Automatic steam curing system of pipe segment production line

A production line and automatic technology, applied in the field of steaming and curing, can solve the problems of high work intensity, achieve the effects of low labor intensity, reduce the risk of unqualified finished products, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

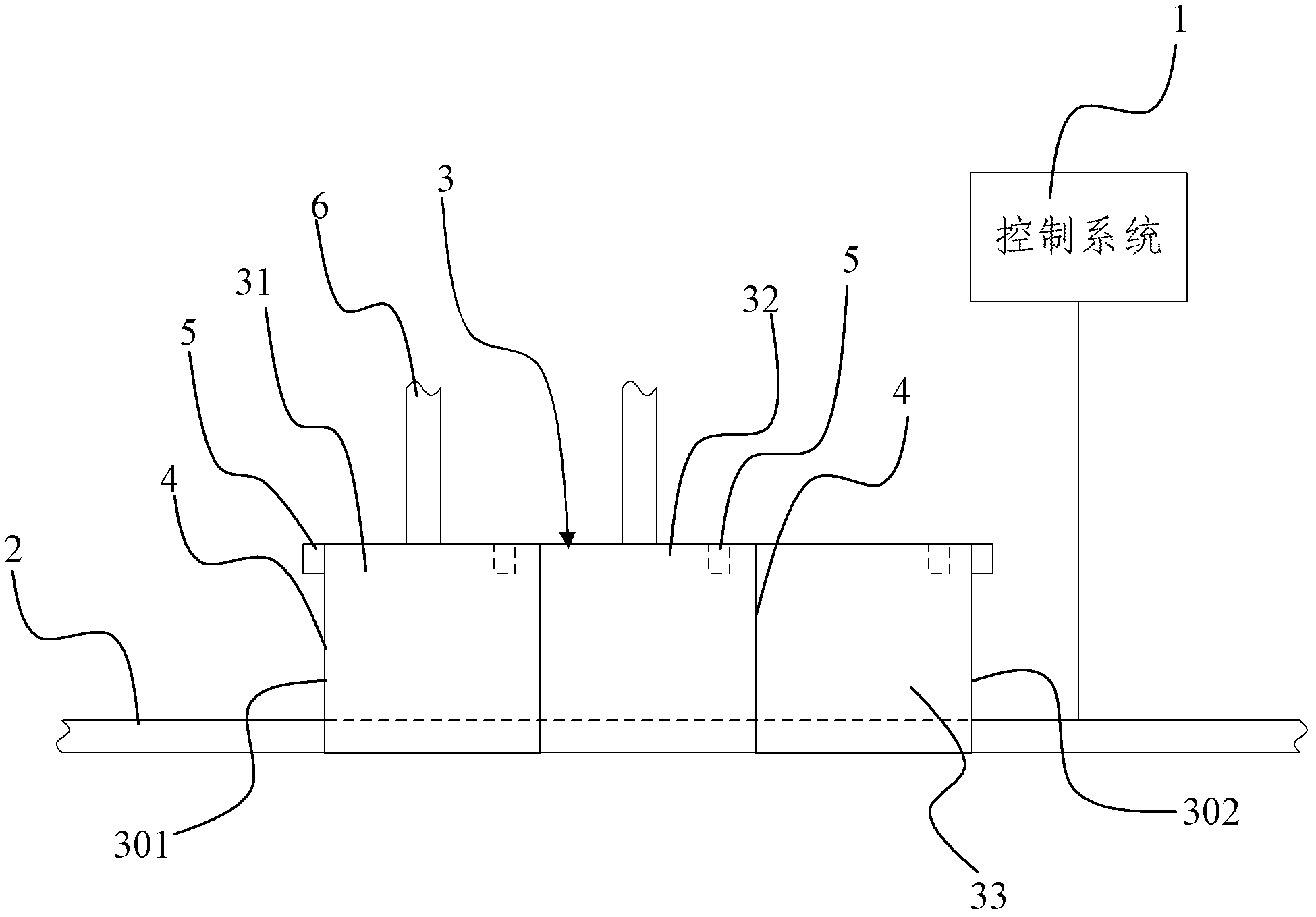

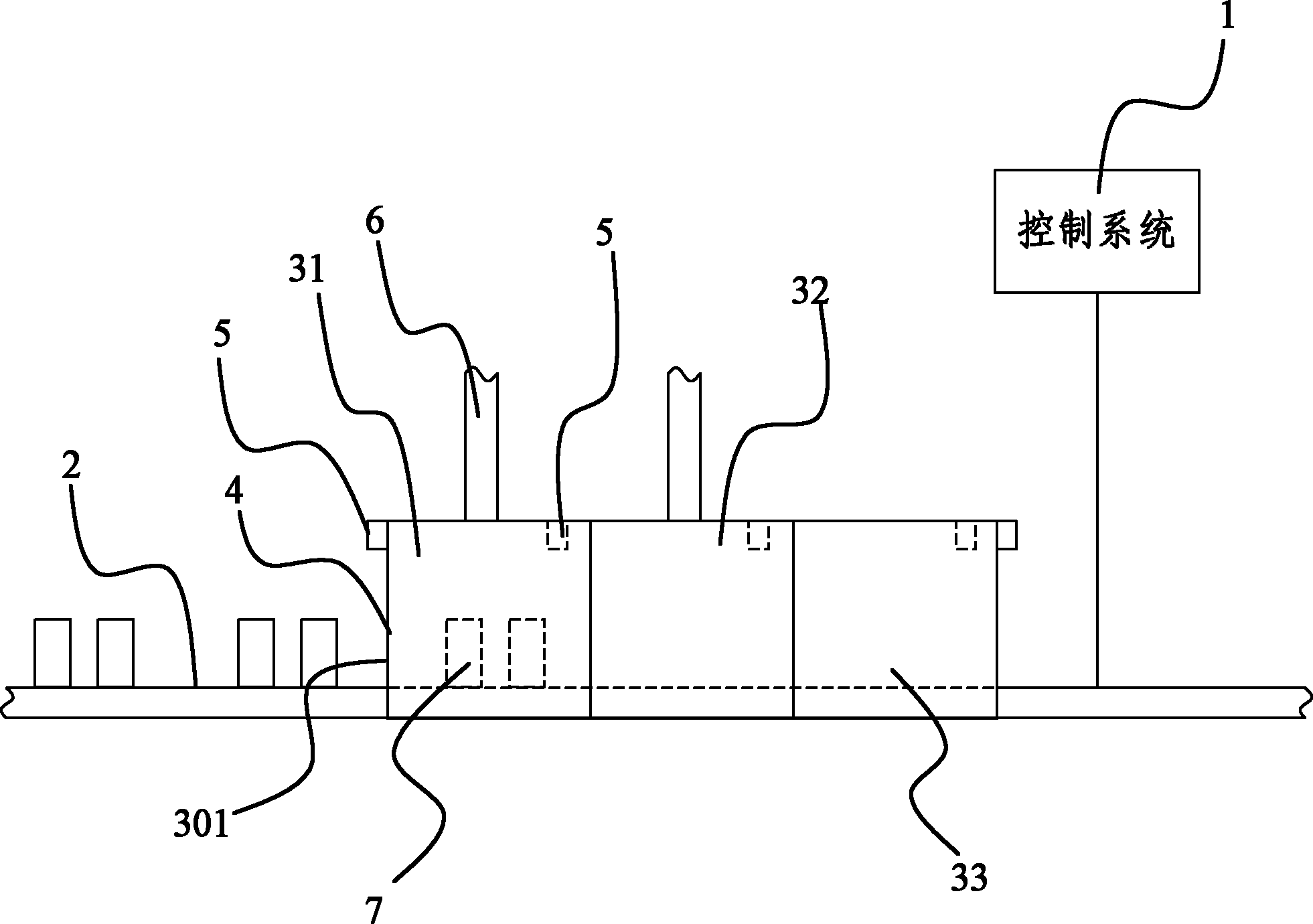

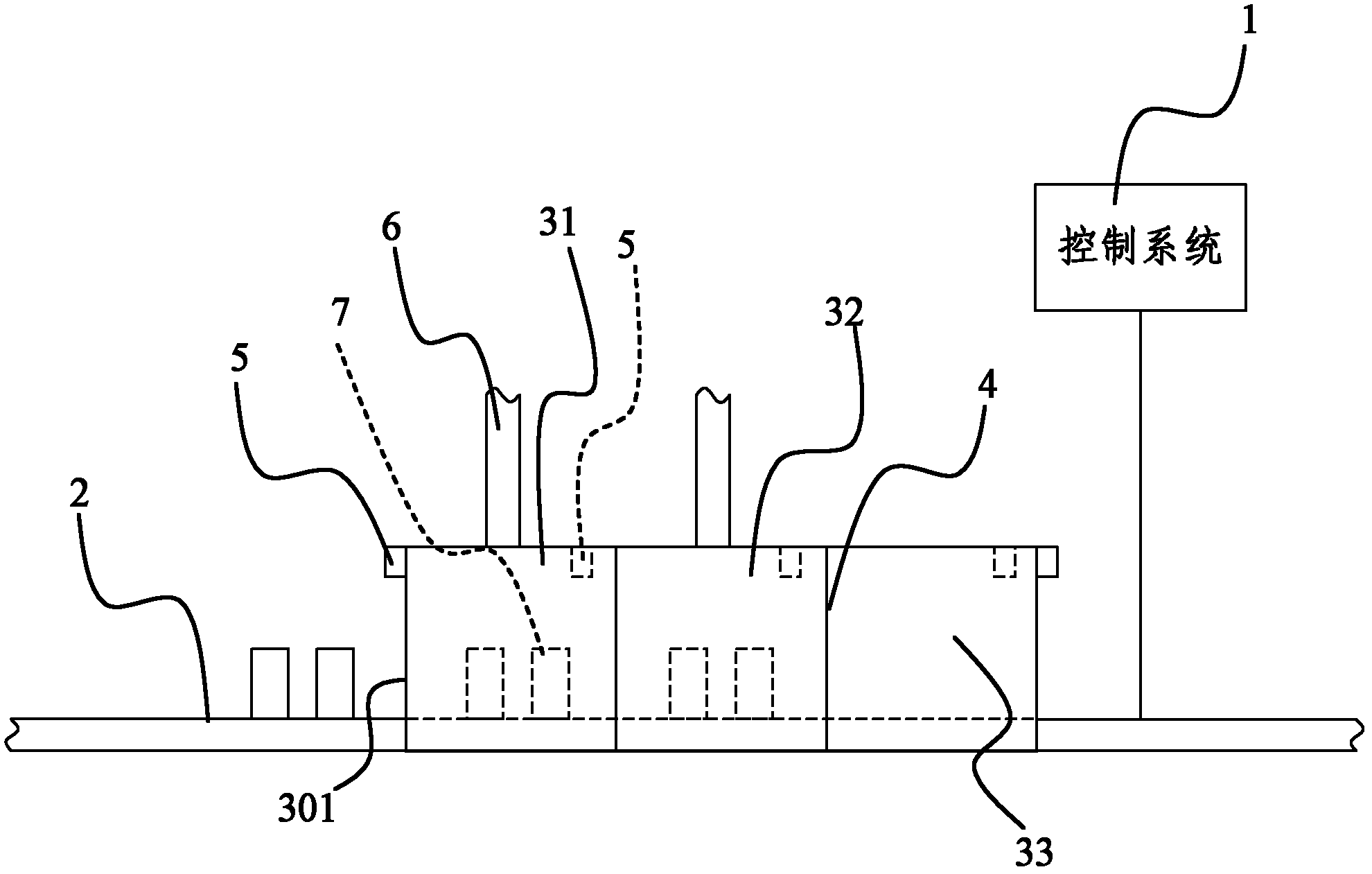

[0016] See figure 1 , an automatic steaming system for segment production line of the present invention, including a control system 1 and a box body 3 erected on the periphery of the conveyor belt 2, the box body 3 moves along the moving direction of the conveyor belt 2 through four openable heat insulation layers 4 It is divided into a heating chamber 31, a constant temperature chamber 32 and a cooling chamber 33, and the temperature sensor 5, the temperature rising chamber 31 and the constant temperature chamber are respectively arranged in the temperature rising chamber 31, the constant temperature chamber 32 and the cooling chamber 33. The chamber 32 is also communicated with a steam pipe 6 provided with a steam valve, and the control system 1 is electrically connected with the temperature sensor 5 , the steam valve (not shown in the figure) and the conveyor belt 2 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com