Ultraviolet wear resistant primer and preparation method thereof

A wear-resistant primer and photoinitiator technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient wear-resistant hardness of the paint, blurred board surface, and increased overall cost, and achieve convenient processing, The formula is simple and reasonable, and the effect of wear resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

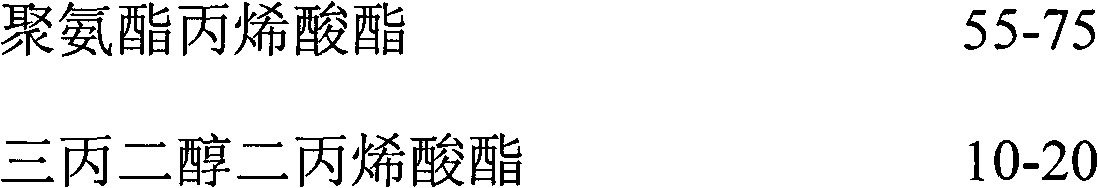

[0023] The UV wear-resistant primer of the present invention consists of the following components in parts by weight:

[0024]

[0025]

[0026] Preparation method: Mix and dissolve tripropylene glycol diacrylate and trimethylolpropane triacrylate according to the above ratio, then add photoinitiator and stir again, then add polyurethane acrylate and mix and stir, then add gas phase two while stirring Silicon oxide and aluminum oxide, after adding, stir for 10 minutes, then stand still for 1-2 hours and filter through a 150-mesh filter.

Embodiment 2

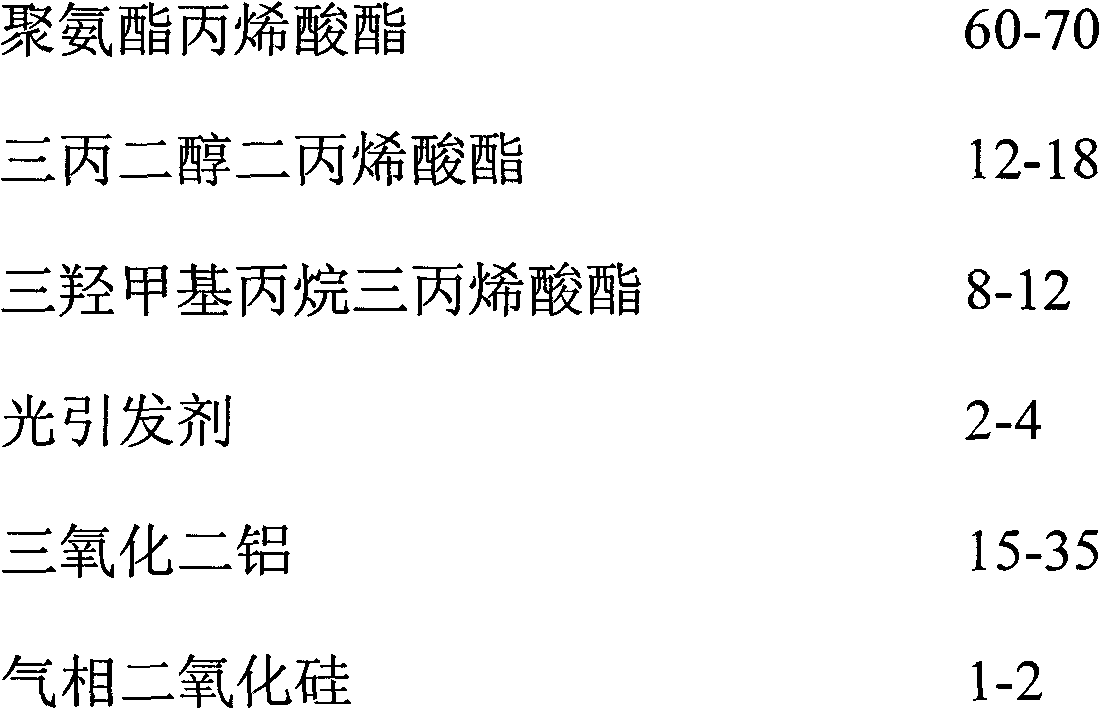

[0028] The UV wear-resistant primer of the present invention consists of the following components in parts by weight:

[0029]

[0030] Preparation method: Mix and dissolve tripropylene glycol diacrylate and trimethylolpropane triacrylate according to the above ratio, then add photoinitiator and stir again, then add polyurethane acrylate and mix and stir, then add gas phase two while stirring Silicon oxide and aluminum oxide, after adding, stir for 15 minutes, then stand still for 1-2 hours and filter through a 150-mesh filter.

Embodiment 3

[0032] The UV wear-resistant primer of the present invention consists of the following components in parts by weight:

[0033]

[0034]

[0035] Preparation method: Mix and dissolve tripropylene glycol diacrylate and trimethylolpropane triacrylate according to the above ratio, then add photoinitiator and stir again, then add polyurethane acrylate and mix and stir, then add gas phase two while stirring Silica and Al2O3, after adding, stir for 10-20 minutes, then stand still for 1-2 hours and filter through a 150-mesh filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com