Rotating speed dynamic adjusting method and corresponding device, system and physical layer interface

A technology of dynamic adjustment and rotation speed, applied in control systems, motor control, electrical components, etc., can solve the problems of signal accuracy deterioration, affecting control accuracy and processing production, so as to increase equipment cost, improve control accuracy, and ensure success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

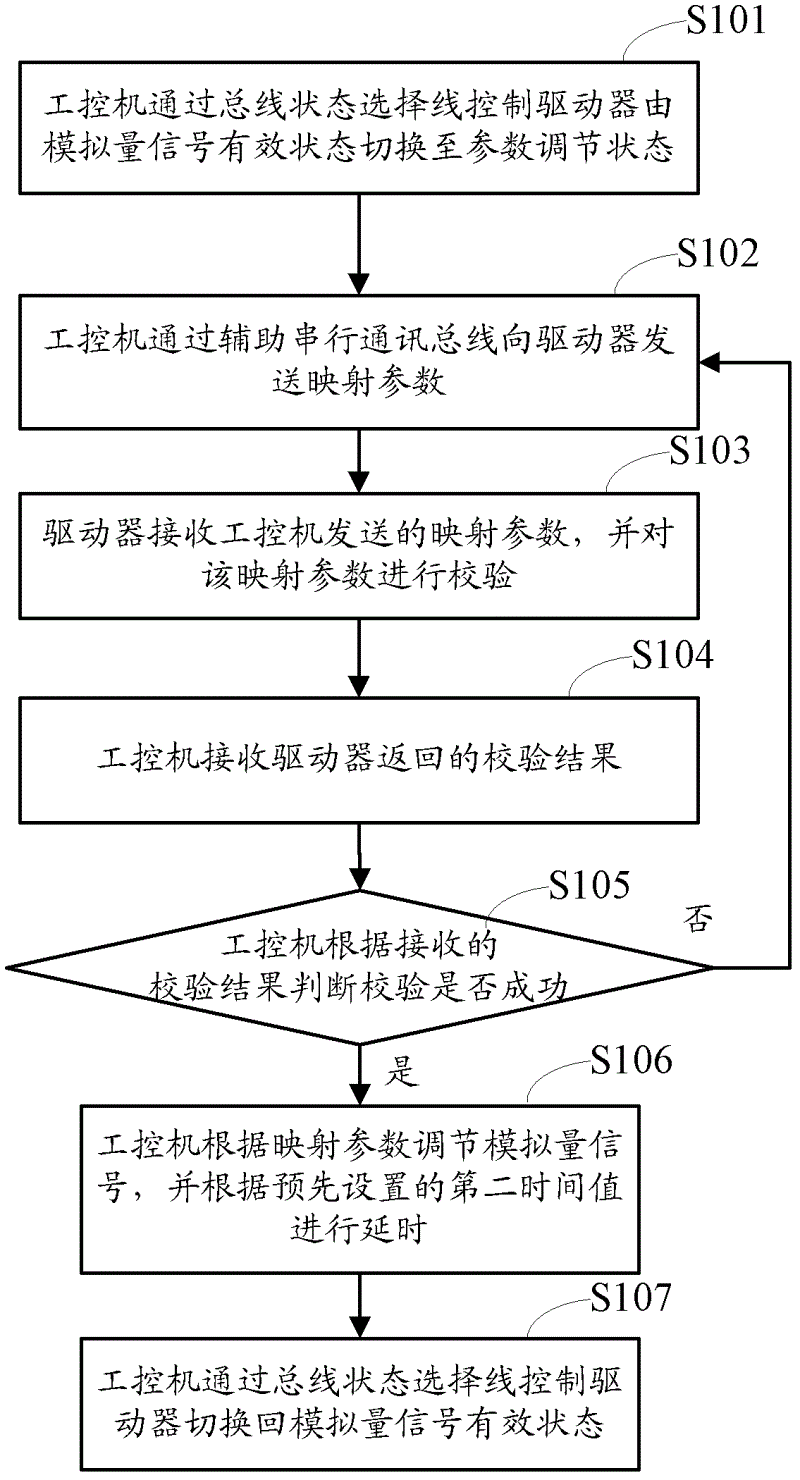

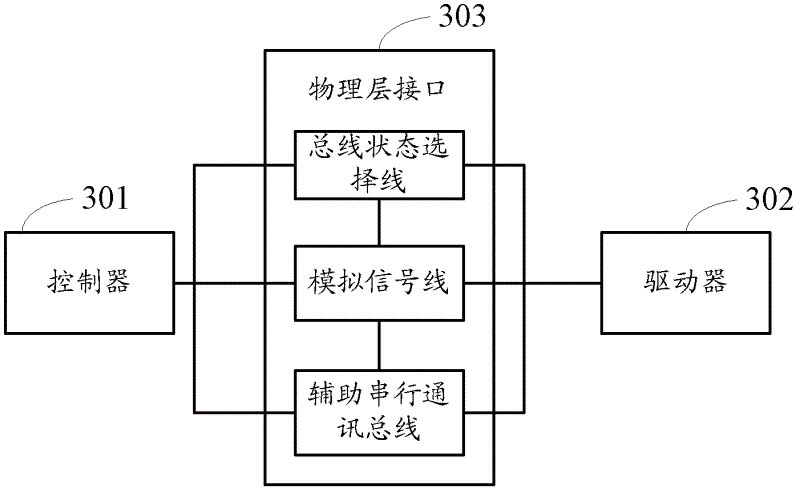

[0053] figure 1 It is an embodiment of the speed dynamic adjustment method of the present invention. In this embodiment, the industrial computer is connected to the driver through the analog signal line and the auxiliary serial bus, and the driver is connected to the motor. The industrial computer sends an analog signal to the driver through the analog signal line, and the driver converts the analog signal into a driver speed command and sends it to the motor to control the operation of the motor. Among them, there is a mapping relationship between the analog signal and the rotational speed command of the driver. The auxiliary serial communication bus can be CAN bus or any other effective industrial bus, such as Modbus, etc.

[0054] The flow of the speed dynamic adjustment method is as follows: figure 1 As shown, it specifically includes the following steps:

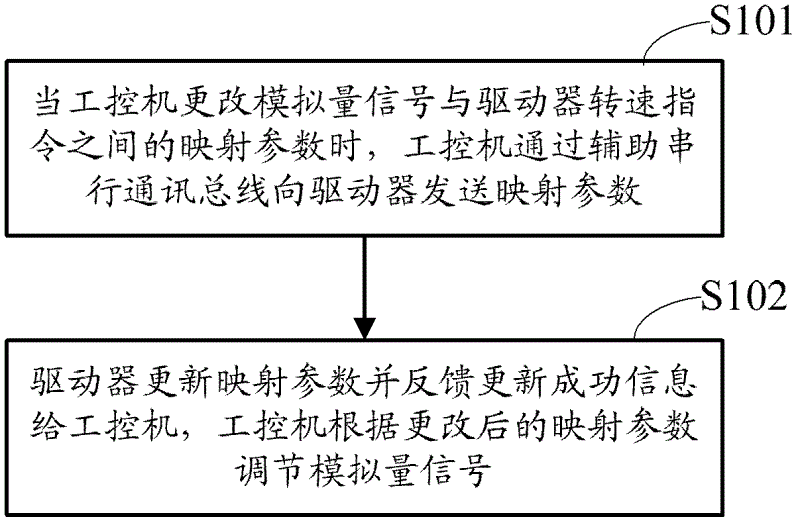

[0055] Step S101, when the industrial computer changes the mapping parameters between the analog signal and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com