Preparation method of chitosan-based antibacterial membrane material

A chitosan and antibacterial film technology, applied in the field of green chemistry, can solve the problems of the limited bacteriostatic effect of chitosan and the need to improve the mechanical properties of the film, so as to achieve the improvement of antimicrobial activity and strength and toughness, reduce biological irritation, enhance Antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

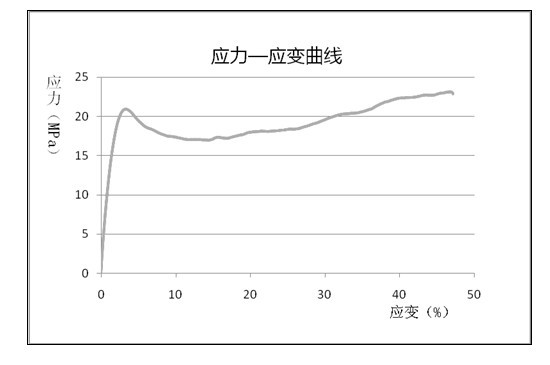

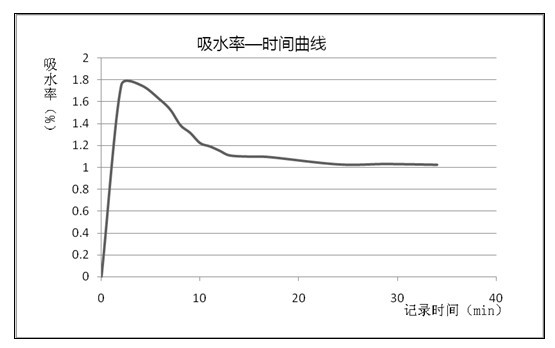

Image

Examples

Embodiment 1

[0026] 2g chitosan (molecular weight 25×10 4 Da, degree of deacetylation 85%) was dissolved in 80 ml of 1% (v / v) acetic acid solution, magnetically stirred until the solution was clear and transparent, and then left to defoam. Dissolve 2 g of povidone-iodine in 20 ml of water, and stir magnetically until the solution is clear. After the bubbles of the above two solutions are removed, the chitosan solution is slowly injected into the povidone-iodine solution, and stirred while adding. At room temperature, keep stirring for 2.5-3.5 hours until the complexation is balanced, and a uniform viscous solution of maroon color is obtained. Stop stirring, centrifuge at a speed of 6000r / min for 15min, then slowly pour out the supernatant in the centrifuge tube to spread the film. Dry at 40°C to obtain the chitosan-based antibacterial film.

Embodiment 2

[0028] 2g chitosan (molecular weight 2×10 4 Da, degree of deacetylation 85%) was dissolved in 80 ml of 1% (v / v) acetic acid solution, magnetically stirred until the solution was clear and transparent, and then left to defoam. Dissolve 1 g of povidone-iodine in 20 ml of water, and magnetically stir until the solution is clear. After the bubbles of the above two solutions are removed, the chitosan solution is slowly injected into the povidone-iodine solution, and stirred while adding. At room temperature, keep stirring for 2.5-3.5 hours until the complexation is balanced, and a uniform viscous solution of maroon color is obtained. Stop stirring, centrifuge at a speed of 6000r / min for 15min, then slowly pour out the supernatant in the centrifuge tube to spread the film. Dry at 40°C to obtain the chitosan-based antibacterial film.

Embodiment 3

[0030] 0.5g chitosan (molecular weight 25×10 4 Da, degree of deacetylation 75%) was dissolved in 80 ml of 1% (v / v) acetic acid solution, stirred by magnetic force until the solution was clear and transparent, then left to defoam. Take 0.01g of povidone-iodine and dissolve it in 20ml of water, and magnetically stir until the solution is clear. After the bubbles of the above two solutions are removed, the chitosan solution is slowly injected into the povidone-iodine solution, and stirred while adding. At room temperature, keep stirring for 2.5-3.5 hours until the complexation is balanced, and a uniform viscous solution of maroon color is obtained. Stop stirring, centrifuge at a speed of 6000r / min for 15min, then slowly pour out the supernatant in the centrifuge tube to spread the film. Dry at 40°C to obtain the chitosan-based antibacterial film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com