Adjustable jetting support for dust control of comprehensive mechanized excavation surface of mine

An adjustable, fully-mechanized excavation face technology, applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of inability to adjust, small nozzle outlet pressure, capture and settlement, etc., to achieve easy operation, maintenance and replacement, and uniform pressure distribution , Improve the effect of dust suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

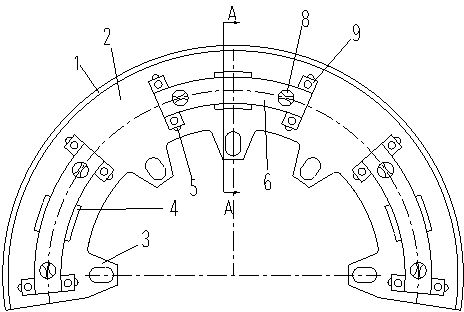

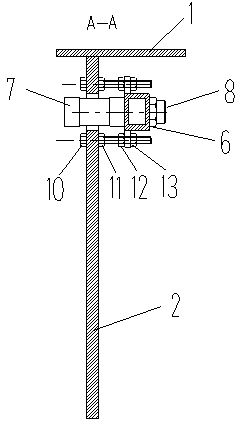

[0013] The adjustable spray support for the prevention and control of dust in fully mechanized mine excavation of the present invention is mainly composed of a baffle plate 1, a support plate 2, a connecting ear 3, a spray head installation branch pipe 6, and a spray head 8; The number of connecting ears 3 and multiple connecting ears 3 is determined according to the actual situation, and there are 5 shown in the accompanying drawings. Each connecting ear 3 is provided with a fixing hole corresponding to the screw hole of the cutting head support frame of the roadheader. The support plate 2 is fixed on the cutting arm of the fully mechanized excavator by screws. One passes through the input port through-hole 4 of input pipe 7, and the orifice of input port through-hole 4 is rectangle, and a plurality of input port through-holes 4 are 2-4, arrange according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com