Transmission assembly of agitator type washing machine

The invention relates to a washing machine and agitating technology, which is applied to the transmission assembly field of agitating washing machines, and can solve the problems of uncoordinated coordination between brakes and drives, shortened service life of the drive motor, inconvenient installation and maintenance, etc., and achieves simple structure, accurate braking, and occupancy. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

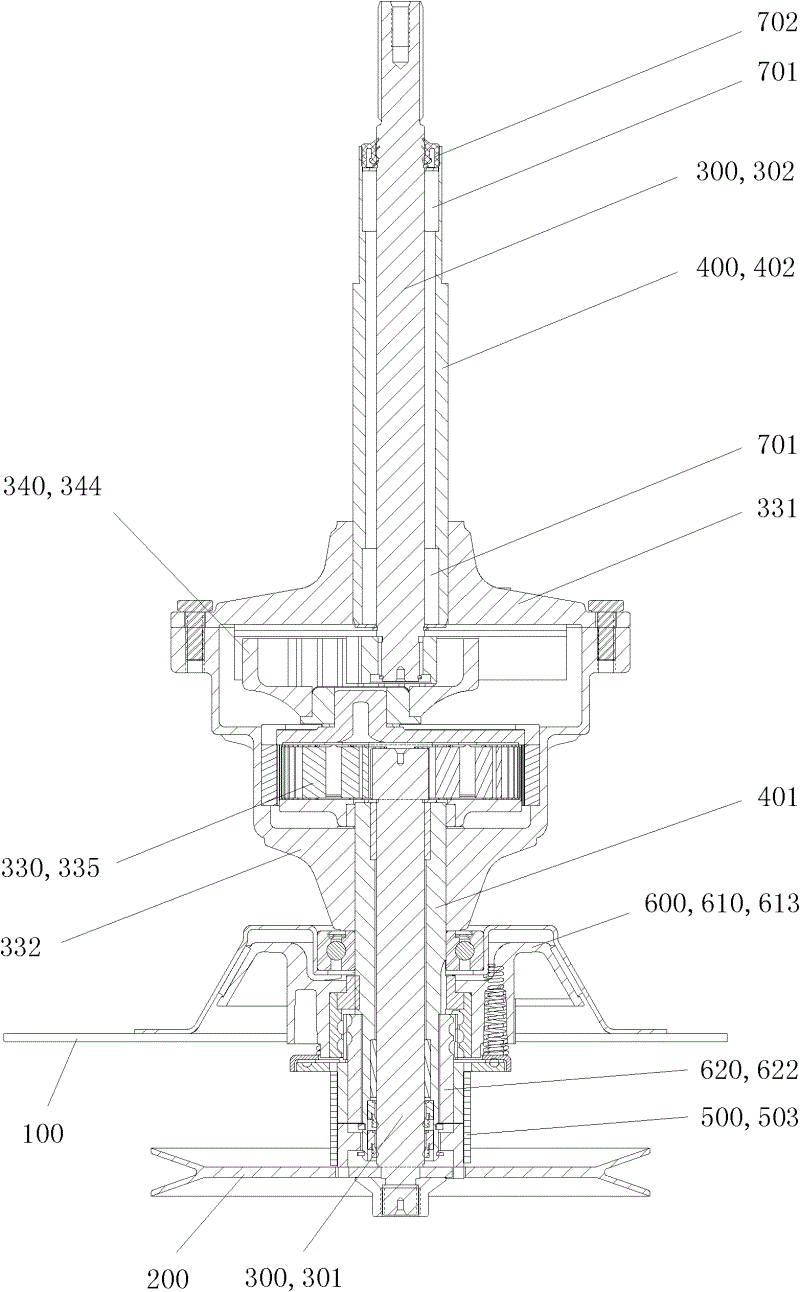

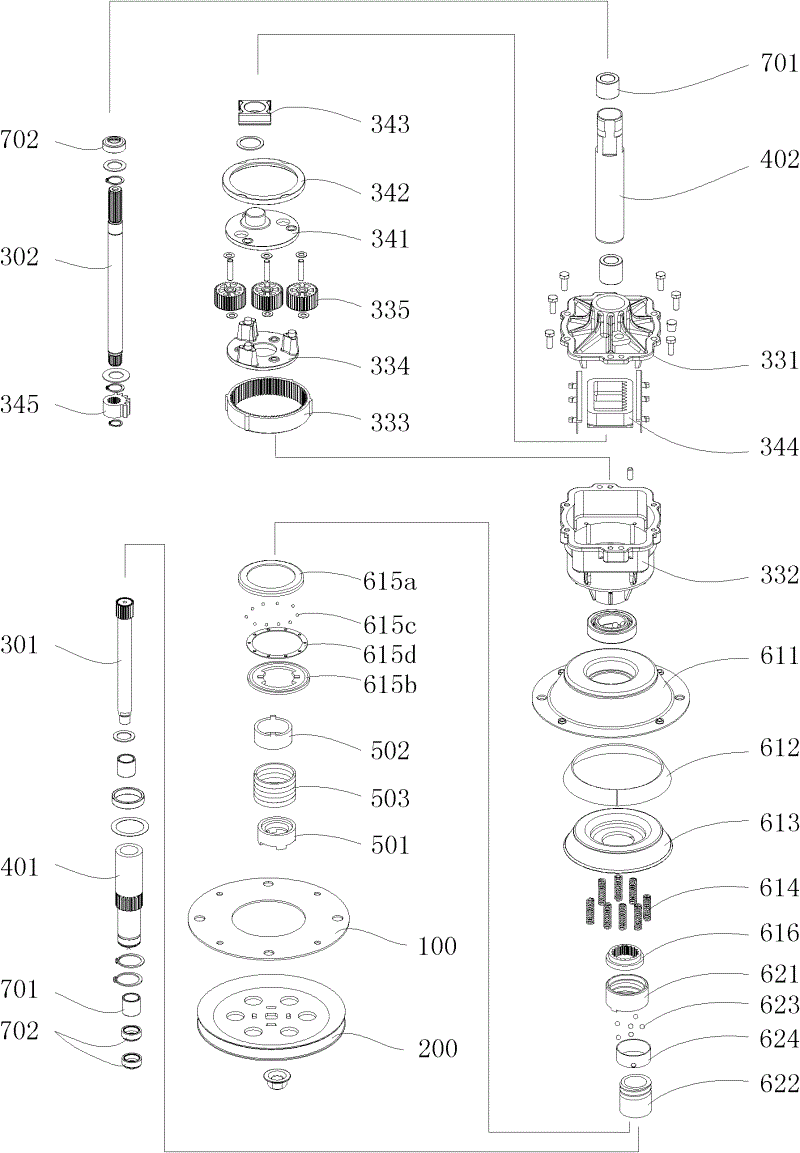

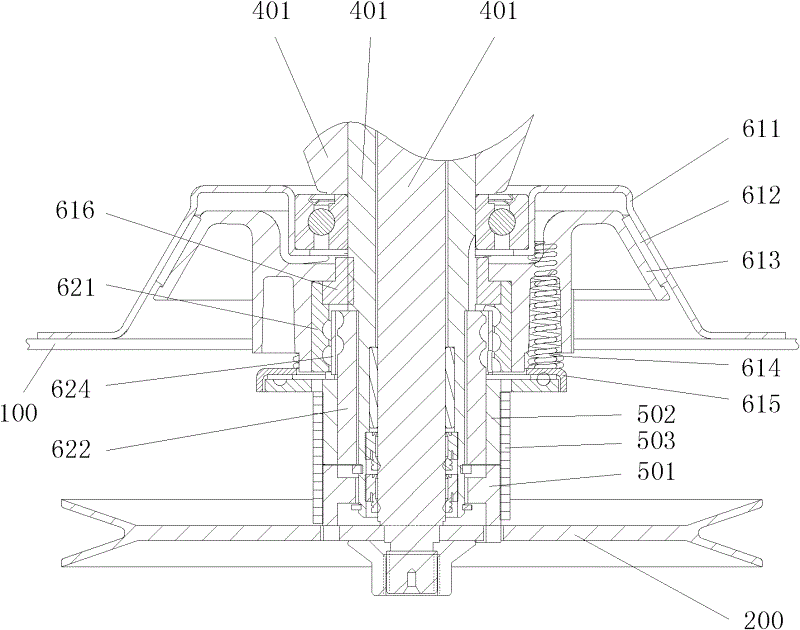

[0037] See Figure 1 to Figure 3 , the present invention has a mounting plate 100 connected with the washing machine shell, a driving pulley 200, a spindle assembly 300 fixedly connected with the washing machine pulsator, a bushing 400 fixedly connected with the washing machine inner tub, a clutch device 500 and a braking device 600, the spindle assembly The lower end of 300 is fixedly connected with the drive pulley 200, the shaft sleeve 400 is coaxially arranged to rotate with the main shaft assembly 300, and the lower part of the shaft sleeve 400 is connected with the drive pulley 200 through the clutch device 500; the main shaft assembly 300 has an input shaft 301 and an output shaft 302, and the input shaft Between the shaft 301 and the output shaft 302, a planetary gear reduction assembly 330 and a forward and reverse output assembly 340 are arranged. The brake device 600 has a cone-disc brake mechanism 610 and a brake control mechanism 620; The connected frustum flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com