Combined type modular house with high-strength roof structure

A roof structure and modularization technology, applied to roofs, building components, building structures, etc., can solve problems such as poor internal connectivity, poor integrity, and unreasonable use of space planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

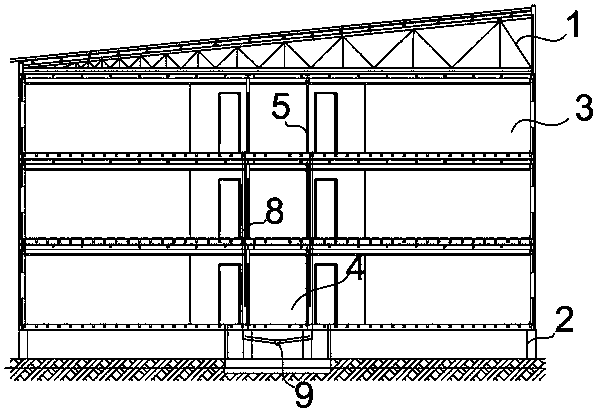

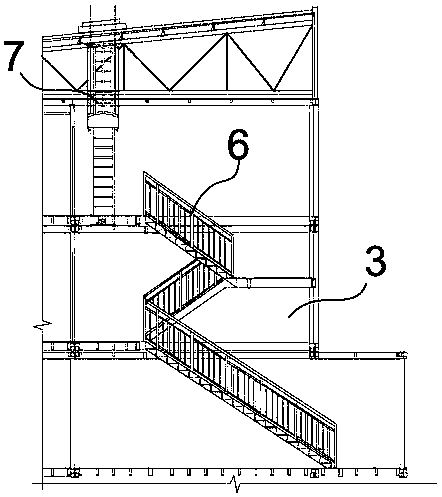

[0030] As shown in the figure, the present invention includes a roof 1, a multi-storey modular housing unit integrated under the roof and a support frame 2 located below the modular housing unit integration, wherein,

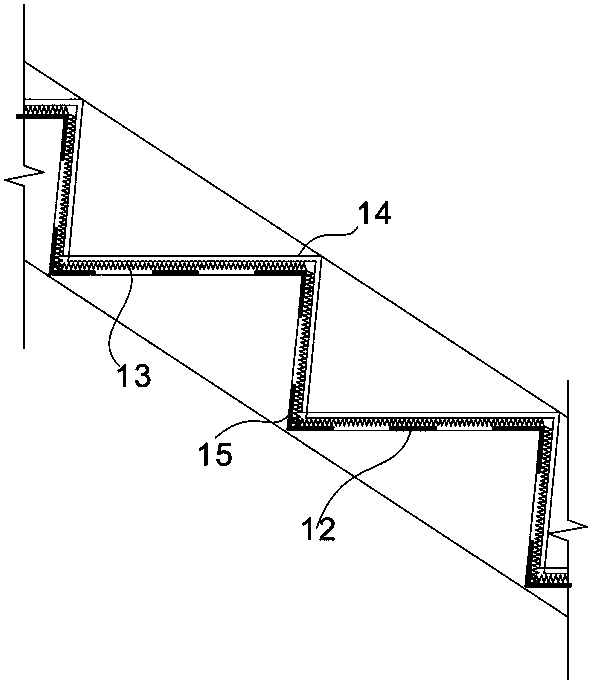

[0031] The modular housing unit integration includes a plurality of modular housing units 3 connected side by side, and the modular housing units in each modular housing unit integration correspond to each other in the vertical direction, and the middle side walls of the modular housing units communicate with each other. A connecting passage 4 is provided, and partitions 5 are respectively arranged on both sides of the connecting passage, wherein one modular housing unit is vertically connected to the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com