A device for enrichment, extraction and separation of associated rare and precious metal elements

A technology of metal elements and separation equipment, which is applied in the direction of improving process efficiency, can solve problems such as difficult extraction work, high procurement costs and labor costs, and uncontrollable time, so as to facilitate dissolution and extraction treatment, high burning efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

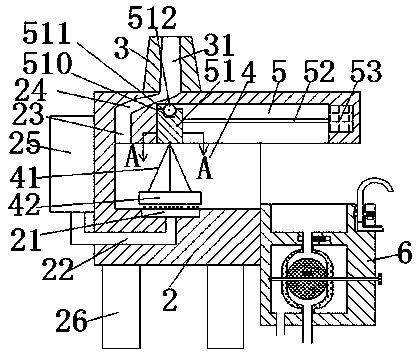

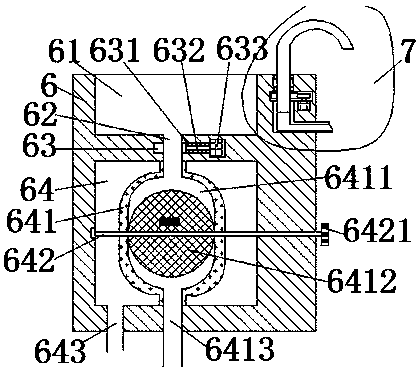

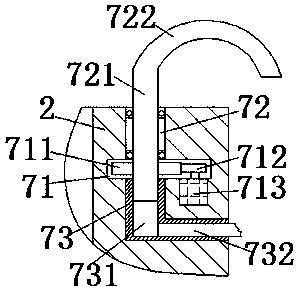

[0015] like Figure 1-Figure 4As shown, an associated rare and precious metal element enrichment, extraction and separation device of the present invention includes a burning body 2 and an extraction body 6 fixedly arranged at the bottom of the right end of the burning body 2. The burning body 2 is provided with a second A cavity 4, the right end surface of the burning body 2 is provided with a protruding portion 26 located on the top of the first cavity 4, and a left-right communication is provided between the burning body 2 and the protruding portion 26 The first guide chute 5, the part of the first guide chute 5 located in the burning body 2 communicates with the first cavity 4, and the first guide chute 5 is slidingly fitted with a first Guide slider 51, the first guide slider 51 is internally threaded and connected with a first adjusting threaded rod 52 extending left and right, a first motor 53 is embedded in the inner wall of the right end of the first guide chute 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com