Vibration sensor examination and calibrating device and usage method

A vibration sensor and calibration device technology, applied in measurement devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as the inability to obtain the dynamic characteristics of the vibration sensor, the inability to obtain the broadband performance of the vibration sensor in the frequency domain, etc., to improve the calibration Pass rate, improve inspection and calibration accuracy, and improve the effect of inspection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

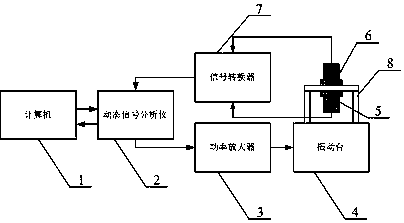

[0038] Such as figure 1 As shown, a vibration sensor inspection and calibration device includes a computer 1, a dynamic signal analyzer 2, a power amplifier 3, a vibration table 4, a standard vibration sensor 5, a calibrated vibration sensor 6, a signal converter 7 and a sensor mounting frame 8 ; The dynamic signal analyzer 2 has 1 signal output terminal and 2 signal input terminals, wherein one signal input terminal is connected to the computer 1 network interface by a network twisted pair to realize real-time communication, and the dynamic signal analyzer 2 output terminals Connect to the input end of the power amplifier 3 through a coaxial cable; the output end of the power amplifier 3 is connected to the input end of the vibration table 4 through a dedicated cable; the standard vibration sensor 5 and the vibration sensor 6 to be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com