Method for floating high-grade sulfur concentrate from lead-zinc tailings by flow separation and speed division method

A high-grade sulphur concentrate and sulphur concentrate technology, applied in flotation, solid separation and other directions, can solve the problems of adding large collectors, long flotation process, and large energy consumption in beneficiation, so as to improve the beneficiation index and reduce The effect of beneficiation cost, improving sulfur recovery rate index and concentrate grade index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1 (control sulfur concentrate grade is equivalent)

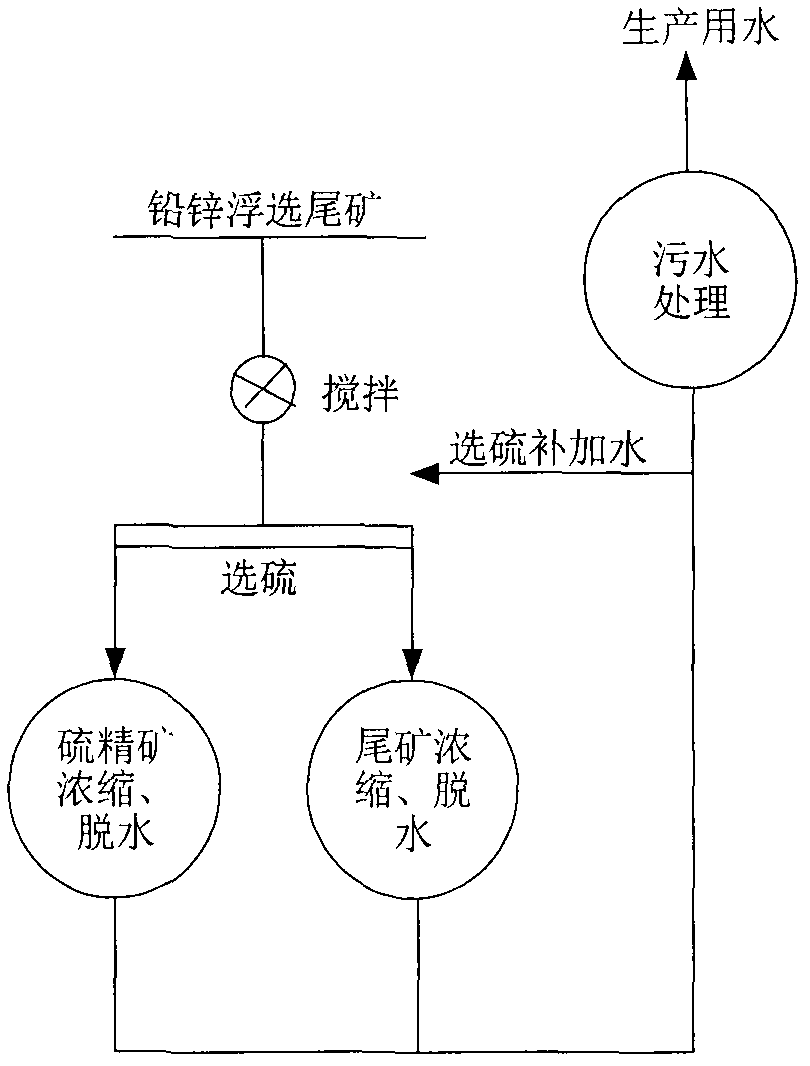

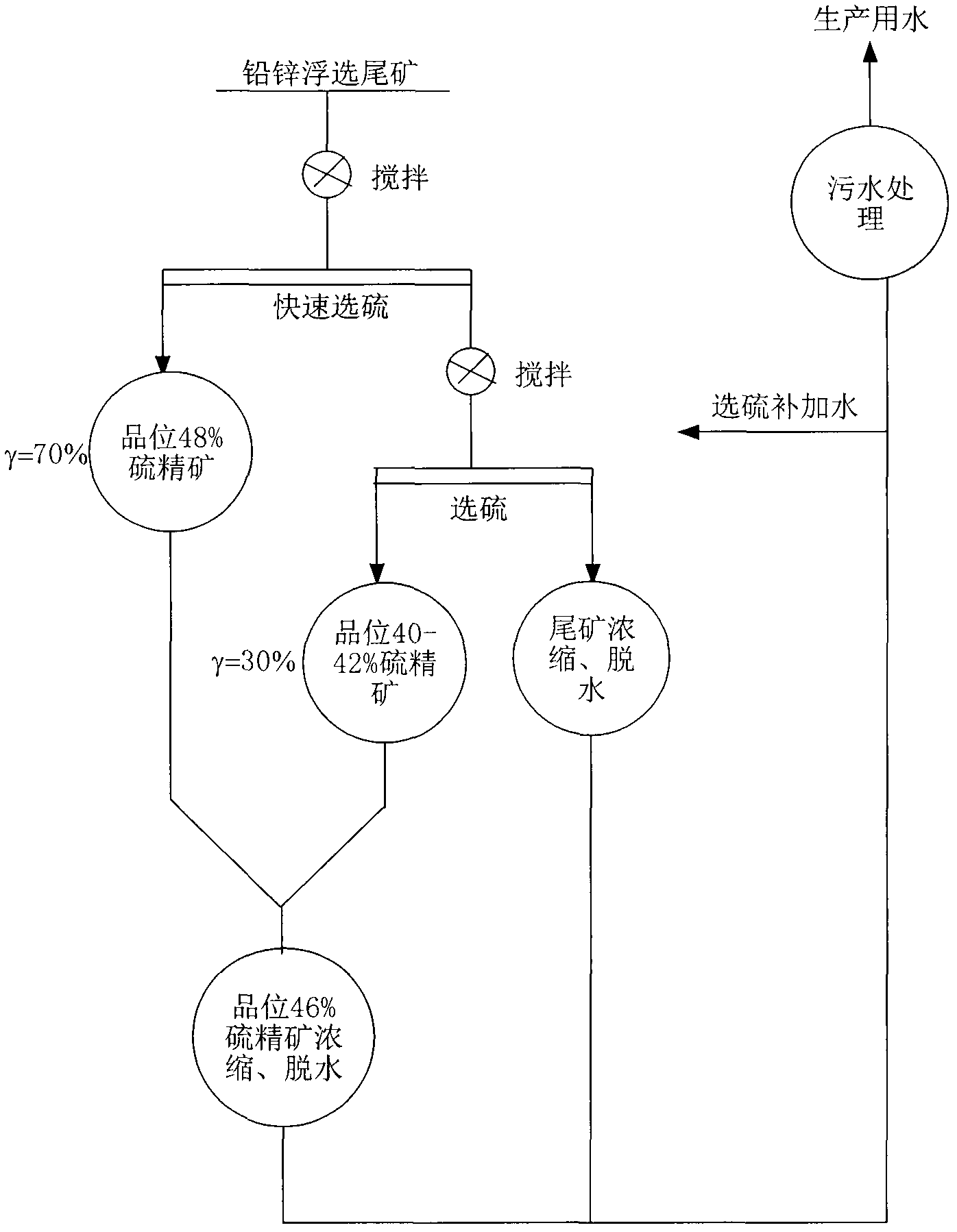

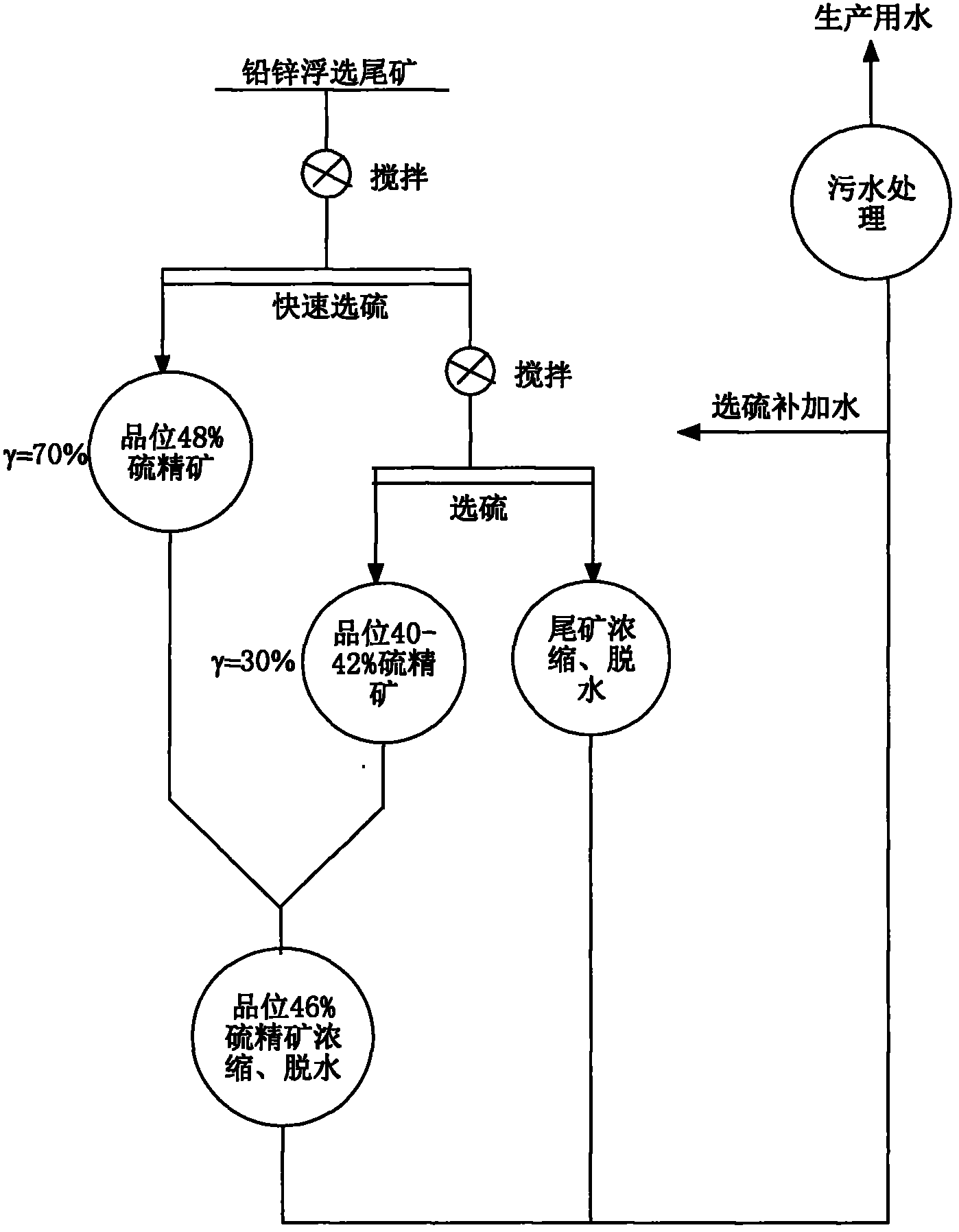

[0012] according to figure 1 , figure 2 In the process shown, the dressing plant can process 1,300 tons of raw ore dry ore per day, and 50 tons of lead-zinc tailings dry ore per hour.

