Low heat mass firing boiler

A boiler, low heat technology, applied in the field of boilers, can solve the problems of using low fuel value fuel, temperature affected by water wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

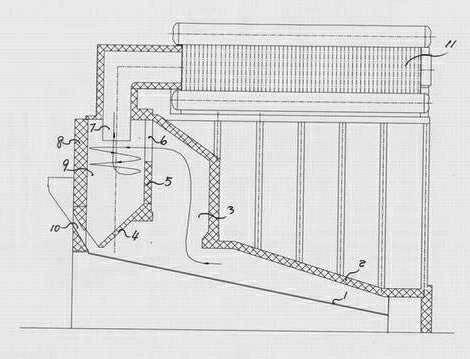

[0005] In order to use low calorific value fuel, the present invention firstly separates the furnace from the pot so that the inner temperature of the furnace will not be affected by the cold water wall; Pot dust pollution. Its specific technical solution is that a vertical partition wall 5 is provided between the rear arch 2 and the front wall 8 above the reciprocating grate 1 to separate the rear arch and the front wall into a furnace 3 and a flue gas dust removal chamber 9, where The upper part of the partition wall 5 is provided with a flue gas port 6, the upper part of the dust removal chamber 9 is provided with a cyclone dust collector 7, and the lower end of the front wall is provided with a fuel injection port 10 opposite to the front end of the reciprocating grate, and the lower end of the partition wall has a The front arch 4 inclined towards the front end of the reciprocating fire grate forms a fuel inlet between the front oven and the reciprocating fire grate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com