Solar battery and component testing system based on Lab VIEW

A solar cell and testing system technology, applied in the testing of single semiconductor devices, electrical components, monitoring of photovoltaic systems, etc., can solve the problems of increased cost, volume, large mass, and high human error factors, and achieve cost savings, sampling frequency and High data accuracy and the effect of eliminating the interference of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

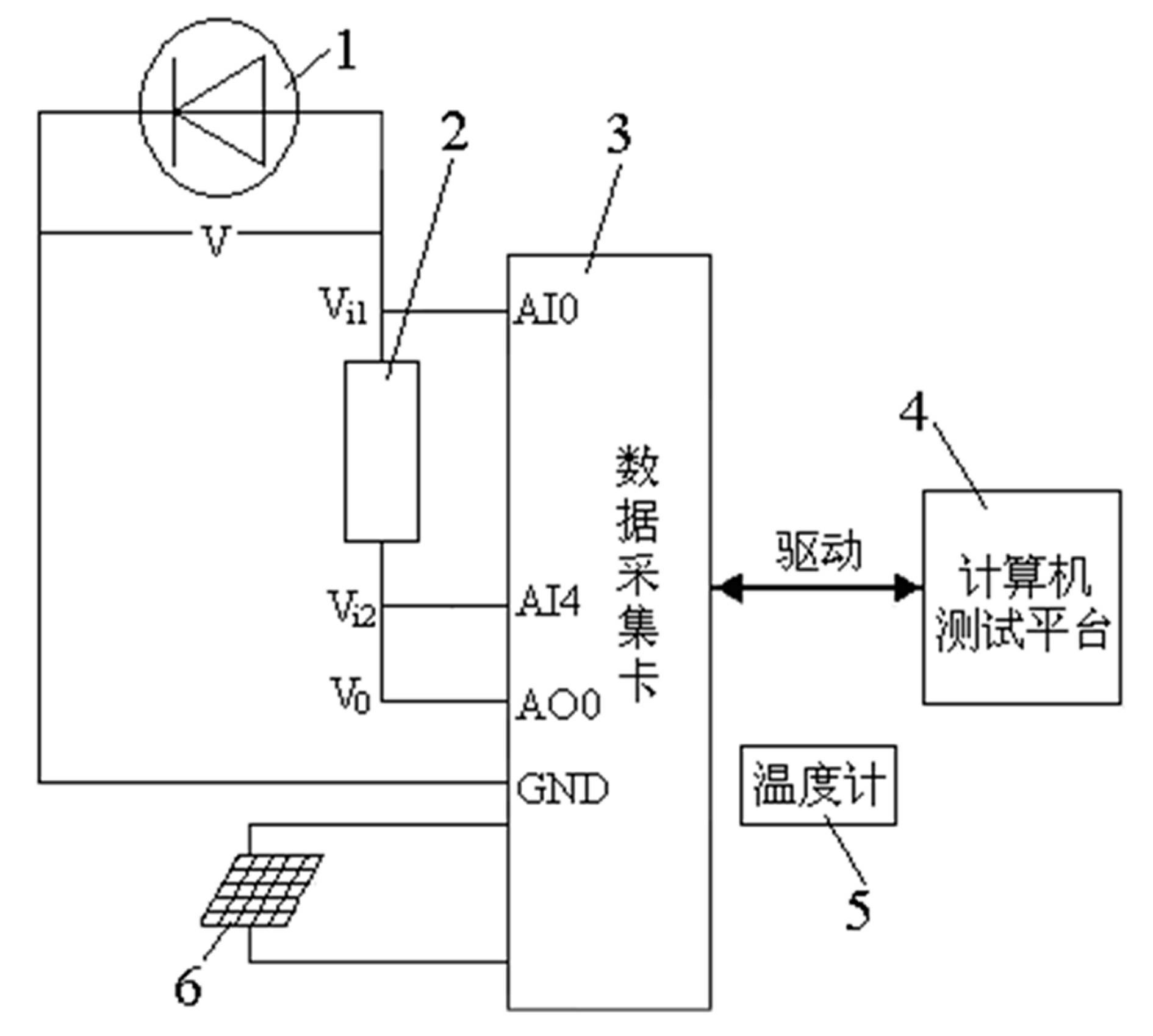

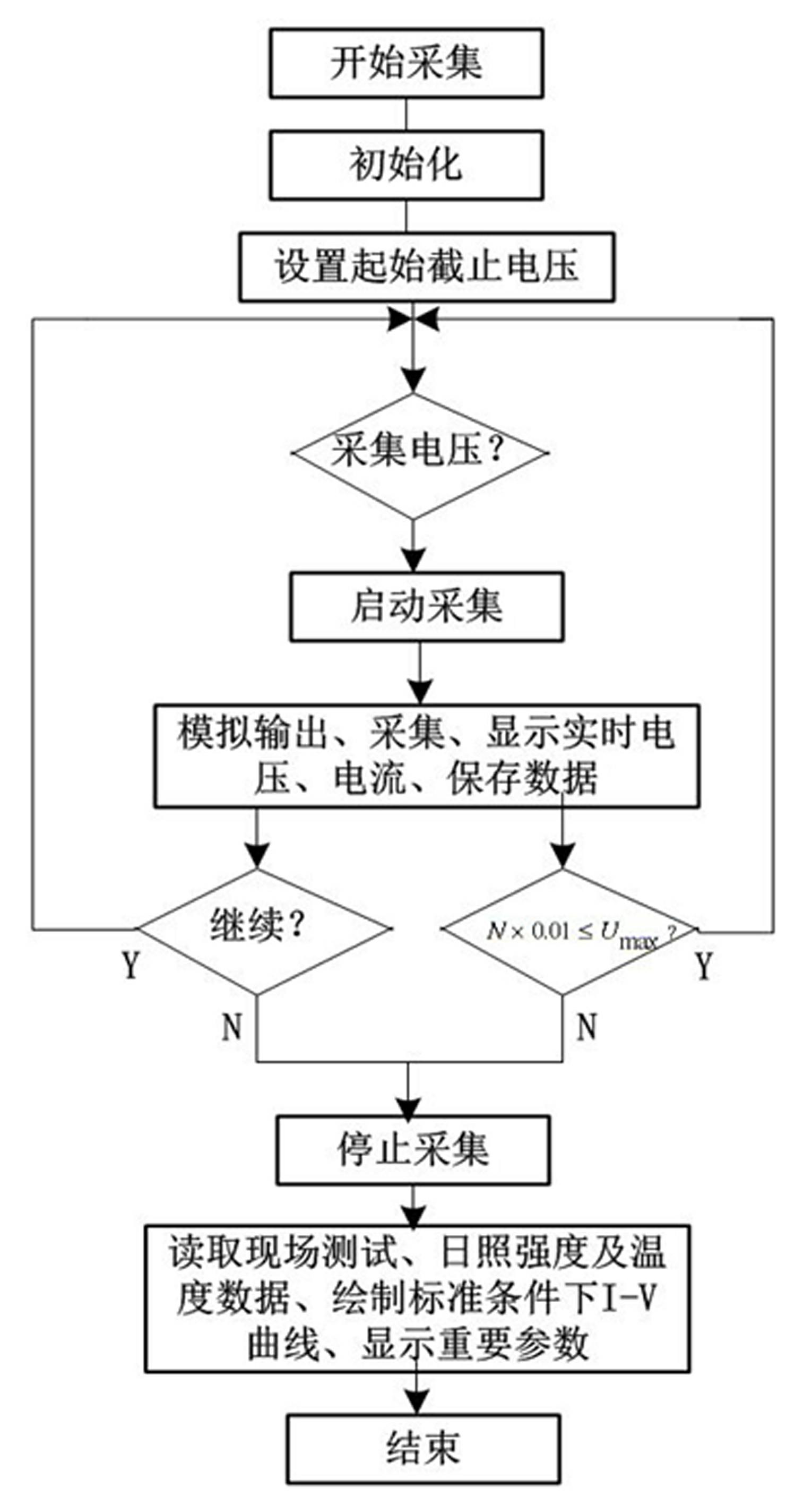

[0020] A load resistor is used in the existing solar cell test system, and the I-V characteristic curve of the solar cell is obtained by changing the resistance value of the load resistor during the test. However, due to the internal resistance in the actual circuit, the solar cell cannot reach a complete short circuit state, so that the existing test system cannot obtain a complete I-V characteristic curve of the solar cell. In order to overcome the problems existing in the prior art, the present invention provides a solar cell and component testing system based on LabVIEW, which can obtain a complete solar cell I-V characteristic curve. The structure of an embodiment of the test system is as figure 1 As shown, including data acquisition card 3 and thermometer 5, data acquisition card 3 is connected with sampling resistor 2, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com