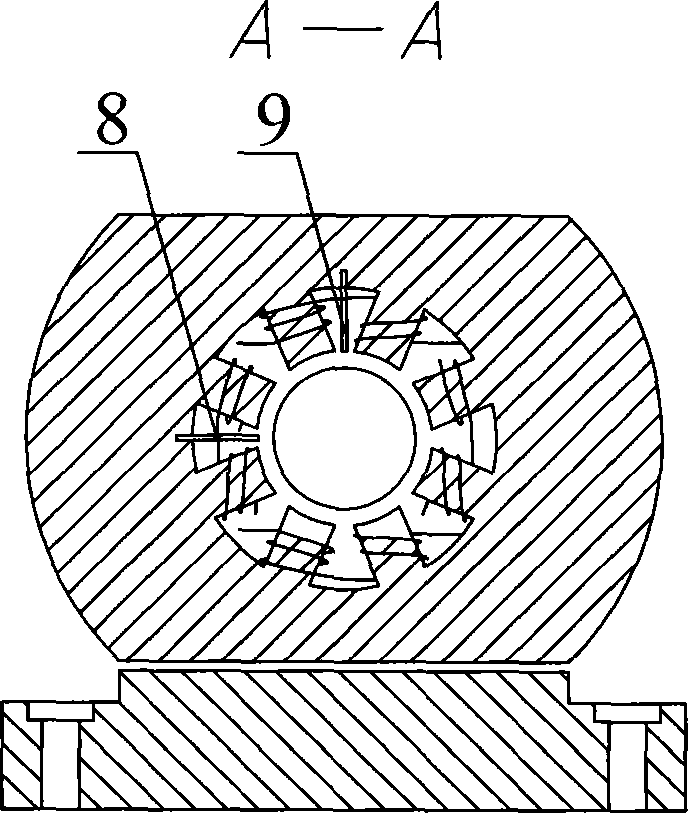

[0034] First, see attached figure 1 , 2 The magnetic levitation cylindrical linear motion guide rail pair includes a base 7, a support frame 1 installed at both ends of the base 7, a cylindrical support guide rail 6 installed on the support frame 1, and a magnetic levitation moving guide rail 4 set on the cylindrical support guide rail 6, The magnetic isolation plates 3 and 5 fixed at the two ends of the magnetic levitation guide rail 4, the organ type protective cover 2 which is set on the cylindrical support guide rail 6 and connected with the magnetic isolation plate 3 and the support frame 1, is installed at the level of the circumferential direction of the magnetic levitation guide rail 4 Displacement sensor 8 and vertical sensor 9.

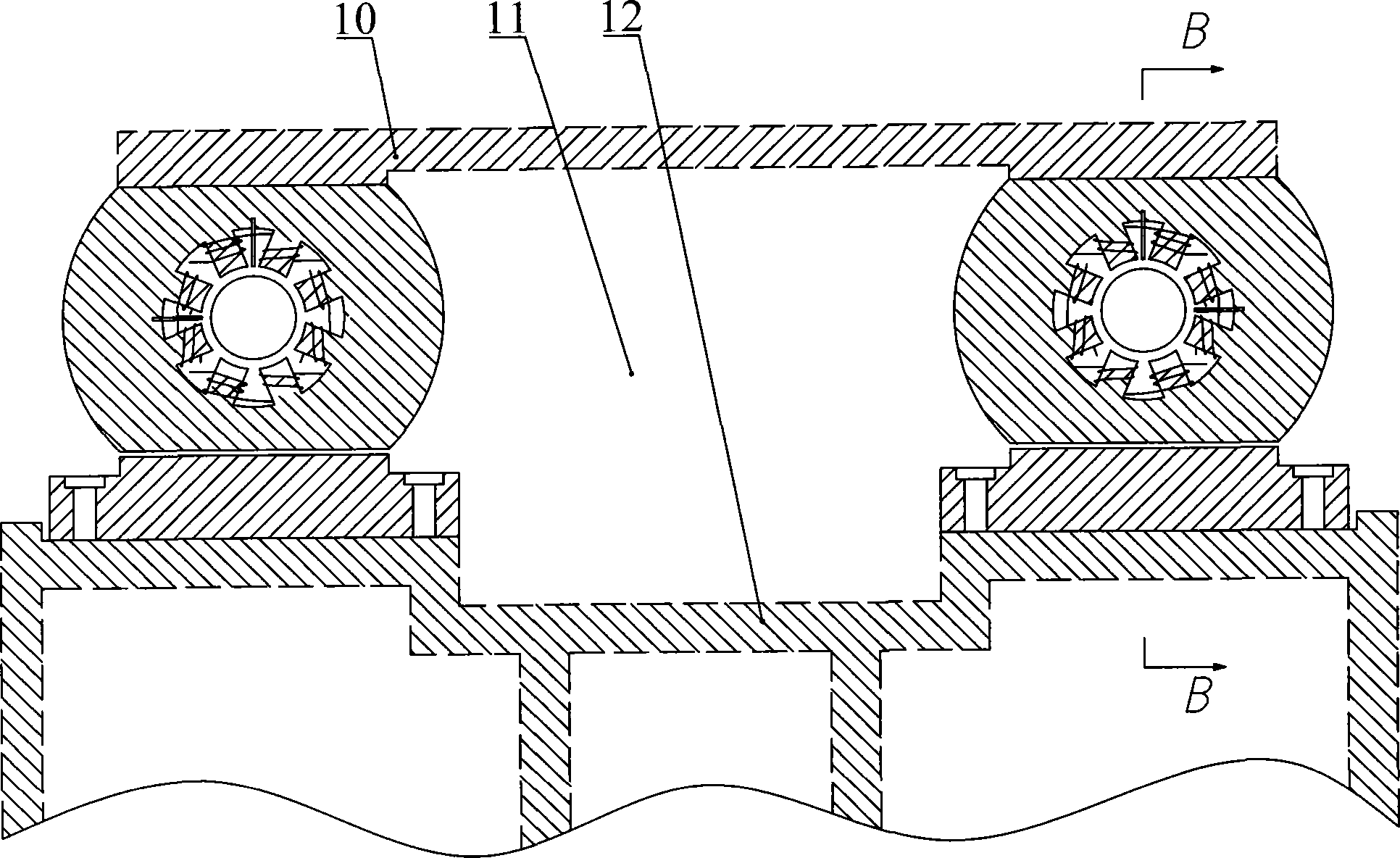

[0035] See attached image 3 , 4 , during practical application, the linear magnetic levitation cylindrical guide rails of the present invention are installed in pairs on the machine bed 12, the workbench 10 is installed on the magnetic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com