Peeling rollers of hulling machine and driving method thereof

A driving method and technology of peeling rollers, which are applied in grain shelling, grain processing, application, etc., can solve problems such as difficulty and poor rotation speed, and achieve the effect of increasing the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

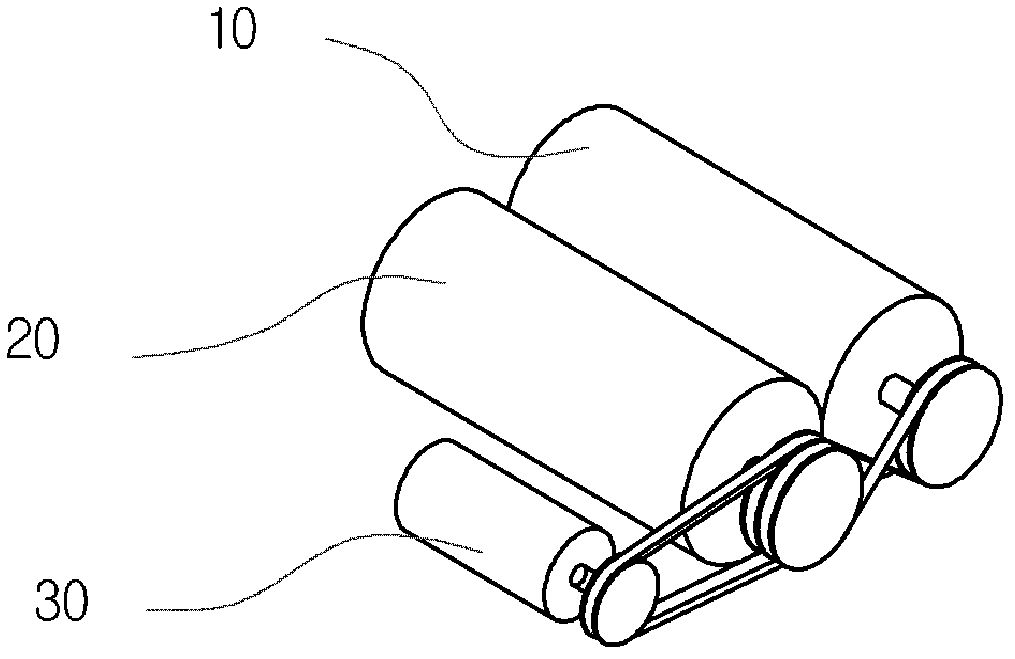

[0030] The present invention relates to a dehulling machine which divides a peeling roller used in the dehulling machine into two in the length direction so that the diameter of one side is smaller than that of the other side and faces the sides with different diameters from each other After setting each peeling roller in the same way, make a pair of peeling rollers rotate at the same speed.

[0031] The invention will be described in detail with reference to examples and drawings.

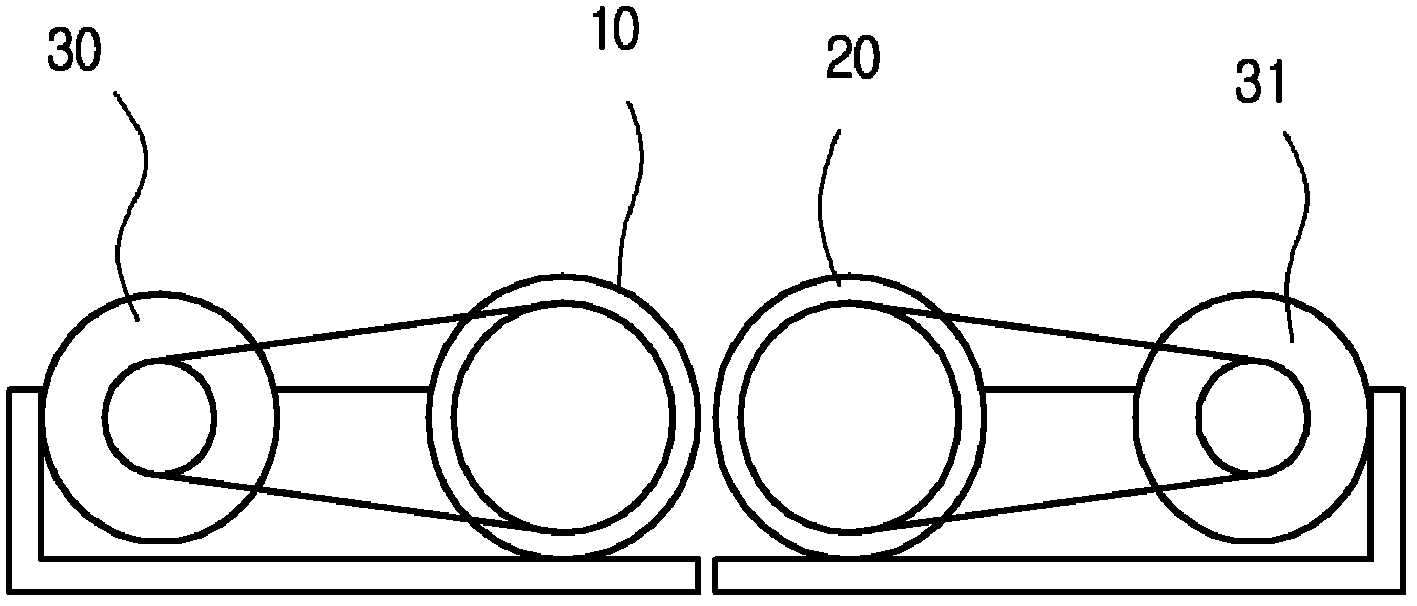

[0032] The present invention is constituted as follows: a pair of peeling rollers (60) (70) are symmetrically arranged at a certain interval, and the above-mentioned peeling rollers (60) (70) are set to a diameter (D2 ) (D3) is smaller than the diameter (D1) (D4) of the other side, and the sides with different diameters face each other.

[0033] Here, if Figure 10 and Figure 11 As shown, the diameters (D1) and (D4), the diameters (D2) and (D3) have the same diameter respectively, and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com