[0013] The grades of sulfur concentrate obtained by controlling the two processes according to the following process are equivalent.

[0014] Conventional sulfur selection process ( figure 1 ): add sulfuric acid, butyl xanthate and 2# oil to the zinc-selected tailings with a concentration of 30% (the sulfur grade is 31.26%), and use a flotation machine to float the sulfur concentrate. The addition amount of 93% sulfuric acid is 10200g / t (the pH value of the pulp is 6.8), the addition amount of butyl xanthate is 590g / t, and the addition amount of 2# oil is 5g / t; The concentrated overflow water is reused for sulfur selection. The test results are shown in Table 1, and the grade of the obtained sulfur concentrate is 46.68...

Embodiment 2

[0021] Embodiment 2 (control sulfur concentrate recovery rate is quite)

[0022] according to figure 1 , figure 2 In the process shown, the dressing plant can process 1,300 tons of raw ore dry ore per day, and 50 tons of lead-zinc tailings dry ore per hour.

[0023] The recovery rate of sulfur concentrate obtained by controlling the two processes according to the following process is equivalent.

[0024] Conventional sulfur selection process ( figure 1 ): add sulfuric acid, butyl xanthate and 2# oil to the zinc-selected tailings with a concentration of 30% (the sulfur grade is 31.26%), and use a flotation machine to float the sulfur concentrate. The addition amount of 93% sulfuric acid is 9800g / t (the pH value of the pulp is 7.0), the addition amount of butyl xanthate is 660g / t, and the addition amount of 2# oil is 8g / t; the concentration and dehydration of sulfur concentrate and sulfur tailings The concentrated overflow water is reused for sulfur selection. The test res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com