Infrared low-emissivity coating material and preparation method thereof

A low-emissivity coating technology, applied in camouflage coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems not mentioned in the visible light band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific embodiments.

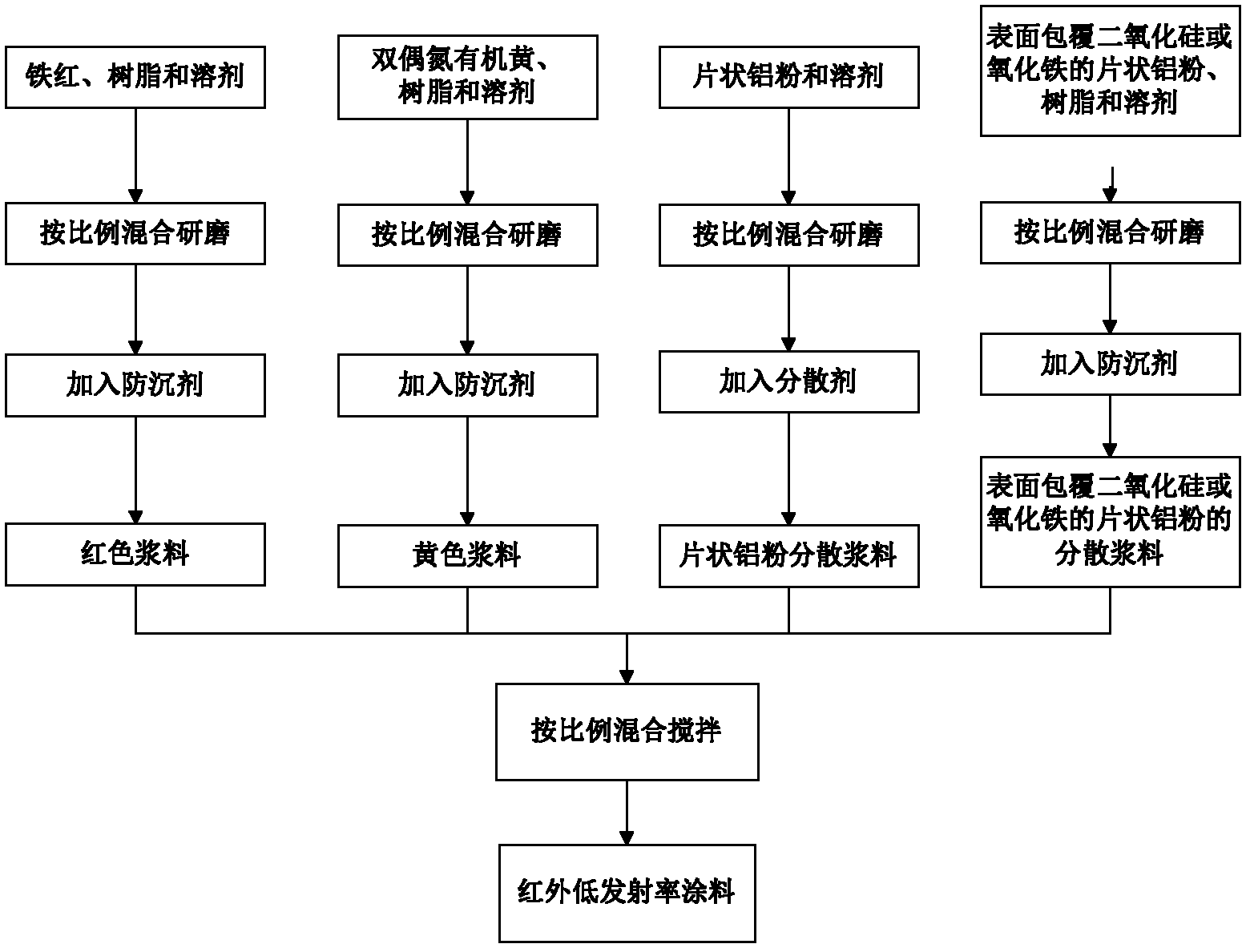

[0036] The infrared low emissivity coating provided by the invention has a preparation process as follows:

[0037] Step 1: Prepare red paste. The red slurry is mixed with iron red, resin and solvent with an average particle size between 1 and 5 microns according to the mass ratio of 30:60:10. After being ground by a sand mill for 4 hours, an amount equivalent to iron red, resin and 0.1-0.3% anti-sedimentation agent of the total mass of the three solvents.

[0038] Step 2: Prepare yellow slurry. The yellow slurry is mixed with disazo organic yellow with an average particle size between 1 and 5 microns, resin and solvent according to the mass ratio of 30:60:10, after being ground by a sand mill for 4 hours, adding the equivalent of bis The anti-sedimentation agent is made of 0.1-0.3% of the total mass of azo organic yellow, resin and solvent.

[0039]Step 3: Prepare the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com