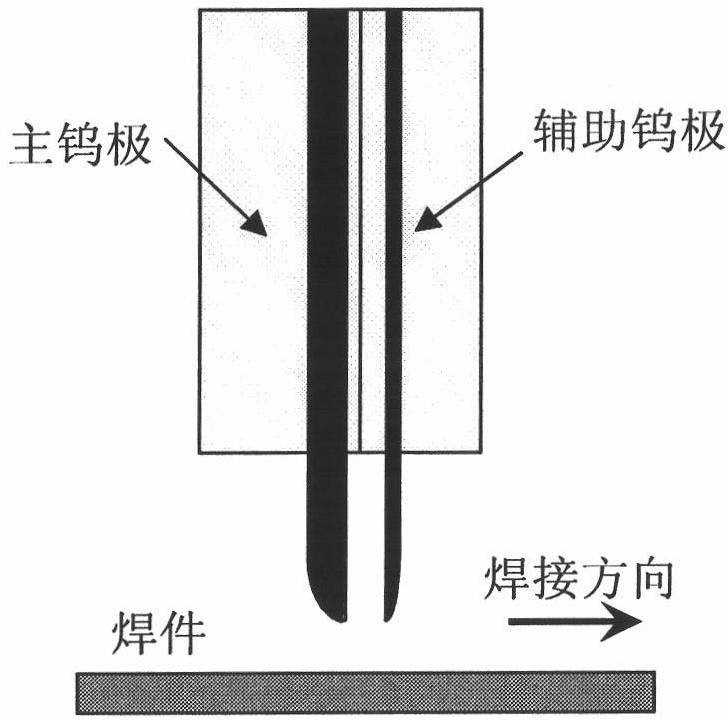

Coupling-arc AA-TIG welding method

A welding method and arc technology, applied in arc welding equipment, welding equipment, welding rod characteristics, etc., can solve the problems of difficult angle and spacing adjustment, difficult welding automatic production, and low welding production efficiency, so as to prevent undercut or hump Welding bead, full automation, and the effect of increasing welding penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The stainless steel plate is 8mm thick, and the welding speed is 500mm / min. The auxiliary arc parameters of coupled arc AA-TIG welding are shown in Table 1, and the main arc parameters are shown in Table 2.

[0018] Table 1 Auxiliary arc specification parameters

[0019]

[0020] Table 2 Main arc welding specification parameters

[0021]

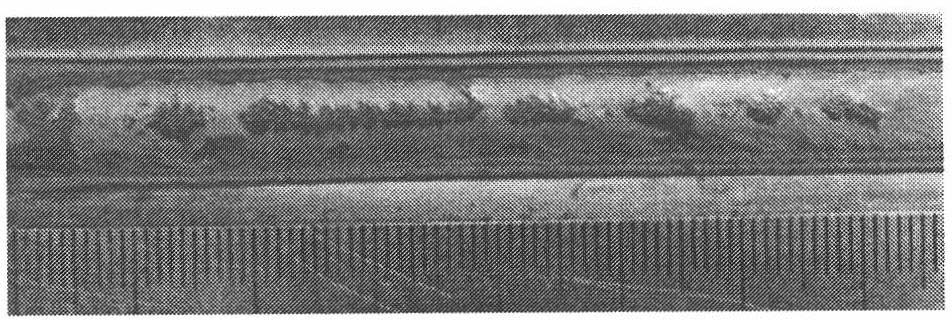

[0022] Under the welding parameters in Table 1 and Table 2, the weld surface of coupled arc AA-TIG welding is as follows figure 2 As shown, the weld surface is well formed without any undercut. The shape of the weld seam section is as image 3 As shown, the weld penetration reached 3.5mm. The weld surface shape of coupled arc TIG welding without adding active gas is as follows: Figure 4 As shown, severe humps appear on the surface of the weld. The shape of the weld seam section is as Figure 5 As shown, the weld penetration is only 1.9mm. This shows that the addition of active gas in coupled arc AA-TIG welding can not ...

Embodiment 2

[0024] The stainless steel plate is 5mm thick, and the welding speed is 800mm / min. The test compared the weld surface and cross-sectional shape of conventional TIG welding, coupled arc TIG welding and coupled arc AA-TIG welding. The traditional TIG welding parameters are shown in Table 3, the coupled arc AA-TIG welding auxiliary arc welding parameters are shown in Table 4, and the main arc welding parameters are shown in Table 5. Figure 6 For traditional TIG welding, the weld surface and cross-section are shaped, and a hump bead appears on the weld surface. and Figure 7 and Figure 8 The weld surface of medium coupled arc TIG welding and coupled arc AA-TIG welding is well formed. The use of coupled arc TIG welding and coupled arc AA-TIG welding can significantly improve the shape of the weld surface.

[0025] Table 3 Specification parameters of traditional TIG welding

[0026]

[0027] Table 4 Auxiliary Arc Specification Parameters

[0028]

[0029] Table 5 Main ...

Embodiment 3

[0032] The stainless steel plate is 5mm thick, and the welding speed is 1800mm / min. The test compared traditional TIG welding, coupled arc TIG welding and coupled arc AA-TIG welding. The specification parameters of the auxiliary arc in coupled arc AA-TIG welding are shown in Table 7, and the specification parameters of the main arc welding are shown in Table 8. Figure 9 Shown are the weld surface and cross-sectional morphology of traditional TIG welding, and the weld surface has obvious hump bead. Figure 10 For coupled arc TIG welding, the surface and section of the weld seam are formed, the surface of the weld seam has a slight undercut, and the penetration depth of the weld seam is only 0.4mm. Figure 11 For coupled arc AA-TIG welding, the surface and cross-sectional morphology of the weld seam has no undercut on the surface, and the weld penetration depth reaches 0.6 mm. In comparison, it can be seen that the coupled arc AA-TIG welding has obviously better weld surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com