Fork arm type electric glass lifter

A glass lifter and electric technology, which is applied in the field of auto parts, can solve problems such as glass breakage, door guide rail damage, and impact on passenger safety, and achieve the effects of reducing manufacturing process complexity, reducing manufacturing costs, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

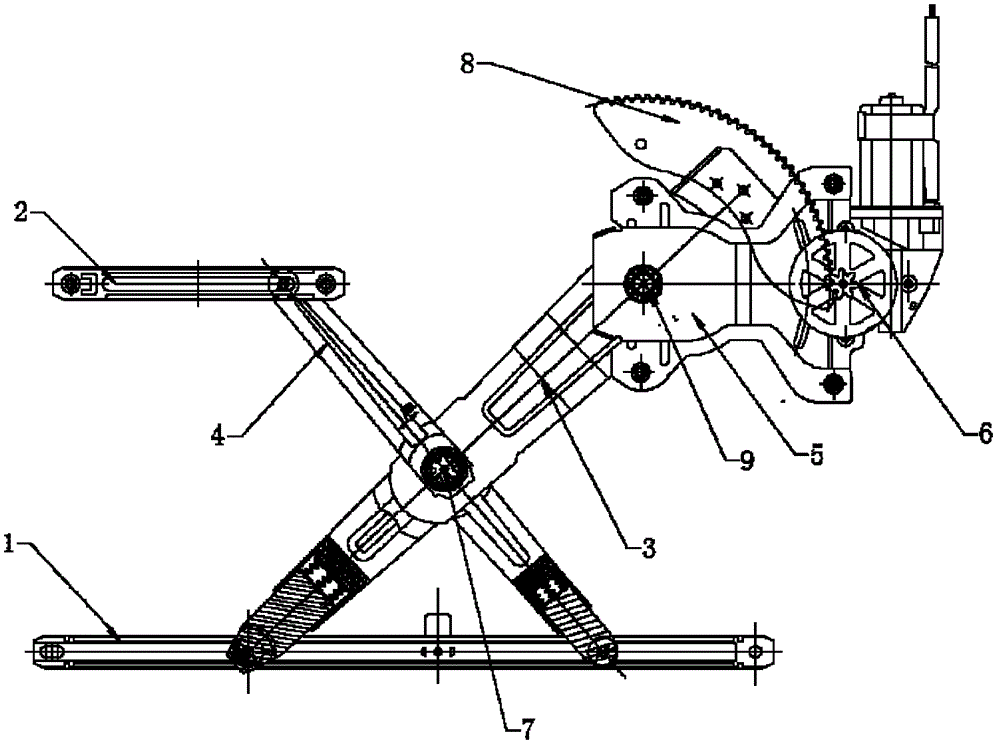

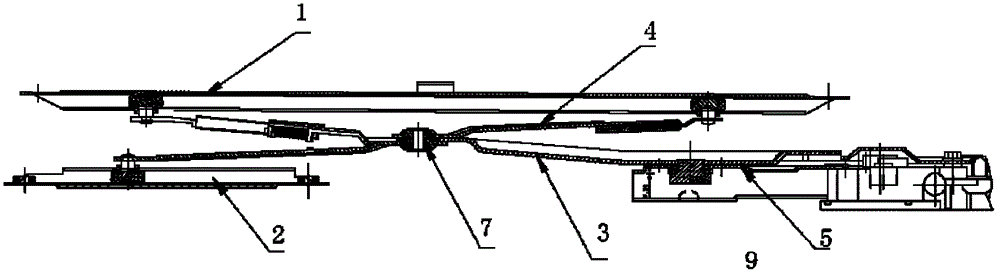

[0031] Such as figure 1 , 2 As shown, the present invention provides a fork arm type electric window lifter, including a moving guide rail 1, a fixed guide rail 2, a driving arm 3, a driven arm 4, a panel 5 and a driving gear 6, the driving arm 3 and the driven arm 4 The active arm 3 is hinged to the panel 5 through the hinge 7 in an X-shaped hinge. The driving gear 6 drives the main arm 3 to move, and the main arm 3 drives the moving guide rail 1 to move vertically up and down through the conversion of the fixed guide rail 2 and the driven arm 4. Vertical movement of glass up and down.

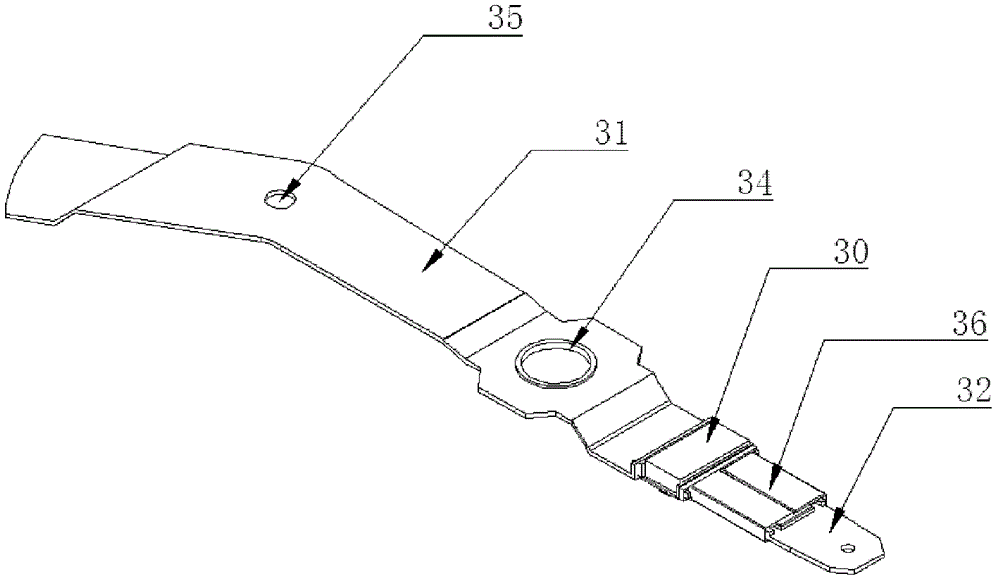

[0032] Such as Figure 3-5 As shown, the active arm 3 includes a first long arm 31, a second long arm 32 and a first spring 33. One end of the first long arm 31 is provided with a gear sector 8 that cooperates with the driving gear 6, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com