LED (light emitting diode) strip quick connecting structure

A technology of fast connection and LED substrate, which is applied in the direction of lighting devices, light sources, lighting device components, etc., can solve the problems of wiring time and cumbersome procedures, troublesome wiring, and many steps of LED strips, etc., and achieve simplified wiring steps and operability , compact structure, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

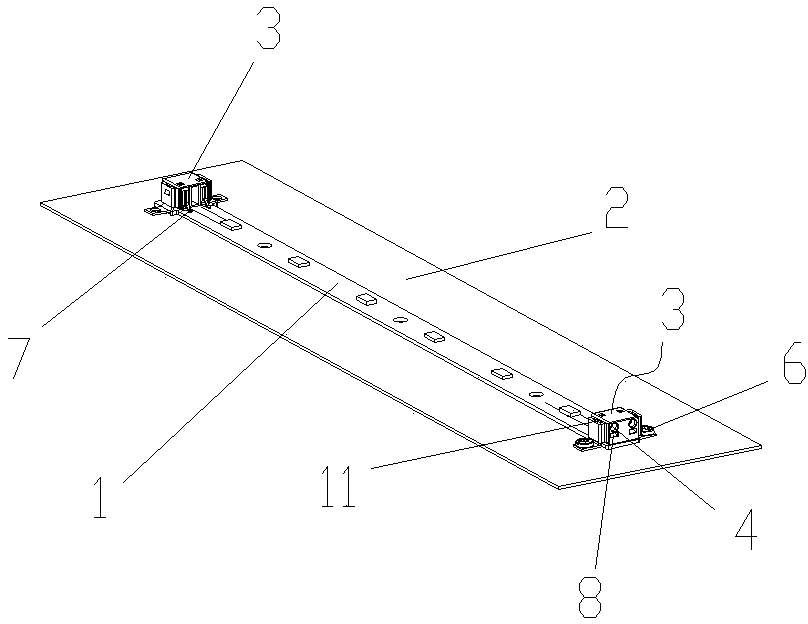

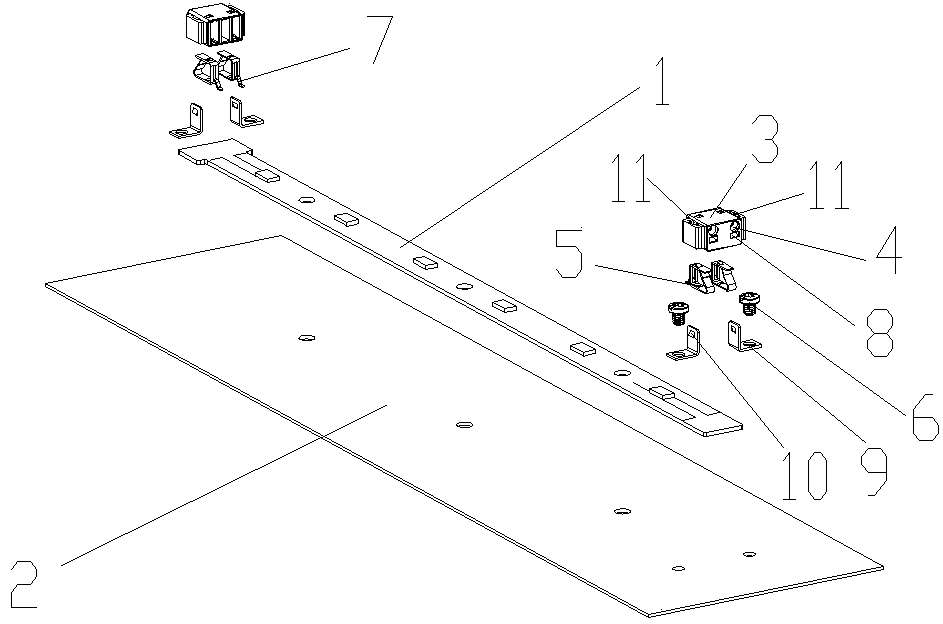

[0014] A LED strip quick connection structure described in Embodiment 1 of the present invention, such as figure 1 , figure 2 As shown, it includes an LED substrate and an LED strip 1 arranged on the LED substrate 2. The two ends of the LED strip are separately provided with connecting terminals 3 that can communicate with external wires. The fastening parts match the fastening openings; the fastening parts are all arranged on the LED substrate and fixedly connected with the LED substrate by screws. The fastening parts are two symmetrical L-shaped lugs 9, which are distributed on both sides of the periphery of the end of the LED bar, and each L-shaped lug is provided with an elastic chamfered bayonet 10; the buckle is The through groove 11 interlocked with the L-shaped lug is provided with a notch matched with the chamfered bayonet in the through groove.

[0015] The connecting terminal is provided with a socket 4 that can accommodate the insertion of a wire. The connecting...

Embodiment 2

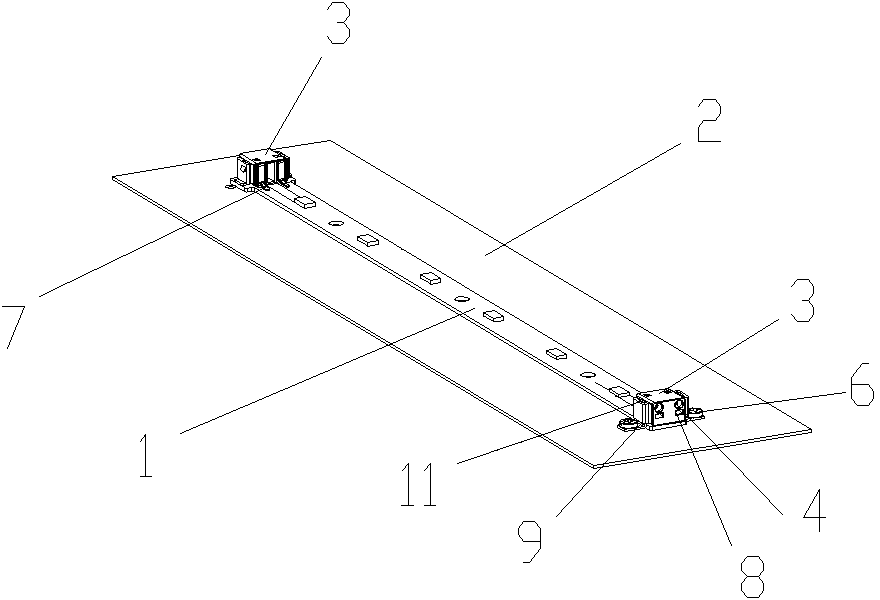

[0018] A LED bar quick connection structure described in Embodiment 2 of the present invention, such as image 3 , Figure 4 As shown, it includes an LED substrate 2 and an LED strip 1 disposed on the LED substrate. The two ends of the LED strip are separately provided with connecting terminals 3 that can communicate with external wires. Both the LED substrate and the LED strip are provided with buckles. There is a buckle on the LED board that is fastened with the buckle; the LED substrate is provided with a buckle that is buckled with the terminal at one end of the LED strip, and the LED strip is provided with another buckle that is buckled with the terminal at the other end. connected; the fastening piece set on the LED substrate is fixed to the LED substrate by screws 6 . The fastening piece is two symmetrical L-shaped lugs 9, wherein two L-shaped lugs are distributed on both sides of the periphery of the end of the LED strip, and the other two L-shaped lugs are distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com