Grinding mechanism for abrasive belt grinding machine

An abrasive belt grinder and grinding technology, which is applied in the field of machine tools, can solve problems such as the inconstant bearing force of the abrasive belt mechanism, the complexity of the belt deviation adjustment and lateral vibration devices, and the uncontrollable tension of the abrasive belt, etc., to achieve The effect of light weight, simple structure and small shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

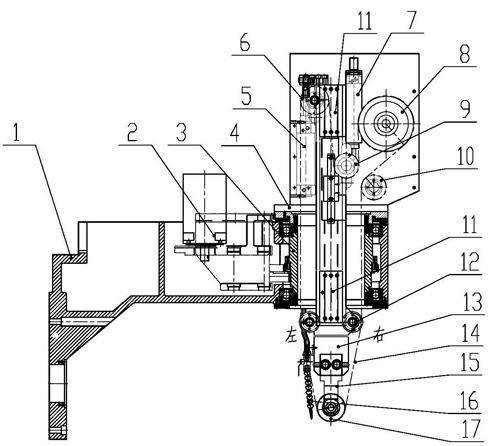

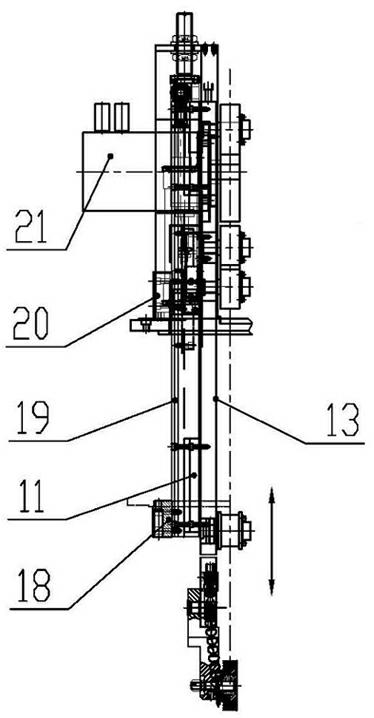

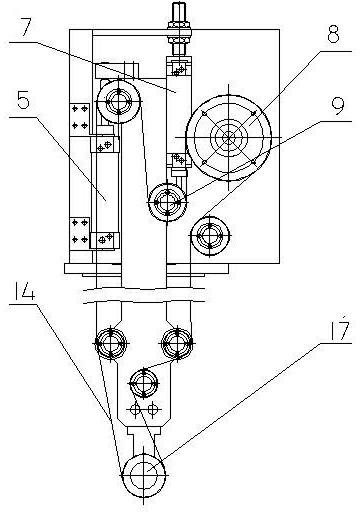

[0019] Such as Figure 1~5 As shown: the present invention is a grinding mechanism of an abrasive belt grinder, which is connected to the rotating spindle of the machine tool through a support arm 1 . Grinding mechanism is provided with driving wheel 8 and its driving device, driven wheel and contact wheel 17, abrasive belt 14 is sleeved on driving wheel 8, driven wheel and contact wheel 17, and the bottom of contact wheel 17 forms abrasive belt grinding head. The grinding mechanism includes a fixed machine base 19 and a displacement device 13, the fixed machine base 19 is connected with the end of the support arm 1, and the fixed machine base 19 is provided with a moving guide rail 11 along the vertical direction, and the displacement device 13 corresponds to the movement guide rail 11 and the fixed machine. Seat 19 movably cooperates, slides up and down. The contact wheel 17 is arranged at the bottom of the displacement device 13, that is, the abrasive belt grinding head is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com