Dolomite four-layer composite brick and production method thereof

A technology of dolomite and layer compounding, which is applied in the field of refractory materials, can solve the problems of increasing heat consumption of clinker, increasing heat dissipation of kiln shell, and rising temperature of supporting wheel tiles, and achieves energy saving, good refractory and heat insulation effects, The effect of prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

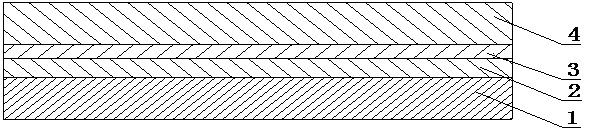

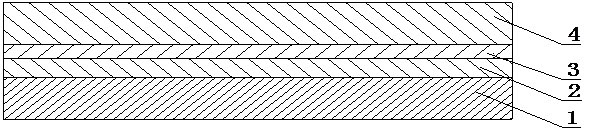

[0023] Such as figure 1 As shown, the dolomite four-layer composite brick of this embodiment is stacked with a heavy working layer 1, a first transition layer 2, a second transition layer 3, and a light heat insulation layer 4 sequentially from bottom to top.

[0024] in:

[0025] The particle gradation and mass percentage of the raw materials used in the heavy working layer 1 are: dolomite sand with a particle size of 1-3mm: 40%; dolomite sand with a particle size of less than 1mm and greater than 325 mesh: 25%; Electric dolomite sand of 325 mesh: 7.7%; fused magnesia with particle size of 325 mesh: 27.3%.

[0026] The raw material particle gradation and mass percentage content used in the first transition layer 2 are: sintered magnesia with a particle size greater than 1mm: 45%; sintered magnesia with a particle size not greater than 1mm and greater than 325 mesh: 25%; Purpose Sintered magnesium powder: 30%.

[0027] The particle size distribution and mass percentage of t...

Embodiment 2

[0038] Such as figure 1 As shown, the dolomite four-layer composite brick of this embodiment is stacked with a heavy working layer 1, a first transition layer 2, a second transition layer 3, and a light heat insulation layer 4 sequentially from bottom to top.

[0039] in:

[0040] The particle gradation and mass percentage of the raw materials used in the heavy working layer 1 are: dolomite sand with a particle size of 1 to 3 mm: 40%; dolomite sand with a particle size of less than 1 mm and greater than 325 mesh: 25.5%; Fused magnesia less than 1mm and larger than 325 mesh: 9.5%; fused magnesia with a particle size of 325 mesh: 25%.

[0041] The raw material particle gradation and mass percentage content used in the first transition layer 2 are: sintered magnesia with a particle size greater than 1mm: 45%; sintered magnesia with a particle size not greater than 1mm and greater than 325 mesh: 25%; 325 mesh sintered magnesium powder: 30%.

[0042] The particle size distributi...

Embodiment 3

[0053] Such as figure 1 As shown, the dolomite four-layer composite brick of this embodiment is stacked with a heavy working layer 1, a first transition layer 2, a second transition layer 3, and a light heat insulation layer 4 sequentially from bottom to top.

[0054] in:

[0055] The particle gradation and mass percentage of raw materials used in the heavy working layer 1 are: dolomite sand with a particle size of 1-3mm: 40%; dolomite sand with a particle size of less than 1mm and greater than 325 mesh: 35%; 325 mesh dolomite sand: 12.8%; particle size 325 mesh fused magnesia: 12.2%.

[0056] The raw material particle gradation and mass percentage content used in the first transition layer 2 are: fused magnesia with a particle size greater than 1mm: 45%; fused magnesia with a particle size not greater than 1mm and greater than 325 mesh: 25%; Fused magnesium powder with a diameter of 325 mesh: 30%.

[0057] The particle gradation and mass percentage of the raw materials use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com